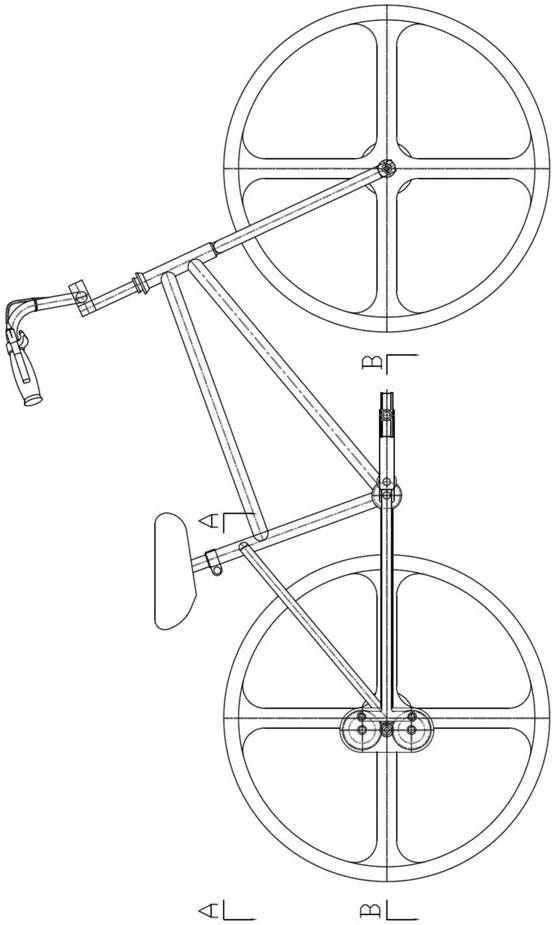

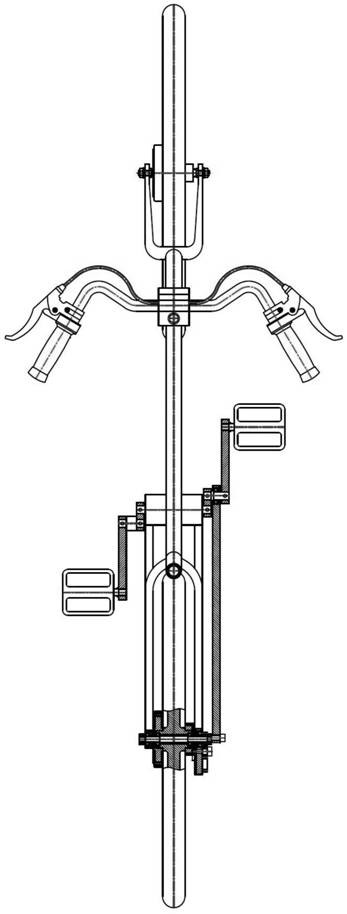

Bicycle gear rocker transmission mechanism

A transmission mechanism and bicycle technology, which is applied to wheel transmissions, vehicle components, vehicle gearboxes, etc., can solve problems such as low transmission efficiency, and achieve the effects of small power loss, high transmission efficiency, and smooth rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

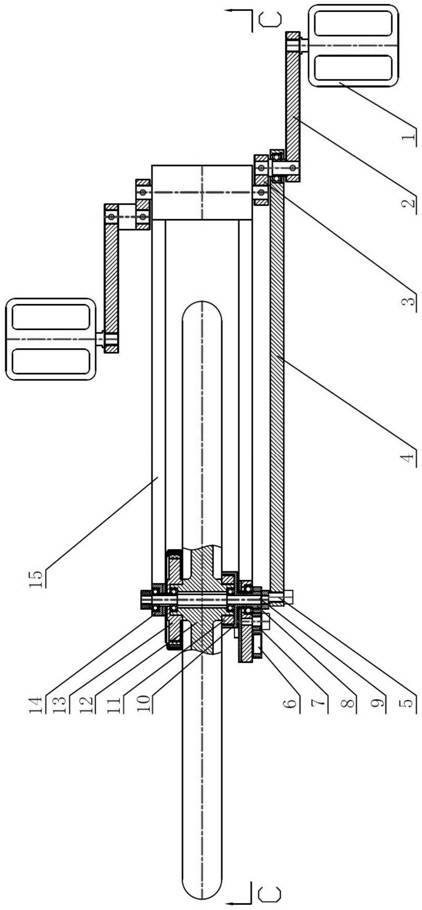

[0017] 1. The power transmission process of the gear rocker transmission mechanism in sequence:

[0018] exist image 3 Middle: Pedal (1) → Pedal lever (2) → Pedal rotation short connecting rod (3) → Transmission rocker (4) → Large gear rotation pin (5) → Speed up large gear (6) → Reverse Pinion (7) → Forward rotation pinion (8) → Flywheel outer ring flange (10) → One-way live flywheel (11) → Rear wheel hub (12)

[0019] In the process of power transmission, the power drives the pedal rod (2) to rotate through the pedal (1), and the pedal rod (2) is tightly connected with the pedal rotating short connecting rod (3), thus driving the pedal to rotate the short connecting rod (3) Rotate so that the transmission rocker (4) rotates along the pedals to rotate the short connecting rod (3) to rotate in parallel to the center of rotation, thereby driving the two large gears to rotate the pins (5) to rotate the two speed-up large gears in the same direction ( 6) The center rotates t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com