Yarn waxing equipment for textile processing

A technology for textiles and yarns, which is applied in the field of waxing equipment for yarns used in textile processing. It can solve the problems of inconvenient yarn subsequent use, rough waxing process, and reduce yarn breakage, etc., so as to improve waxing efficiency and make waxing compact and even, waxed finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

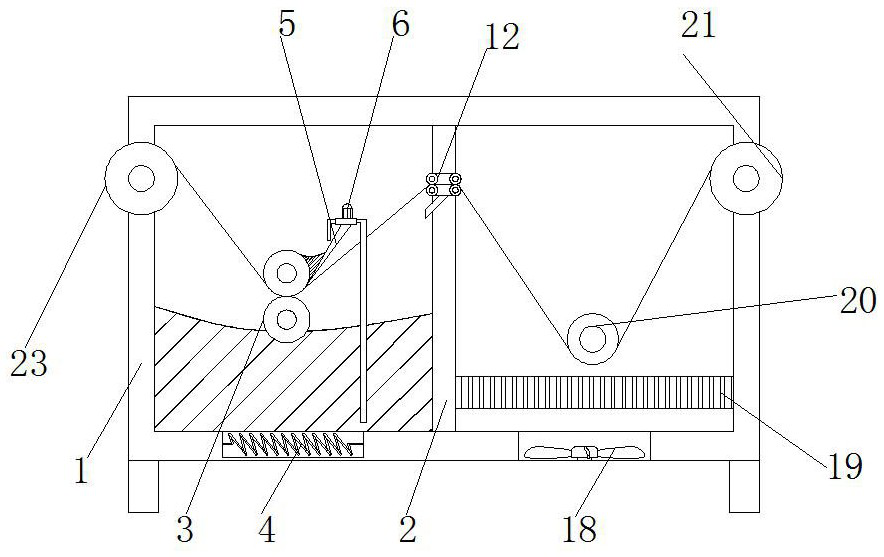

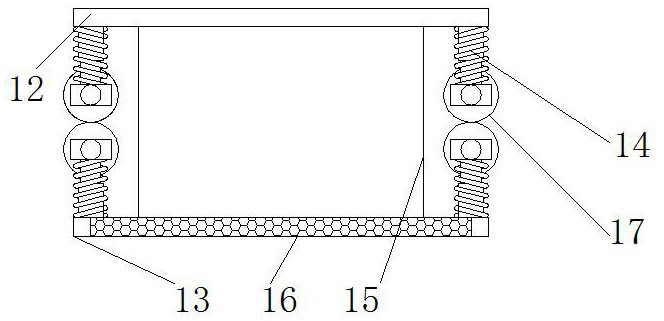

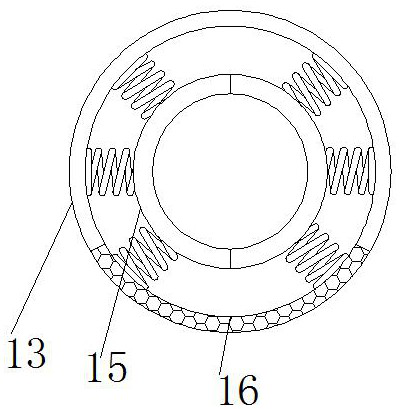

[0022] Embodiment 1, with reference to Figure 1-5 , a kind of yarn waxing equipment for textile processing, comprising a box body 1, a baffle plate 2 is fixed on the inner wall of the box body 1, and the baffle plate 2 separates the box body 1 into a waxing room and a drying room, and the waxing room is provided with an upper Waxing mechanism 3, and the bottom of the waxing chamber is provided with an installation groove, and the inner wall of the installation groove is fixed with an electric heating wire 4. The waxing mechanism 3 includes a first waxing roller 7, a second waxing roller 8, a driven gear 9, The driving gear 10 and the first servo motor 11, the inner wall of the driven gear 9 is fixed on one end of the first waxing roller 7, and the driven gear 9 meshes with the driving gear 10, and the inner wall of the driving gear 10 is fixed on the second waxing roller 8 and the output shaft of the first servo motor 11 is fixed on the inner wall of the driving gear 10 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com