Automobile accessory welding fixture

A technology for welding tooling and auto parts, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of reducing welding efficiency, affecting users' use, and large adjustment range of welding nodes, so as to improve work efficiency , easy operation, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

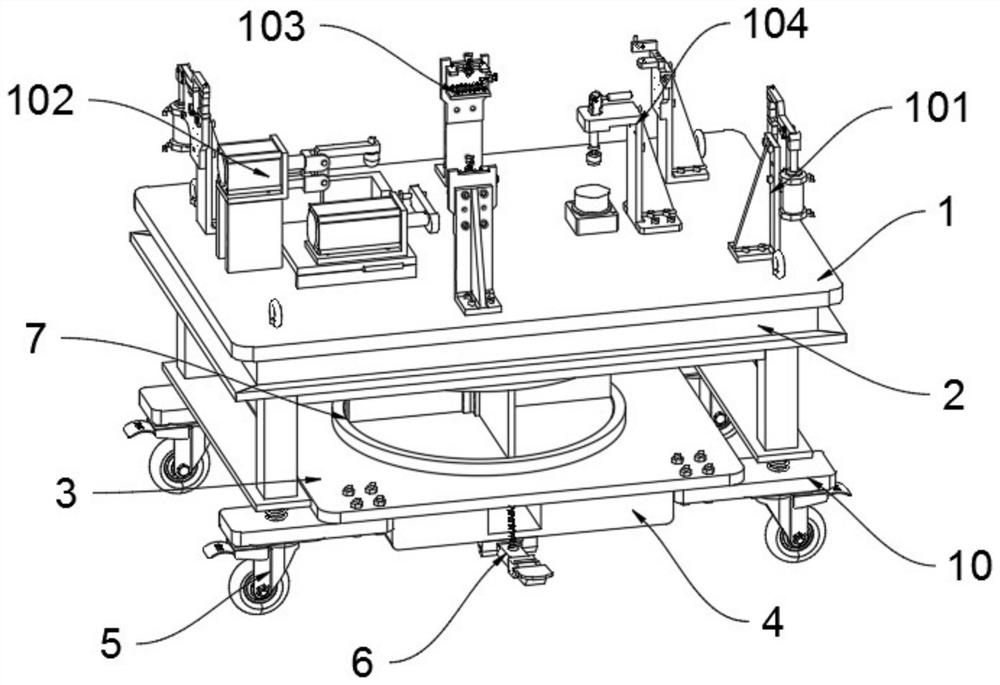

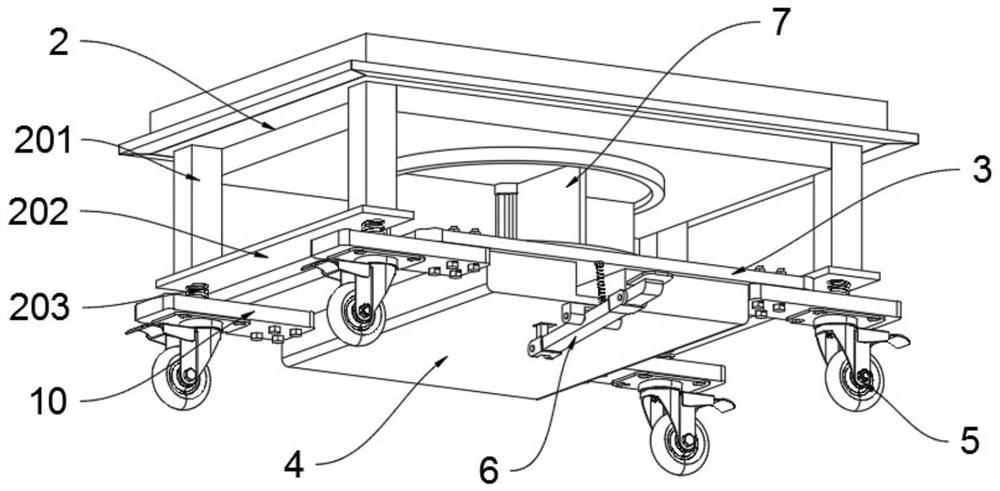

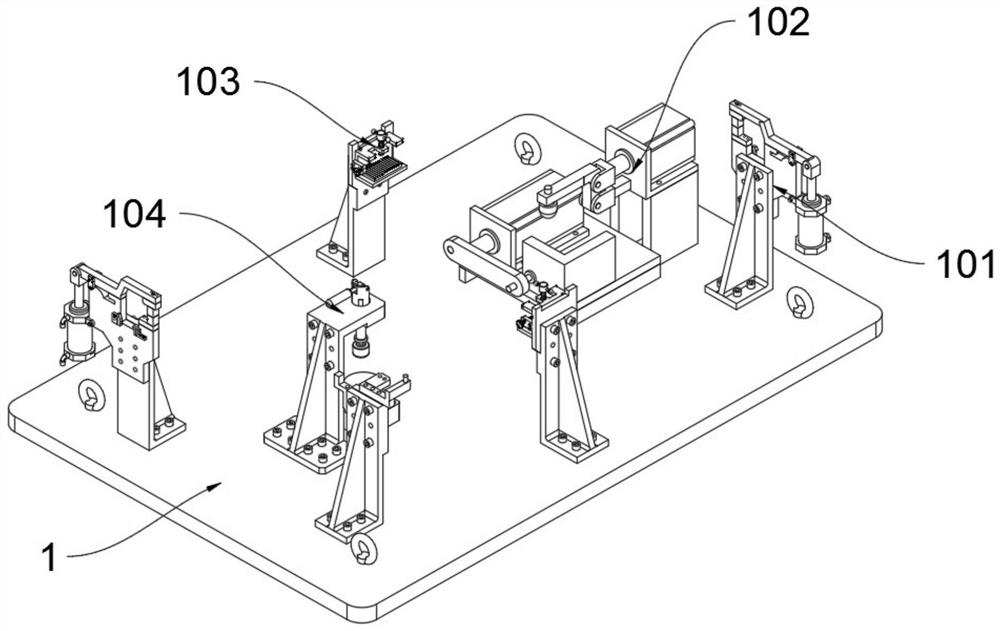

[0035] as attached figure 1 to attach Figure 8 Shown:

[0036] The invention provides a welding tool for auto parts, comprising a welding platform 1, a base 2 is provided at the bottom of the welding platform 1, and the base 2 is fixedly connected with the welding platform 1 through bolts; the welding platform 1 includes a first cylinder fixing clamp 101, a second Cylinder fixing clips 102, adjusting clips 103 and spring fixing clips 104, first cylinder fixing clips 101 are arranged at two opposite corners on the top of welding platform 1, second cylinder fixing clips 102 are arranged on the left side of welding platform 1 top, welding platform 1 top Adjusting clips 103 are provided on the front and rear sides, and spring fixing clips 104 are provided at the middle of the top of the welding platform 1; a tool box 7 is provided at the bottom of the base 2; Support rods 201 are welded at four diagonal positions at the bottom, and backing plates 202 are welded to the bottom en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com