Smoke dust content model value establishing method and system of gasoline particle filter

A particle filter and a technology for establishing a method are applied in the field of establishing a model value of soot content of a gasoline particle filter, which can solve the problems of burning the particle filter affecting fuel consumption and drivability, and achieve the effect of avoiding safety risks and solving drivability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

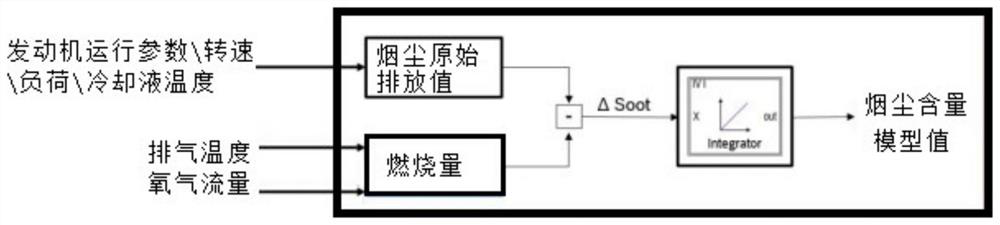

[0039] At present, the soot content is mainly calculated by the integral of the original soot emission value, such as figure 2 As shown, this method obtains the original soot emission value by measuring on the bench or the hub (the input is the engine operating parameters, such as speed, load, coolant temperature, etc.), and obtains the soot combustion rate according to the actual measurement of the exhaust temperature and oxygen flow rate , the original soot emission (soot emission) and the combustion amount (soot burn-off) are subtracted and integrated to obtain the soot content model value. This method needs to occupy a lot of bench and hub resources, and according to the existing project experience, the calculation accuracy of this method is about + / -50%, which is not high.

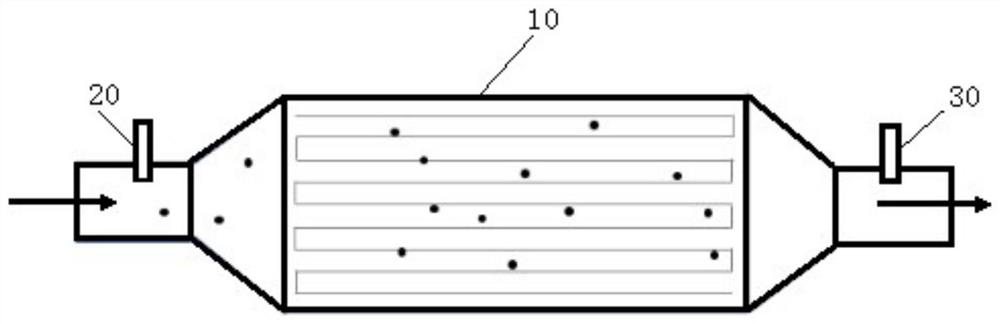

[0040] In order to solve the above problems, the present embodiment provides a method for establishing a soot content model value of a gasoline particulate filter, such as Figure 5As shown, the met...

Embodiment 2

[0045] The present invention also provides a system for establishing a model value of the soot content of a gasoline particulate filter, the system for establishing a model value of the soot content of the gasoline particulate filter includes a calculation module for the original emission value of soot, an engine sensor and a measurement module for the amount of oxygen consumed by soot combustion, Wherein: the soot original emission value calculation module measures the soot original emission value on the engine stand or the rotating hub; the engine sensor measures the soot combustion rate, and the soot combustion rate is multiplied by the combustion time to obtain the combustion amount; The soot original emission value and the combustion amount are subtracted and integrated to obtain the soot content model value; the soot combustion oxygen consumption measurement module measures the soot combustion oxygen consumption, according to the soot combustion oxygen consumption, combine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com