Needle bar self-locking mechanism

A needle bar, self-locking technology, applied in the field of embroidery machines, can solve the problems of difficult needle bar self-locking, axial fall off, needle bar damage to mechanical parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

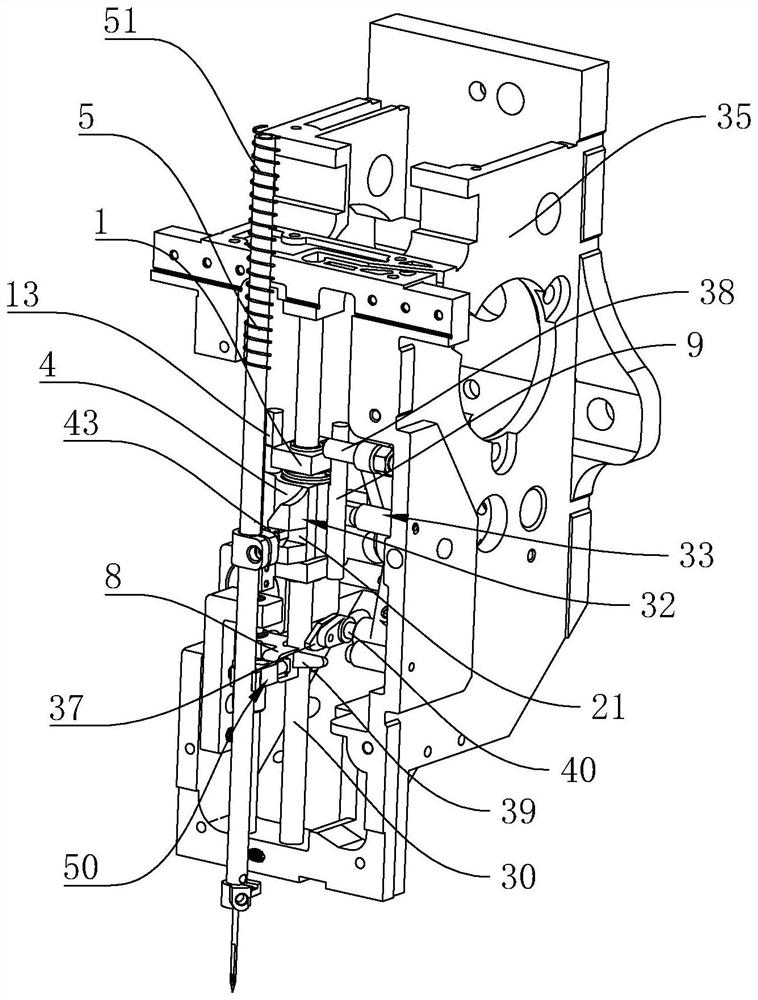

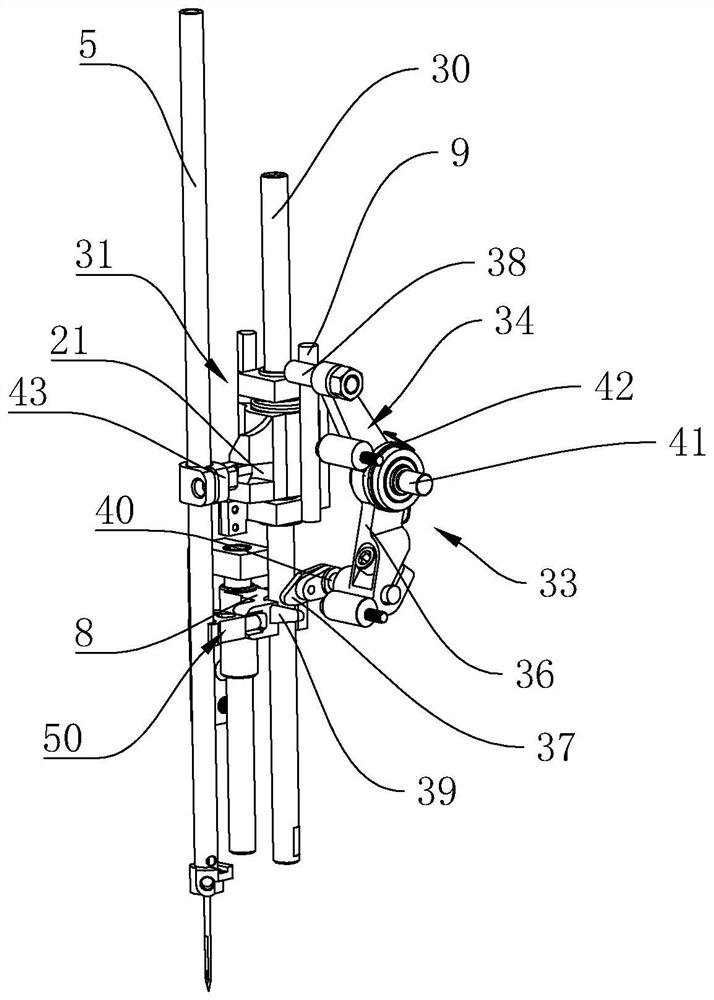

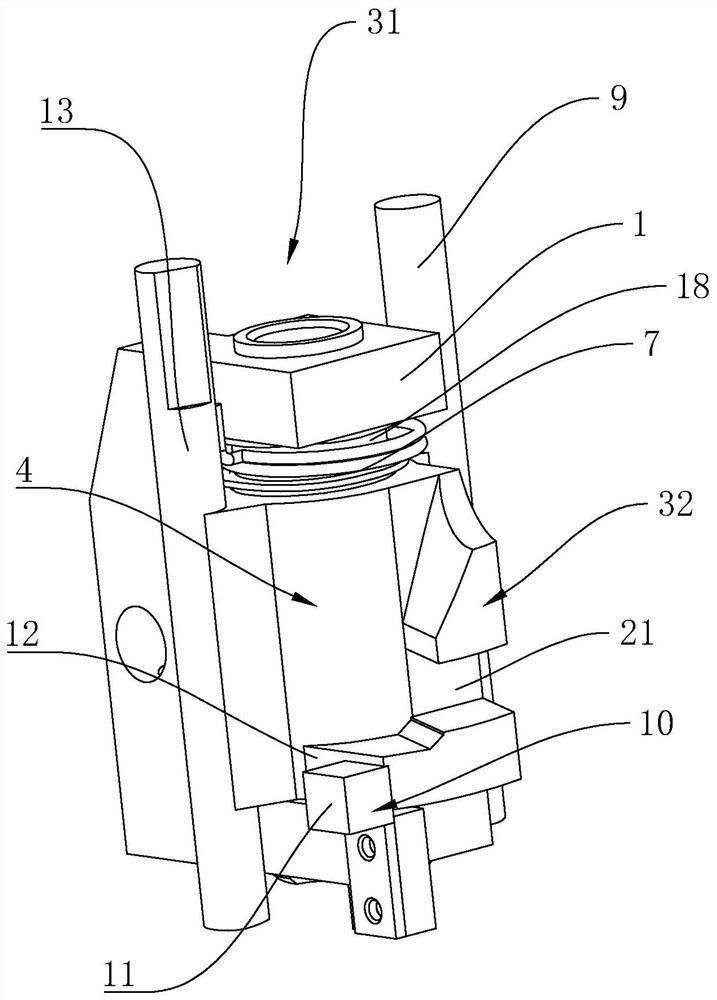

[0027] Such as Figure 1-4 as shown,

[0028] A needle bar self-locking mechanism, including a guide rod 30 vertically fixedly arranged on the machine head housing 35, on which a presser foot driver 8 and a needle bar driver 31 are axially movable, and the needle bar The driver 31 and the presser foot driver 8 are spaced apart in the vertical direction, and the needle bar driver 31 is located above the presser foot driver 8, and the needle bar driver 31 is connected to the needle bar 5 through a clutch structure 32. Between the foot driver 8 and the needle bar driver 31 is provided a linkage type clutch control structure 33 which is powered by the presser foot driver 8 to control the action of the clutch structure 32. The needle bar 5 is axially movable through the needle bar frame and An axial anti-off structure 50 is provided between the two, and a needle bar jacki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com