Speed-adjustable stirring tank with cooling and temperature sensing functions

A technology of temperature sensor and mixing tank, which is used in mixers with rotating mixing devices, mixer accessories, transportation and packaging, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

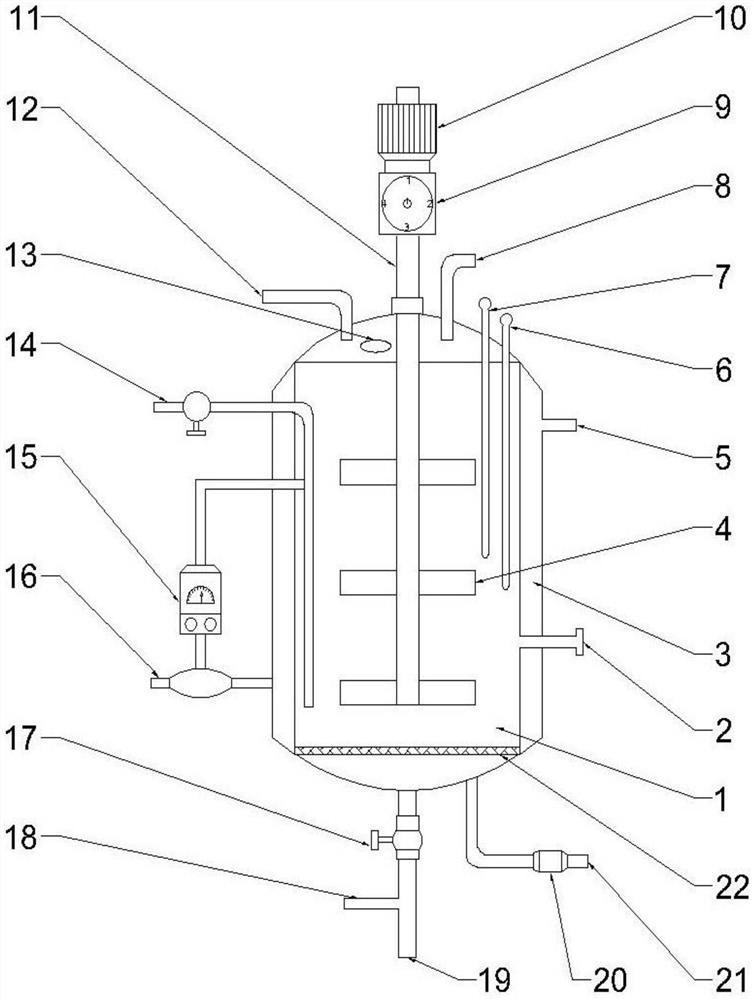

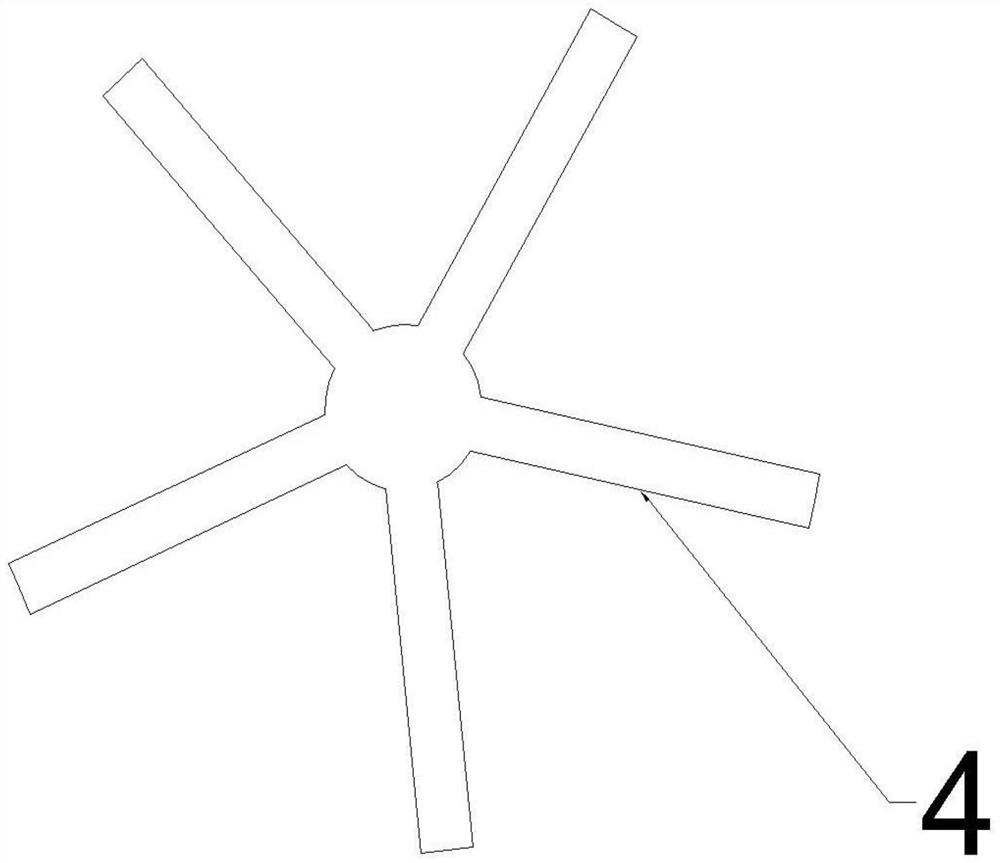

[0026] as attached figure 1 to attach Figure 5 Shown:

[0027] The invention provides a speed-adjustable stirring tank with cooling and temperature sensing functions, comprising a tank body 1, a cooling layer 3 is arranged on the outside of the tank body 1, a discharge pipe 19 is arranged below the tank body 1, and the discharge pipe A steam inlet 18 is arranged on the left side of 19, and a valve switch 17 is arranged above the steam inlet 18;

