Cooling and noise-reducing case

A cooling and noise reduction, casing technology, applied in the casing/cover/support, electromechanical device, cooling/ventilation device, etc., can solve the problems of inconvenient motor installation, time-consuming and laborious, etc. Good noise cancellation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

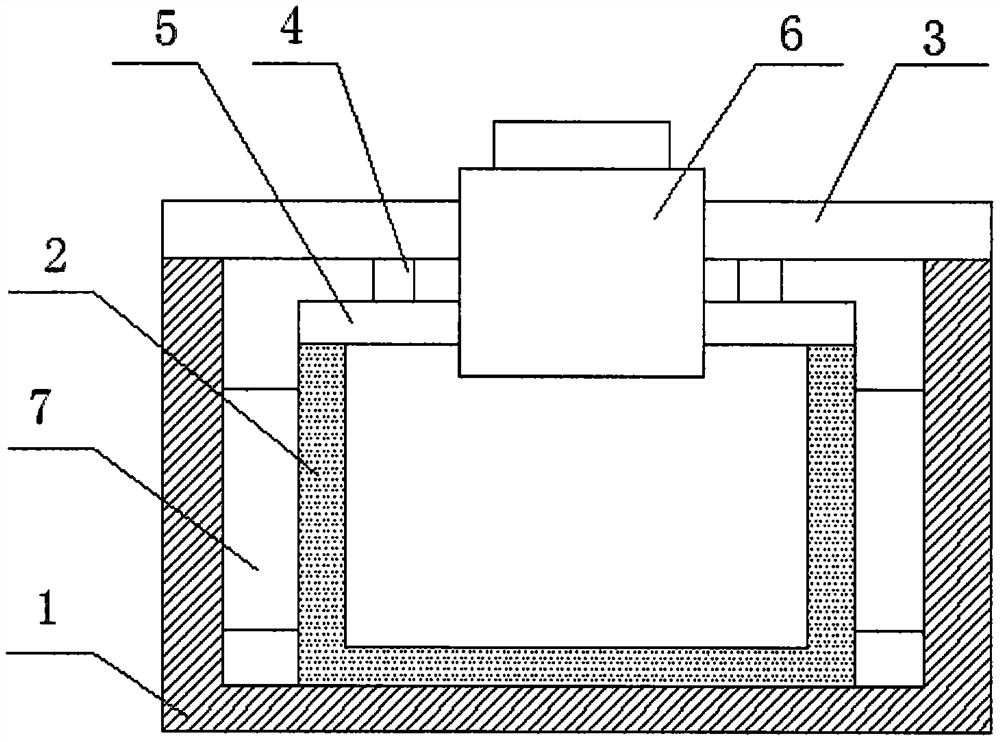

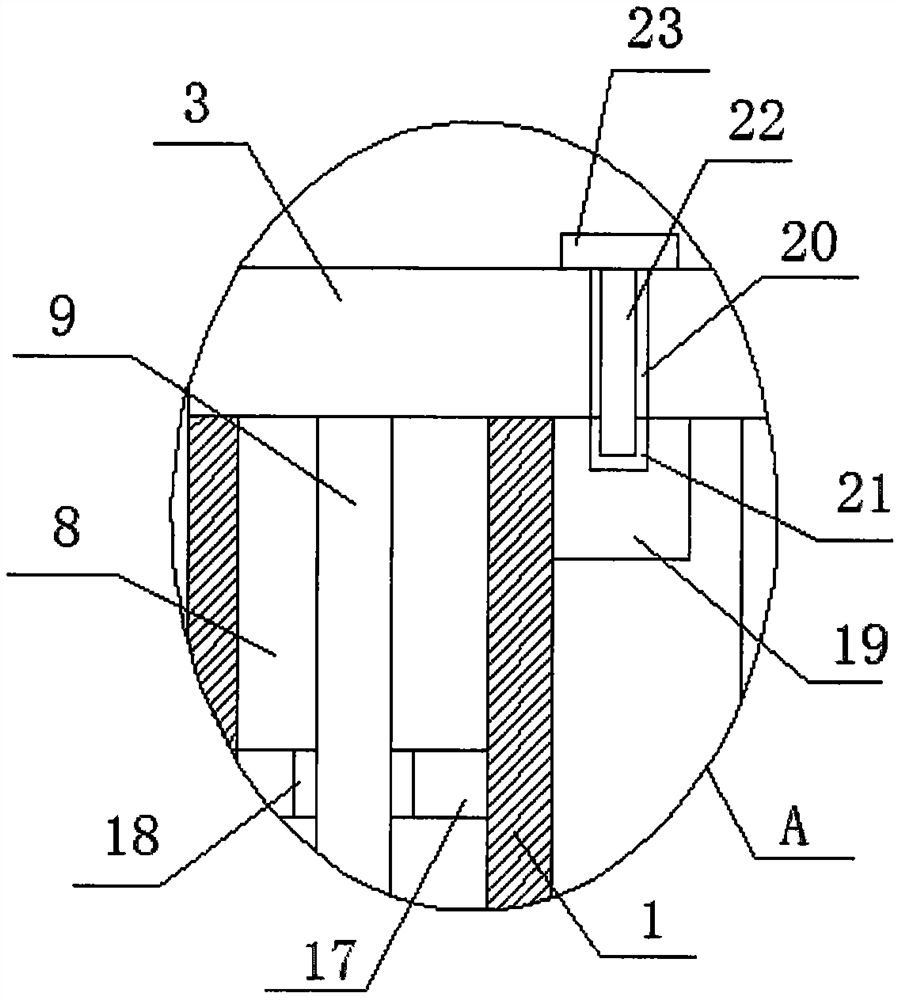

[0021] refer to Figure 1-3 , a casing for reducing temperature and noise, comprising an outer casing 1 and an inner casing 2, one side and the top side of the outer casing 1 and the inner casing 2 are all openings, and the inner casing 2 is slidably installed on the outer casing 1 On the inner wall of the bottom side, an outer cover plate 3 is placed on the top side of the outer shell 1, two connecting rods 4 are fixedly installed on the bottom side of the outer cover plate 3, and the same inner cover plate is fixedly installed on the bottom ends of the two connecting rods 4 5. The inner cover 5 is compatible with the top side of the inner shell 2, and the outer shell 1 is provided with a mounting groove 8, and a moving rod 9 is installed in the mounting groove 8, and the top end of the moving rod 9 is fixedly installed on the outer cover 3 On the bottom side of the mounting groove 8, a mounting hole 10 is opened on one side of the inner wall, and a gear 11 is installed in th...

Embodiment 2

[0027] refer to Figure 1-3 , a casing for reducing temperature and noise, comprising an outer casing 1 and an inner casing 2, one side and the top side of the outer casing 1 and the inner casing 2 are all openings, and the inner casing 2 is slidably installed on the outer casing 1 On the inner wall of the bottom side, an outer cover plate 3 is placed on the top side of the outer shell 1, and two connecting rods 4 are fixedly installed on the bottom side of the outer cover plate 3 by welding, and the bottom ends of the two connecting rods 4 are fixedly installed by welding There is the same inner cover plate 5, the inner cover plate 5 is adapted to the top side of the inner casing 2, the outer casing 1 is provided with a mounting groove 8, and a moving rod 9 is movably installed in the mounting groove 8, and the top of the moving rod 9 It is fixedly installed on the bottom side of the outer cover plate 3 by welding, and a mounting hole 10 is opened on the inner wall of one sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com