Composite color fixative special for apricot wine and apricot wine

The technology of a color protectant and apricot wine is applied in the field of a special compound color protectant for apricot wine and apricot wine. , good color protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Raw material preparation: select mature and intact apricot fruit, wash and remove the core, after crushing, add water according to the volume ratio of material to water at 4.5:1 to obtain pulp;

[0031] (2) Raw material pretreatment: Add pectinase in the amount of 0.45g / L to the pulp, and carry out enzymatic hydrolysis treatment at room temperature for 24 hours; after the enzymolysis is completed, add white sugar and potassium bicarbonate to adjust the pretreated fruit The pH value of the slurry is 3.5; the sugar content is 21%;

[0032] (3) Inoculation and fermentation: Inoculate D254 Nuomo yeast in the pretreated pulp at an amount of 1.2g / L, and ferment at 25°C for 7 days;

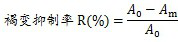

[0033] (4) Color protection and aging treatment: after the fermentation is completed, filter, add a composite color protection agent in an amount of 2.0 g / L to the filtrate, and stand at 20°C for 12 days to obtain raw wine; the composite color protection agent is obtained by mass Sodium eryth...

Embodiment 2

[0036] (1) Raw material preparation: select mature and intact apricot fruit, wash and remove the core, after crushing, add water according to the volume ratio of material to water at 4.5:1 to obtain pulp;

[0037] (2) Raw material pretreatment: Add pectinase in the amount of 0.45g / L to the pulp, and carry out enzymatic hydrolysis treatment at room temperature for 24 hours; after the enzymolysis is completed, add white sugar and potassium bicarbonate to adjust the pretreated fruit The pH value of the slurry is 3.5; the sugar content is 21%;

[0038] (3) Inoculation and fermentation: Inoculate D254 Nuomo yeast in the pretreated pulp at an amount of 1.2g / L, and ferment at 25°C for 7 days;

[0039] (4) Color protection and aging treatment: filter after the fermentation is completed, add a composite color protection agent in an amount of 1.8g / L to the filtrate, and let it stand at 25°C for 7 days to obtain raw wine; the composite color protection agent is determined by mass Sodium...

Embodiment 3

[0042] (1) Raw material preparation: select mature and intact apricot fruit, wash and remove the core, after crushing, add water according to the volume ratio of material to water at 4.5:1 to obtain pulp;

[0043](2) Raw material pretreatment: Add pectinase in the amount of 0.45g / L to the pulp, and carry out enzymatic hydrolysis treatment at room temperature for 24 hours; after the enzymolysis is completed, add white sugar and potassium bicarbonate to adjust the pretreated fruit The pH value of the slurry is 3.5; the sugar content is 21%;

[0044] (3) Inoculation and fermentation: Inoculate D254 Nuomo yeast in the pretreated pulp at an amount of 1.2g / L, and ferment at 25°C for 7 days;

[0045] (4) Color protection and aging treatment: after the fermentation is completed, filter, add a composite color protection agent in an amount of 2.3g / L to the filtrate, and stand at 18°C for 15 days to obtain raw wine; the composite color protection agent is determined by mass Sodium ery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com