A towing traction device and traction method for an intelligent inspection robot

A traction device, intelligent inspection technology, applied in railway couplings, transportation and packaging, railway vehicle coupling accessories, etc. load, improve passability, and overcome limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

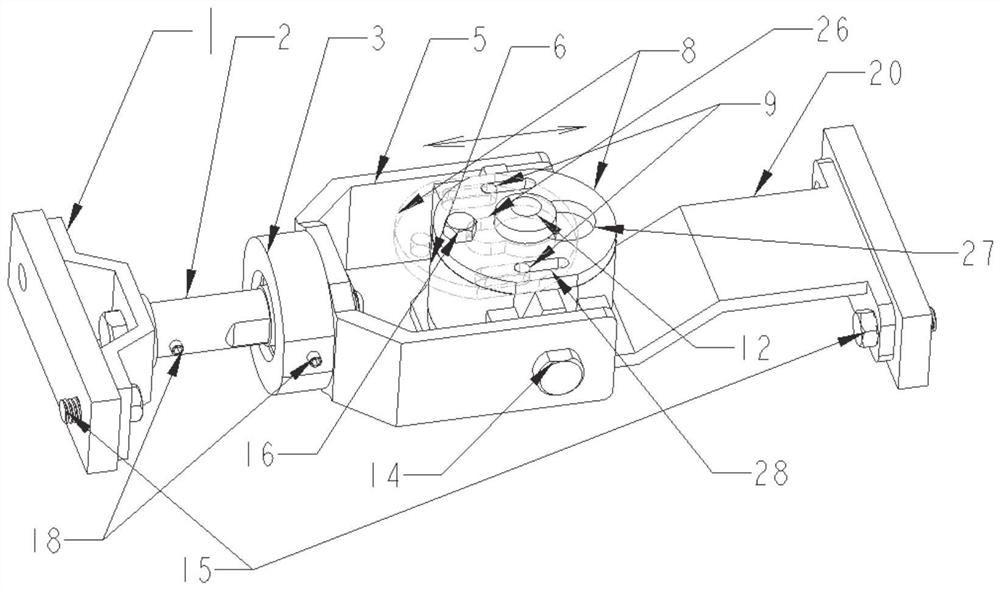

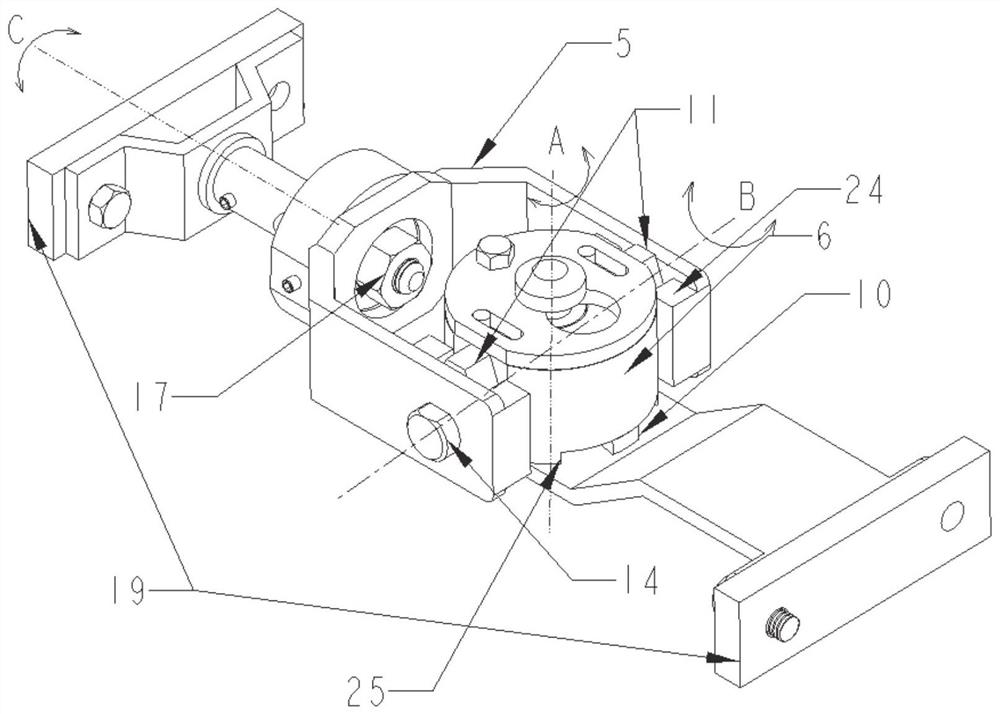

[0031] like figure 1 As shown in the figure, this embodiment provides a trailer traction device for an intelligent inspection robot, which includes: a mounting frame, a connecting rod, a traction fork, a traction shaft sleeve, a traction shaft and a traction bracket that are connected in sequence, and one end of the traction fork is connected to the The rod is connected in rotation, and the other end is hinged with the traction shaft sleeve; the traction shaft is installed in the traction shaft sleeve, and one end of the traction shaft is connected with the traction bracket.

[0032] Further, a connecting rod is installed on the mounting frame, the traction fork is a U-shaped structure, and the bottom of the U-shaped structure has a first mounting hole, which is rotatably connected with the connecting rod of the mounting frame through the first mounting hole; more specifically, The connecting rod is rotatably connected to the traction fork through a double-row angular contact ...

