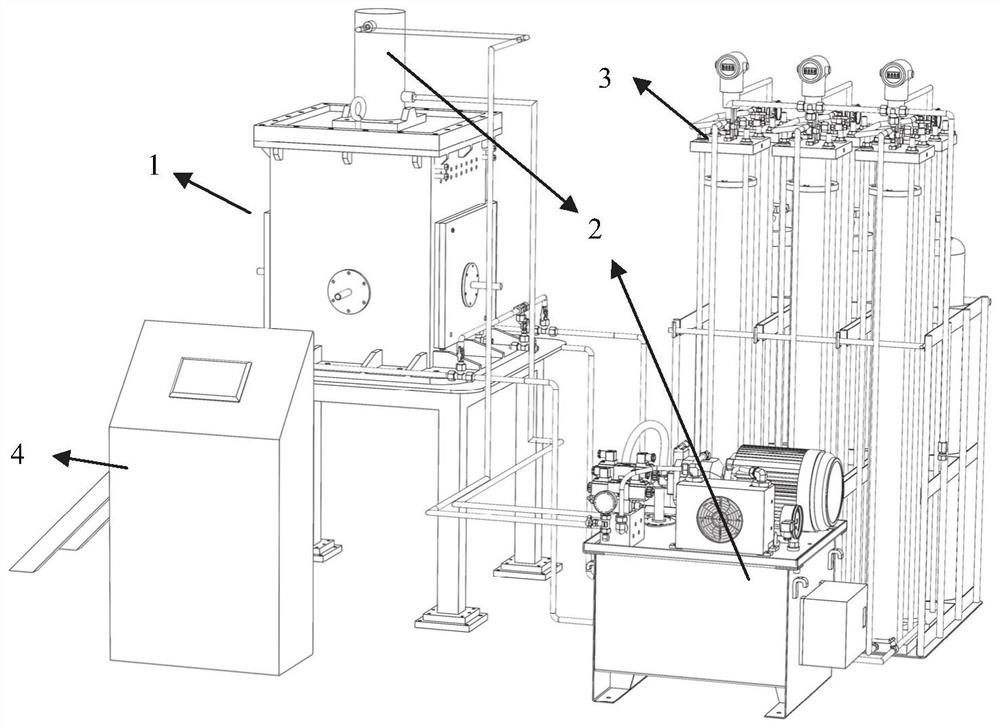

Experimental system and method for simulating seepage change in tunnel excavation under complex geological conditions

A technology for complex geological conditions and tunnel excavation, applied in the field of geotechnical engineering, it can solve the problems of single hydraulic loading form, the inability to directly observe and study the stress-seepage phenomenon, and the single test function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0084] refer to Figure 14(a)-Figure 14(c) As shown, the seepage field of surrounding rock under different seepage pressures is simulated. Pressure sensors 36 and / or osmotic pressure sensors 37 are arranged in different sections of the box, for example, a plurality of osmotic pressure sensors are arranged in section a, at least two pressure sensors are arranged in section b, and a plurality of pressure sensors are arranged in the transverse centerline of section a For the osmotic pressure sensor, multiple osmotic pressure sensors are set on the vertical center line, and four osmotic pressure sensors are set on the circle with the center of the box as the center (the osmotic pressure sensor is also set at the center of the circle), and the radius is set; section b Two pressure sensors are arranged on the central transverse centerline, the pressure sensor 36 is used to monitor the loading condition of in-situ stress, and the seepage pressure sensor 37 is used to monitor the chan...

