Soaking rut test accessory device and test method

A technology of rutting test and auxiliary device, which is applied in the direction of measuring device, material inspection product, and application of repeated force/pulsation force to test material strength. Inexpensive, simple structure, ingenious design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]The present invention will be further described in detail below with reference to the drawings and examples.

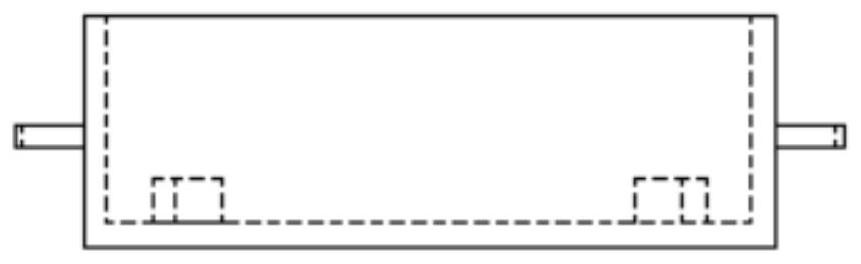

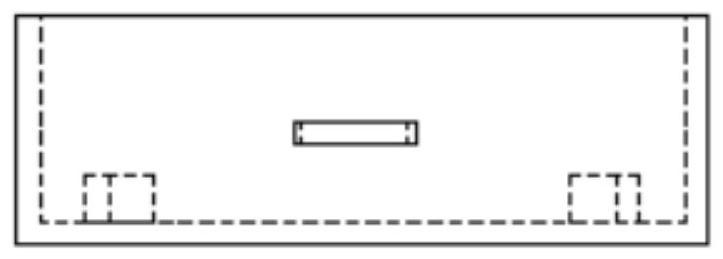

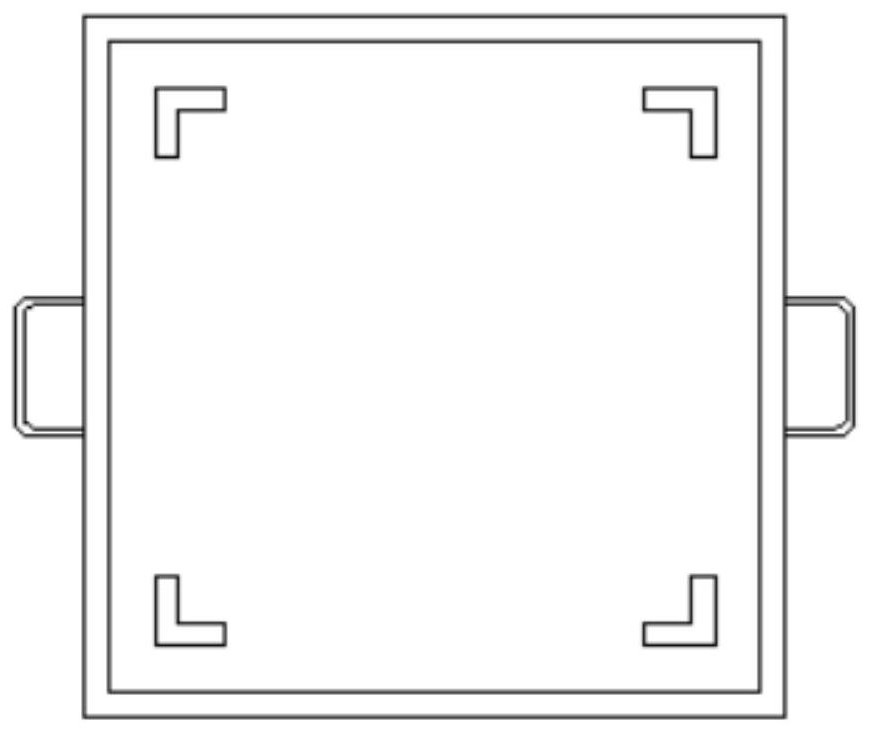

[0034]SeeFigure 1-Figure 7This embodiment provides an auxiliary device for water immersion rutting test, including a base 1, a handle and a fixed card position. The material is made of metal such as stainless steel. The metal material does not physically interact with the salt solution at a temperature of -20°C to 500°C. chemical reaction.

[0035]The base 1 is provided with a first groove, the base wall is 150mm high and 15mm thick, and the base bottom thickness is 15mm.

[0036]The handle includes a first handle 201 and a second handle 202, which are symmetrically connected to both sides of the base, and play the role of moving or lifting the entire device, so that the device can be installed on the rutting tester.

[0037]The fixed card positions include a first fixed card position 301, a second fixed card position 302, a third fixed card position 303, and a fourth fixed card ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com