Tobacco outer box conveying device with passing door

A technology for conveying devices and access doors, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve the problems of moisture, damage, and inconvenient storage of the outer box, and achieve the effect of improving efficiency and smooth conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A further detailed description will be made below in conjunction with the accompanying drawings and embodiments of the present invention:

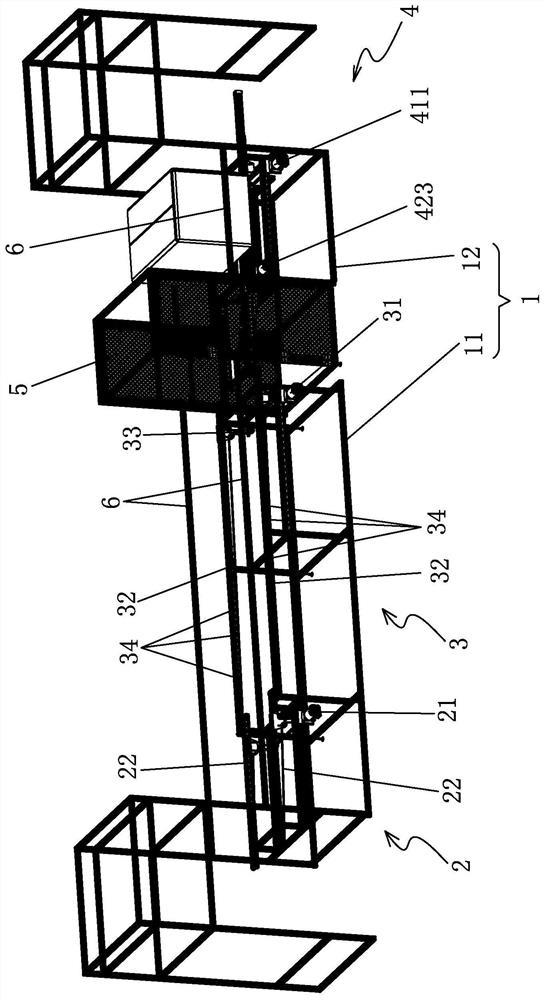

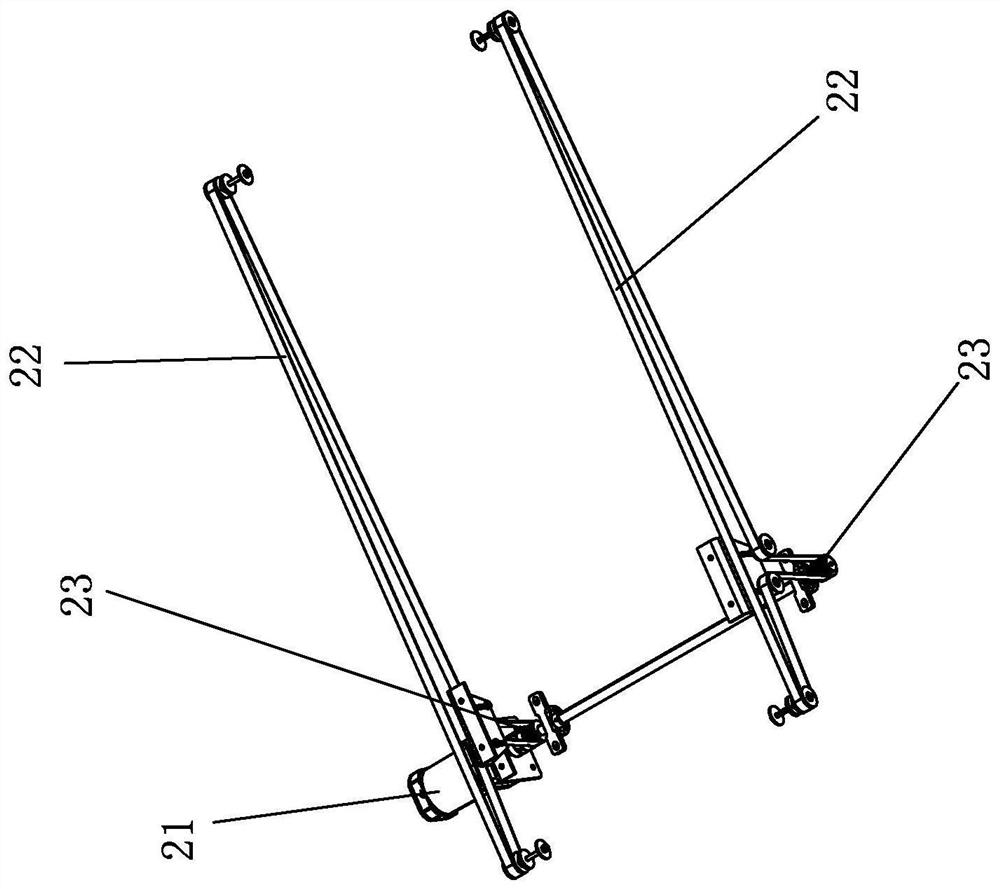

[0020] Such as Figure 1-5 As shown, a tobacco leaf outer box conveying device provided with a passage door includes a frame 1, and the frame 1 includes a front side frame 11 and a rear side frame 12, and the front side frame 11 and the rear side frame 12 There is a passage door 5 between them, the front side frame 11 is provided with the front side conveying device 2 and the middle part conveying device 3 which are connected with the outer box extracting device for conveying the outer box of tobacco leaves, and the rear side frame 12 is provided with the outer box and the outer box. The backside conveying device 4 that case lid closing device is connected, the rear side conveying device 4 comprises the rear side fixed conveying device 41 that is arranged on the rear side frame 12, and can retract into the rear side frame 12 or stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com