example 2

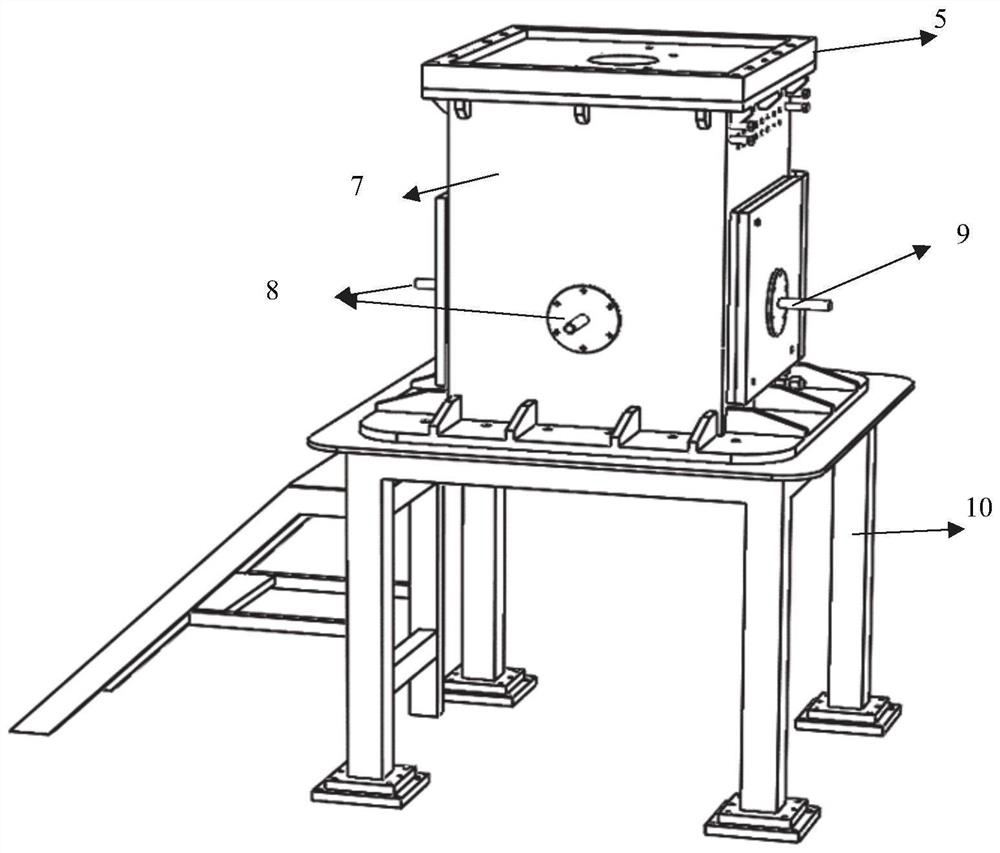

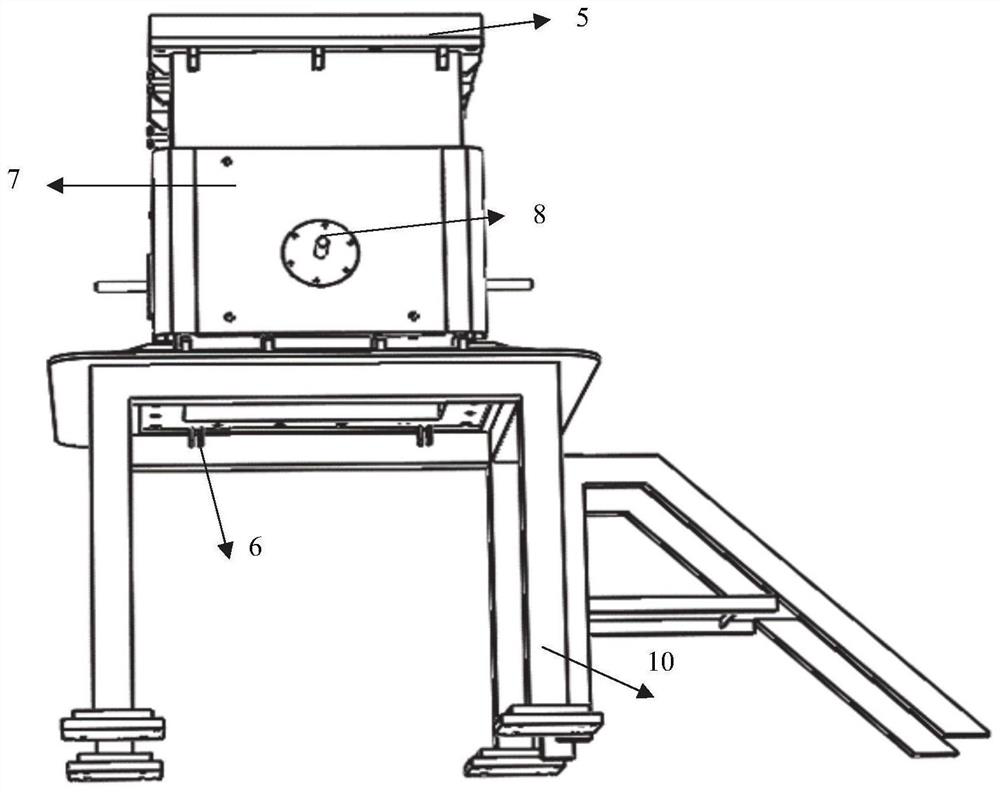

[0087] As shown in Fig. 15(a) and Fig. 15(b), the seepage evolution of surrounding rock during tunnel excavation is simulated. The osmotic pressure sensor 37 and the pressure sensor 36 are arranged alternately up and down on different sections of the test material. The pressure sensor 36 is used to monitor the loading of in-situ stress, and the osmotic pressure sensor 37 is used to monitor the change of seepage pressure in the model body. The water pressure is simulated by inserting the hollow plugs 9 into the left and rear box holes 18. The water pressure of the water-containing structure is provided by the osmotic pressure loading unit 3, and the tunnel excavation is realized through the front box holes 18. By analyzing the data collected by the seepage pressure sensor 37 and the pressure sensor, the stress-seepage evolution law of the surrounding rock during the tunnel excavation process is analyzed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com