Deuterated benzene catalytic reaction kettle with continuous catalytic function and working method thereof

A catalytic reaction, deuterated benzene technology, applied in the direction of chemical instruments and methods, chemical/physical processes, etc., can solve problems such as the inability to meet the needs of responsible processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

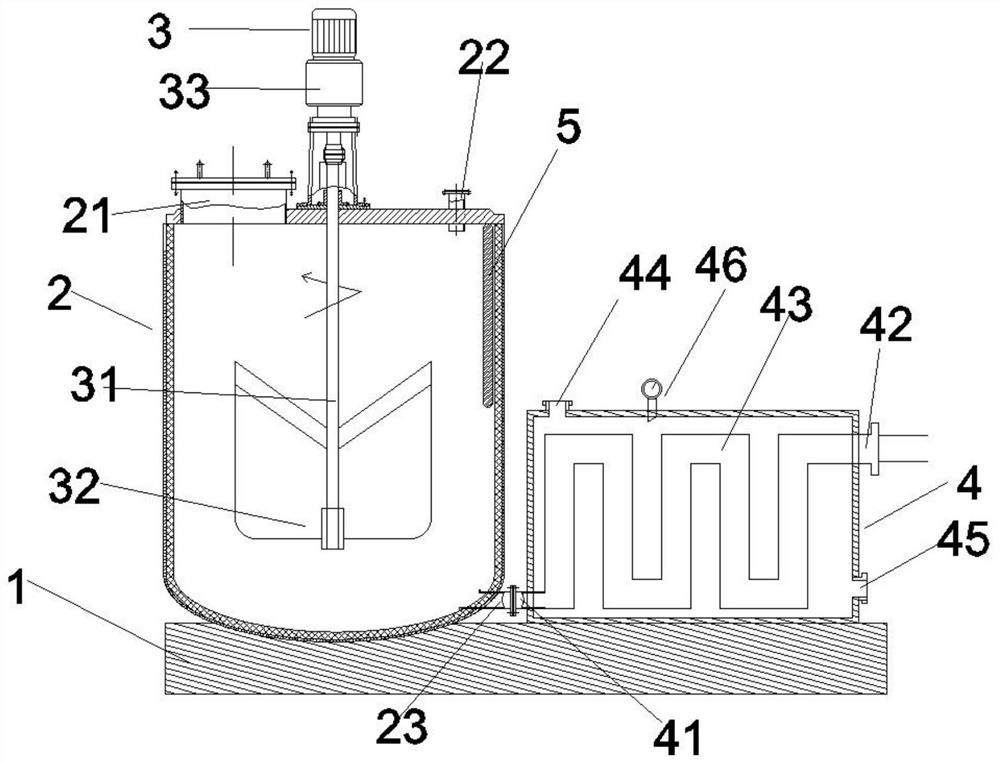

[0026] like figure 1 The shown deuterated benzene catalytic reactor with continuous catalytic function includes a base 1 , a mixing tank 2 , a discharge port 23 , a stirring motor 3 , a stirring shaft 31 , a stirring part 32 , a heat exchange box 4 and a liquid inlet 41 . Wherein, the mixing kettle 2 is arranged on one end of the base 1 , and the heat exchange box 4 is arranged on the base 1 and is located at one end close to the mixing kettle 2 . The stirring motor 3 is arranged on the mixing kettle 2 and is located in the middle of the top of the mixing kettle 2 . The stirring shaft 31 is arranged in the mixing kettle 2 , and one end is connected with the stirring motor 3 . The stirring part 32 is disposed on the end of the stirring shaft 31 away from the stirring motor 3 . The stirring part 32 is a plate-shaped stirring piece. The discharge port 23 is located at the bottom of the mixing tank 2 and is located at one end close to the heat exchange box 4 . The liquid inlet...

Embodiment 2

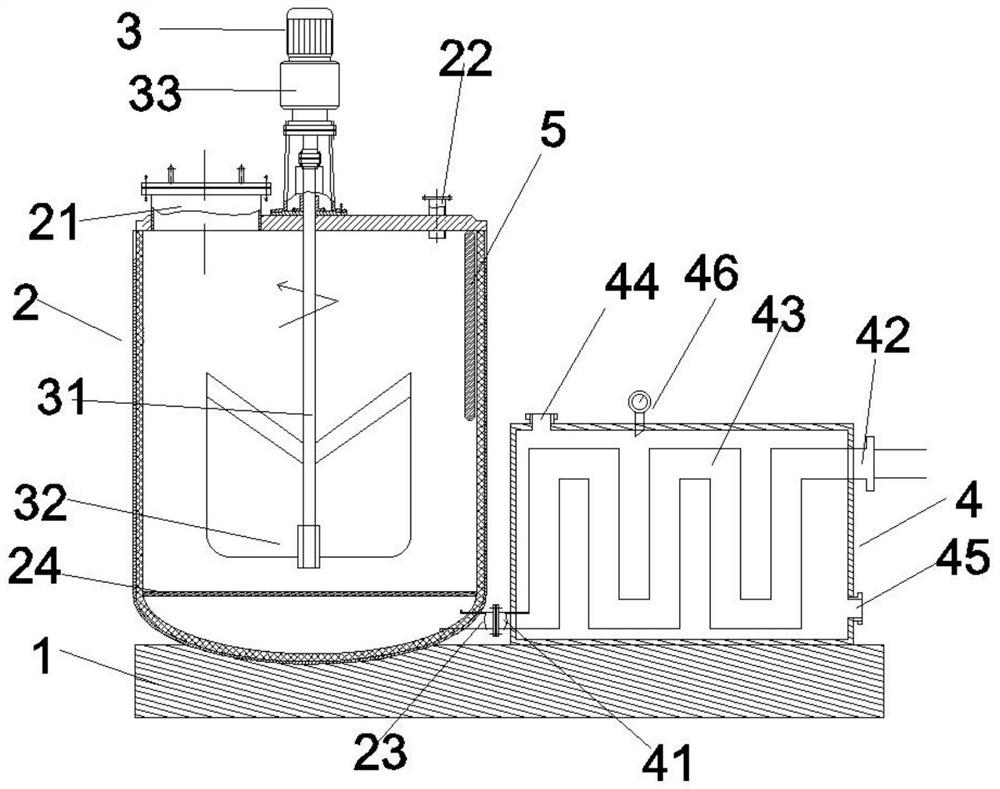

[0035] like figure 2The shown deuterated benzene catalytic reactor with continuous catalytic function includes a base 1 , a mixing tank 2 , a discharge port 23 , a stirring motor 3 , a stirring shaft 31 , a stirring part 32 , a heat exchange box 4 and a liquid inlet 41 . Wherein, the mixing kettle 2 is arranged on one end of the base 1 , and the heat exchange box 4 is arranged on the base 1 and is located at one end close to the mixing kettle 2 . The stirring motor 3 is arranged on the mixing kettle 2 and is located in the middle of the top of the mixing kettle 2 . The stirring shaft 31 is arranged in the mixing kettle 2 , and one end is connected with the stirring motor 3 . The stirring part 32 is disposed on the end of the stirring shaft 31 away from the stirring motor 3 . The stirring part 32 is a plate-shaped stirring piece. The discharge port 23 is located at the bottom of the mixing tank 2 and is located at one end close to the heat exchange box 4 . The liquid inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com