Modular design integrated sewage treatment equipment

A technology of sewage treatment equipment and modular design, applied in water/sewage treatment equipment, water/sewage treatment, water/sludge/sewage treatment, etc. higher question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

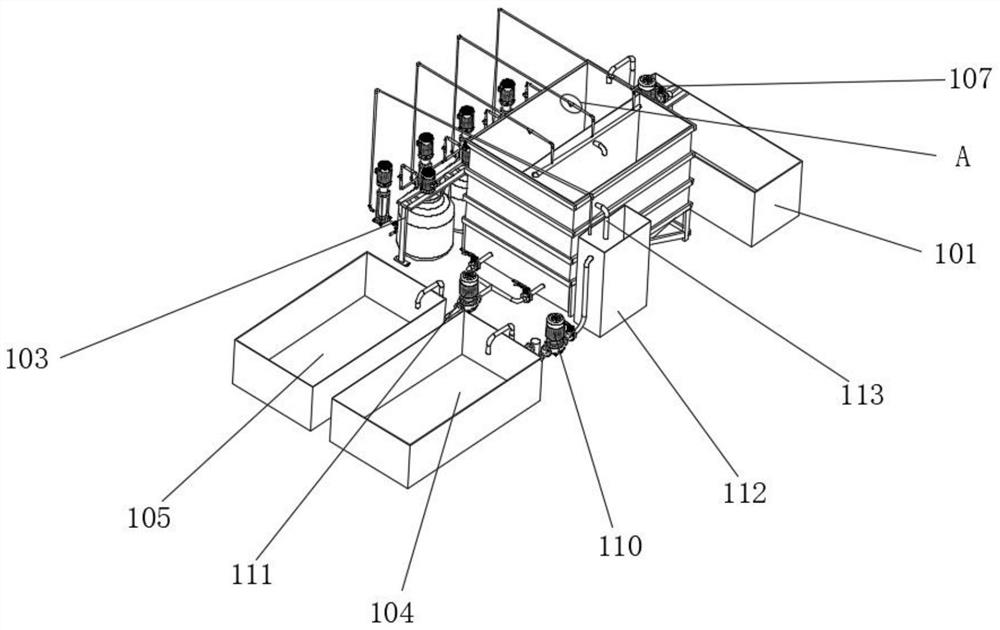

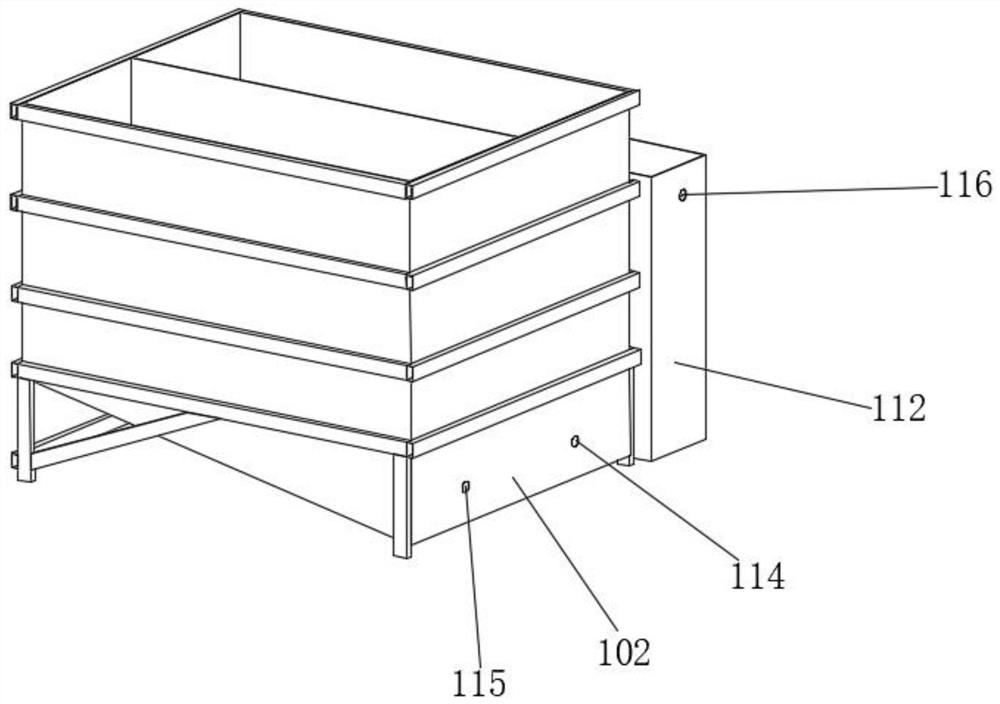

[0031] see Figure 1-7 As shown, this embodiment is a modular design integrated sewage treatment equipment, including a sewage tank 101, a treatment tank 102, a dosing mechanism 103, a clean water tank 104, a sedimentation tank 105, a mounting plate 106, a first delivery pump 107, Secondary flocculation chamber 108, primary flocculation chamber 109, second delivery pump 110, third delivery pump 111, static tank 112, one side of the sewage tank 101 is provided with a treatment box 102, one of the treatment box 102 A dosing mechanism 103 is provided on the side, and a clear water tank 104 and a sedimentation tank 105 are arranged side by side on the side of the treatment box 102 away from the sewage tank 101, and a static tank 112 is set on the side of the treatment box 102 away from the dosing mechanism 103 ;

[0032]A partition plate is installed in the inner chamber of the treatment box 102, and the inner wall of the treatment box 102 is combined with the partition plate to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com