Embodiment 2

[0045] The present disclosure also provides an intelligent inspection robot, which includes the trailer traction device as described in the above embodiments, and the traction operation is performed by the trailer traction device.

Embodiment 3

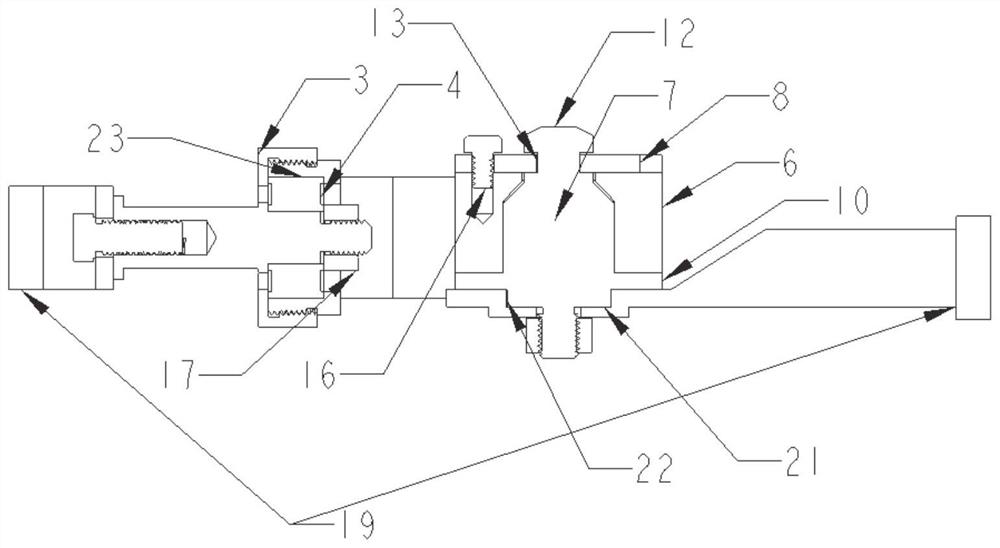

[0047] This embodiment also provides a towing method for a towed traction device of an intelligent inspection robot, including:

[0048] Install the mounting bracket on the traction device, and connect one end of the traction bracket with the object to be towed;

[0049] The traction device drags the mounting frame to move, and the mounting frame transmits the traction force to the traction fork;

[0050] The traction fork adjusts the angle with the traction force and transmits the traction force to the traction bushing;

[0051] The traction bush adjusts the angle with the traction force and transmits the traction force to the traction shaft;

[0052] The traction shaft adjusts the angle with the traction force and transmits the traction force to the traction bracket;

[0053] The traction bracket drives the object to be pulled to move.

[0054] Specifically, when the main vehicle body needs to pull the trailer body forward or backward, the main vehicle body drags the moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com