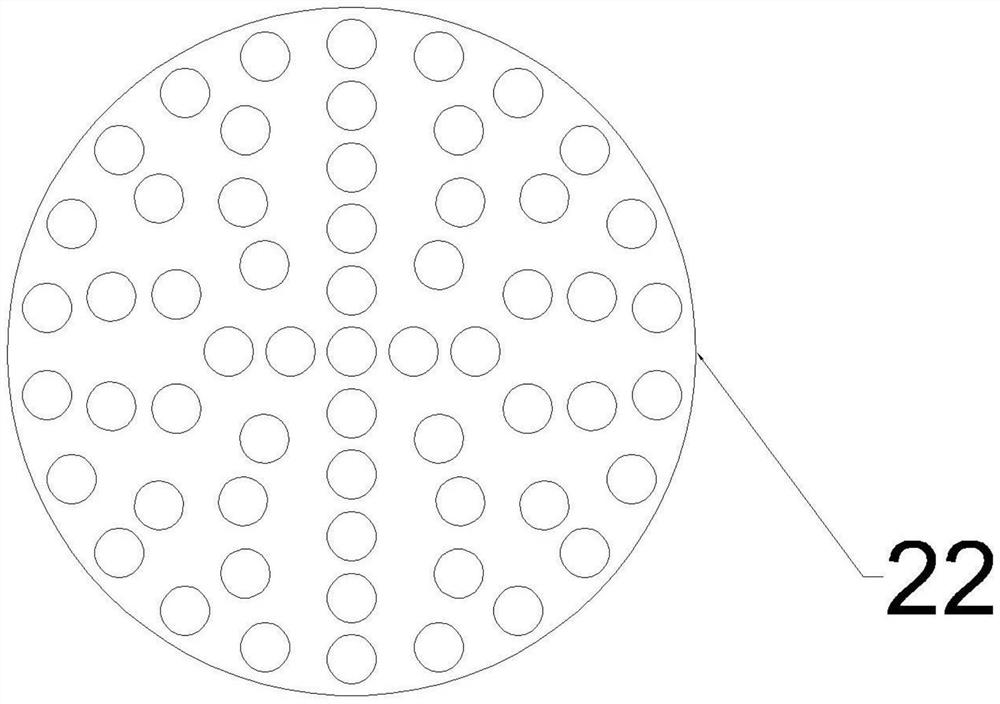

[0028] The right side of the discharge pipe 19 is provided with an air filter 20, the right side of the air filter 20 is provided with an air inlet 21, the left side of the tank body 1 is provided with a sampling tube 14, and a temperature sensor control device is provided below the sampling tube 14 15. A cooling water inlet 16 is provided below the temperature sensor control device 15;

[0029] The right side of the tank body 1 is provided with a biosensor 2, the top of the biosensor 2 is provided with a cooling water outlet 5, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com