Anchor bolt group device for improving anti-cracking performance of power transmission tower pile foundation and manufacturing method

A technology of anti-crack performance and manufacturing method, applied in the field of transmission tower foundation, can solve the problems of indirect loss, difficult reinforcement and repair, and long repair time, and achieve the effect of low cost, convenient positioning, and preventing the development of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

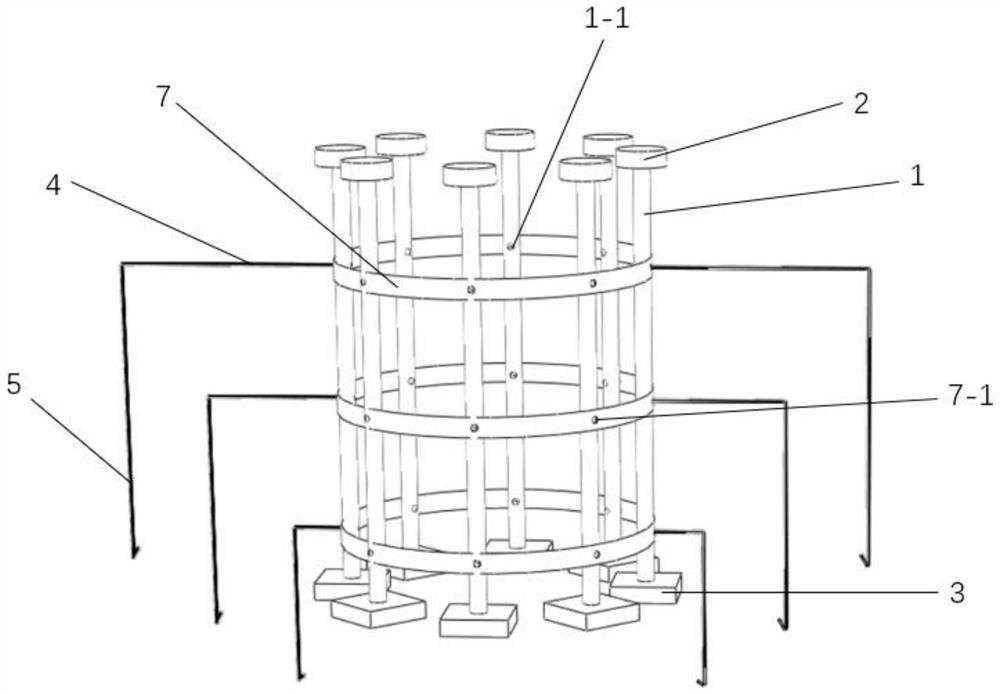

[0032] refer to Figure 1 to Figure 5 , is an anchor bolt group device and a manufacturing method for improving the anti-crack performance of transmission tower pile foundations.

