Fixing cover for double-wire clamp

A technology of double wire clamp and fixed cover, which is applied in cable installation, cable suspension device, overhead installation, etc. It can solve the problems of poor tightness of suspension wire clamp, inability to reduce accident losses, difficulty in providing sufficient clamping force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

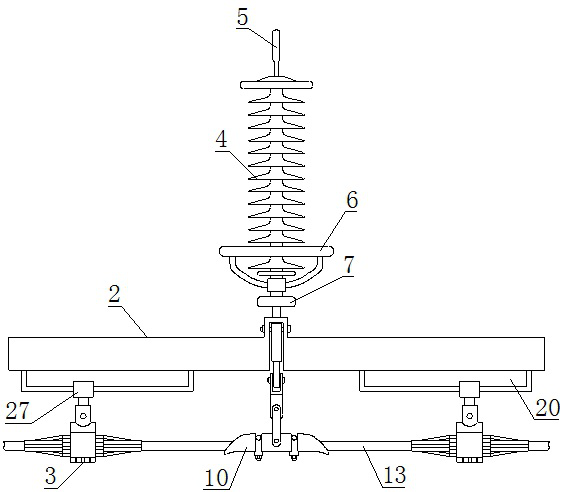

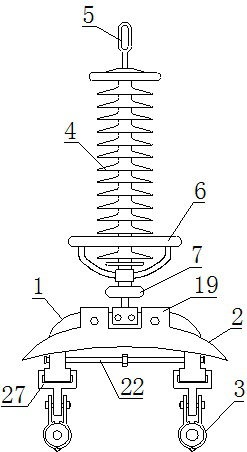

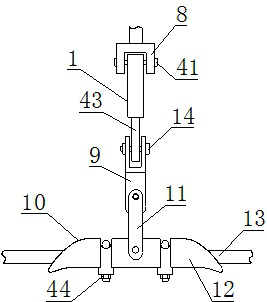

[0030] Such as Figure 1-12 As shown, the fixed cover for the double wire clamp includes a chassis 1, a cover plate 2 and a clamping seat 3, a fixed block 7 is arranged above the chassis 1, and an insulator string 4 is arranged above the fixed block 7, so A clamping plate 8 is provided below the fixed block 7, a through hole A39 is provided on the upper side of the chassis 1, a clamp shaft 41 is provided inside the through hole A39, and through holes are provided on both sides of the through hole A39. B40, the lower side of the chassis 1 is provided with a lead-out head 43, the lower end of the lead-out head 43 is provided with a traction seat 9, the lower side of the traction seat 9 is provided with a traction plate 42, and the traction plate 42 A suspension clamp 10 is provided below, a hanging ring 11 is provided on the upper side of the suspension clamp 10, a base 12 is provided on the lower side of the hanging ring 11, and a hoop 16 is provided on the inner side of the ba...

Embodiment 2

[0039] Such as Figure 1-12 As shown, the fixed cover for the double wire clamp includes a chassis 1, a cover plate 2 and a clamping seat 3, a fixed block 7 is arranged above the chassis 1, and an insulator string 4 is arranged above the fixed block 7, so A clamping plate 8 is provided below the fixed block 7, a through hole A39 is provided on the upper side of the chassis 1, a clamp shaft 41 is provided inside the through hole A39, and through holes are provided on both sides of the through hole A39. B40, the lower side of the chassis 1 is provided with a lead-out head 43, the lower end of the lead-out head 43 is provided with a traction seat 9, the lower side of the traction seat 9 is provided with a traction plate 42, and the traction plate 42 A suspension clamp 10 is provided below, a hanging ring 11 is provided on the upper side of the suspension clamp 10, a base 12 is provided on the lower side of the hanging ring 11, and a hoop 16 is provided on the inner side of the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com