Water-swelling waterproof type maintenance water stop system

A water-swelling and water-blocking technology, applied in the direction of pipes/pipe joints/fittings, mechanical equipment, pipe components, etc., can solve the problems of collapse, poor water-stop effect, weak glue and the viscosity of the inner wall of the pipe, etc., to reduce the impact effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

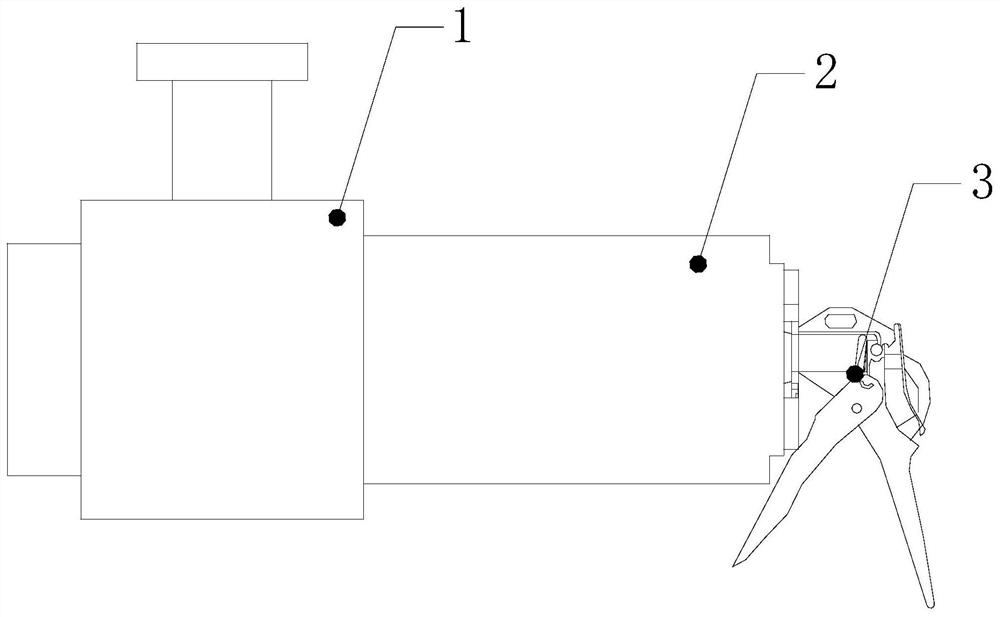

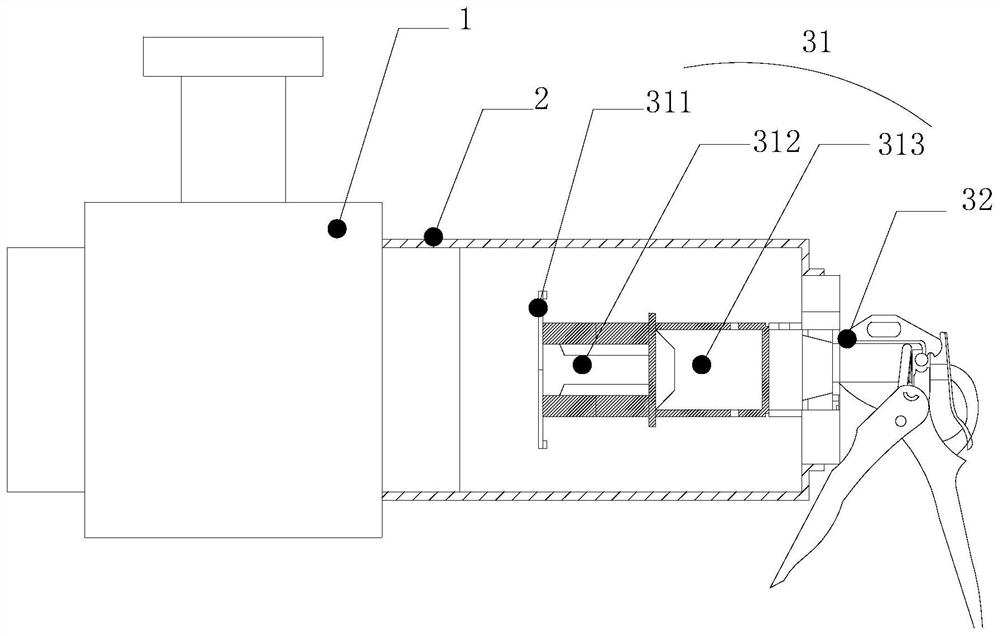

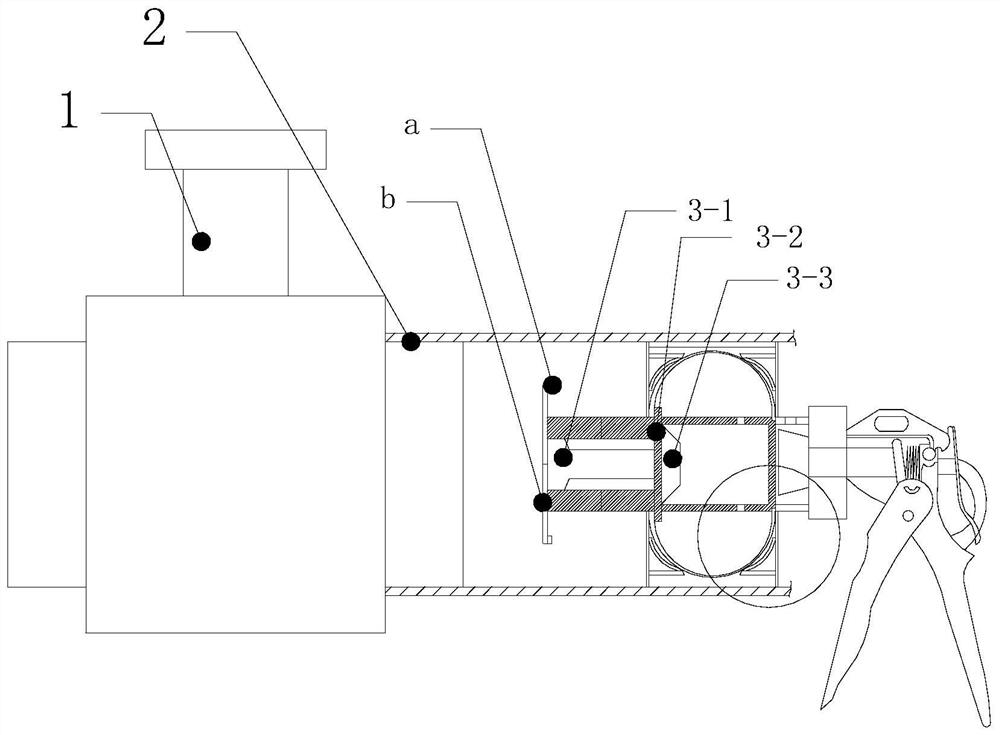

[0030] see Figure 1-Figure 8 , a water-swelling water-proof maintenance water-stop system, the present invention provides a water-swellable water-proof maintenance water-stop system, its structure includes a valve 1, a pipeline 2, a bifurcated water-stop structure 3, the pipeline 2 A valve 1 is installed at one end of the pipe 2, and a bifurcated water-stop structure 3 is installed at the other end of the pipeline 2. The bifurcated water-stop structure 3 is movably attached to the inner wall of the pipeline 2, and the bifurcated water-stop structure 3 is provided with A double water stop structure 31 and a switch 32, the double water stop structure 31 is installed in the pipeline 2, the switch 32 is located on the outer wall of the pipeline 2, the switch 32 and the double water stop structure 31 are mechanically connected .

[0031] The double water-stop structure 31 is provided with a bifurcated clamp 311, a sealing movable structure 312, and an expansion sealing structure ...

Embodiment 2

[0044] see Figure 1-Figure 8 , a water-swelling water-proof maintenance water-stop system, the present invention provides a water-swellable water-proof maintenance water-stop system, its structure includes a valve 1, a pipeline 2, a bifurcated water-stop structure 3, the pipeline 2 A valve 1 is installed at one end of the pipe 2, and a bifurcated water-stop structure 3 is installed at the other end of the pipeline 2. The bifurcated water-stop structure 3 is movably attached to the inner wall of the pipeline 2, and the bifurcated water-stop structure 3 is provided with A double water stop structure 31 and a switch 32, the double water stop structure 31 is installed in the pipeline 2, the switch 32 is located on the outer wall of the pipeline 2, the switch 32 and the double water stop structure 31 are mechanically connected .

[0045] The double water-stop structure 31 is provided with a bifurcated clamp 311, a sealing movable structure 312, and an expansion sealing structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com