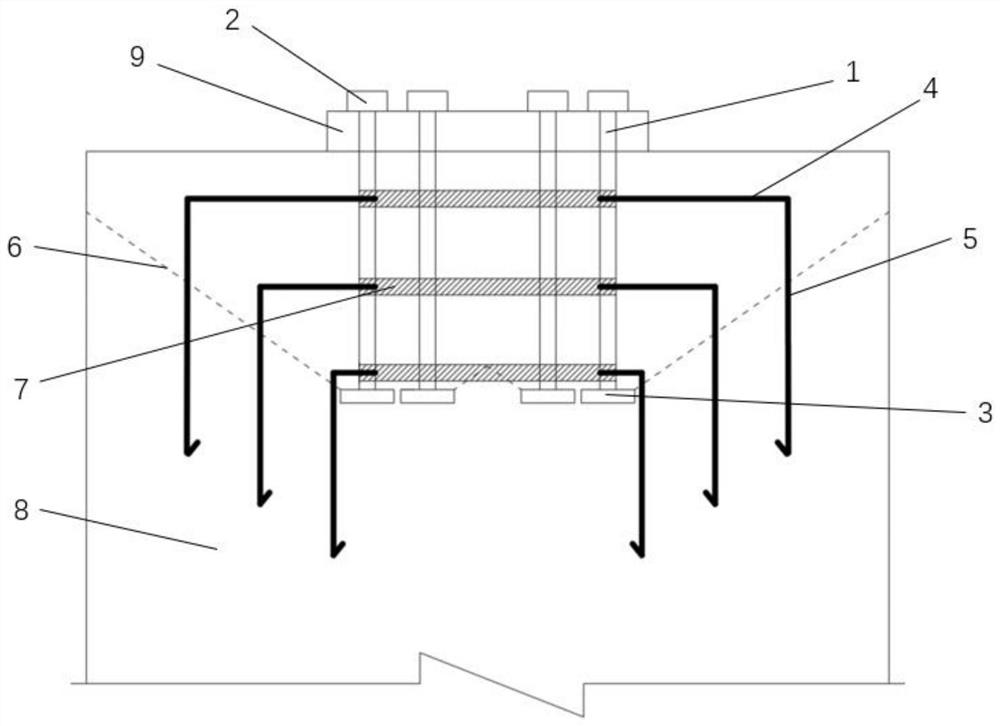

[0033] Such as figure 1 , when it is necessary to design the anti-crack performance of the transmission tower pile foundation, the device of the present invention can be selected and used before construction.

[0034] Such as Figure 4 , an anchor bolt group device for improving the anti-crack performance of the transmission tower pile foundation, its function is mainly to improve the crack resistance bearing capacity of the transmission tower pile foundation.

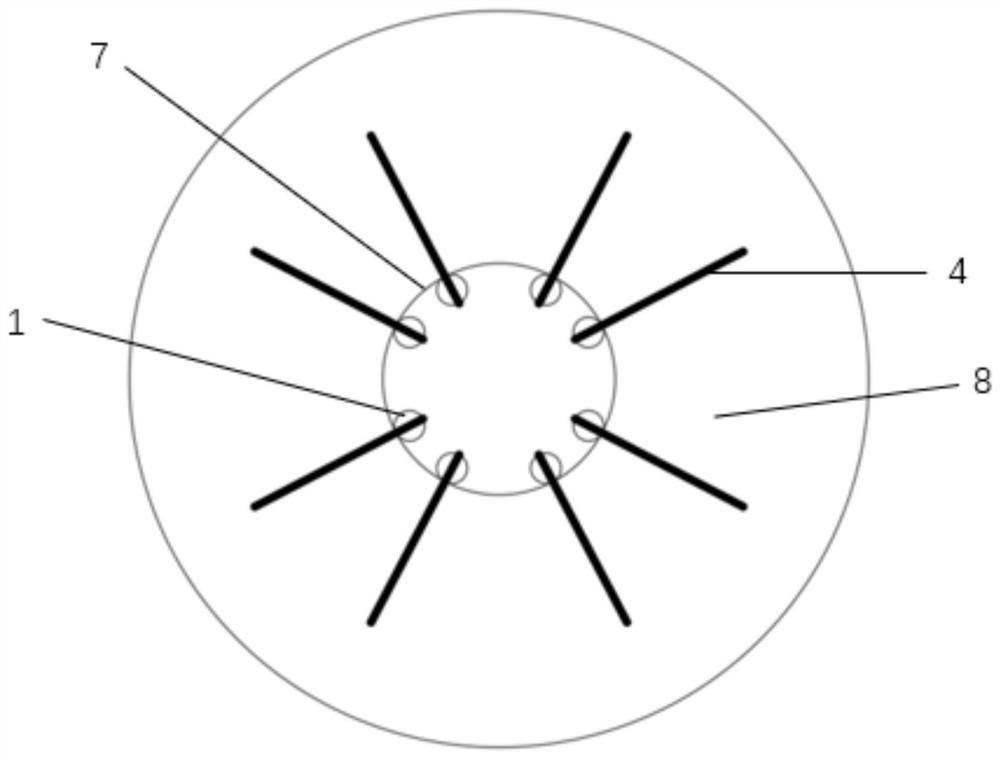

[0035] Such as image 3 On the outer side of the anchor bolt group along the height direction of the anchor bolt 1 at a certain distance, several annular steel sheets 7 are used for wrapping, and the anchor bolt 1 and the annular steel sheet 7 are drilled at corresponding positions (1-1, 7-1). Centering on the center of the anchor bolt g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com