Textile equipment for down jacket processing

A technology for textile equipment and down jackets, which is applied in the field of textile equipment for down jacket processing. It can solve the problems of cumbersome operation, filling and breaking of down jackets, loss, etc., and achieve the effects of simplifying the operation process, preventing random floating, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

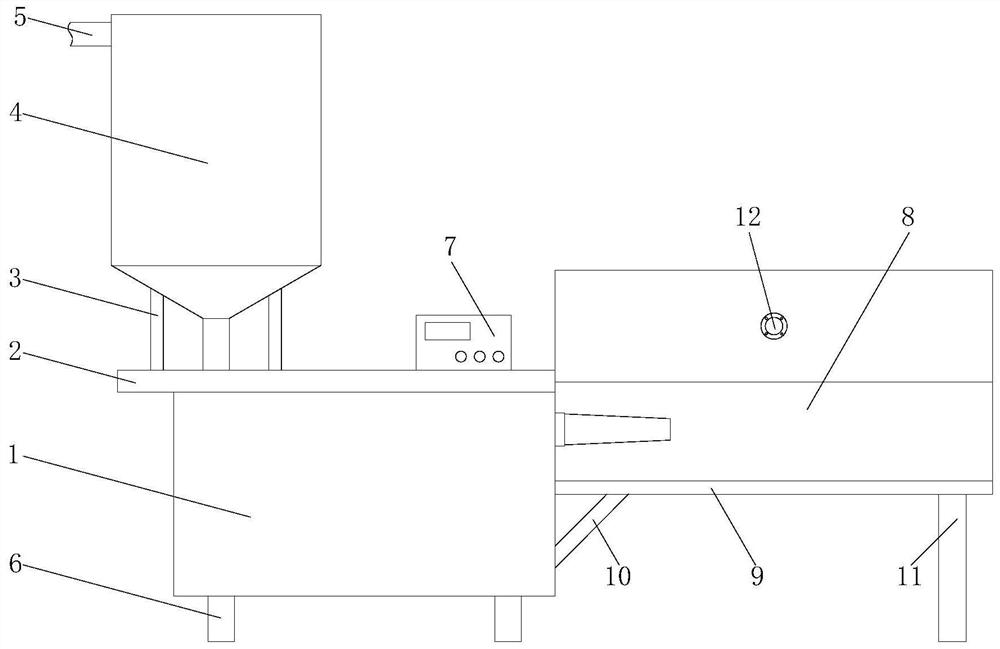

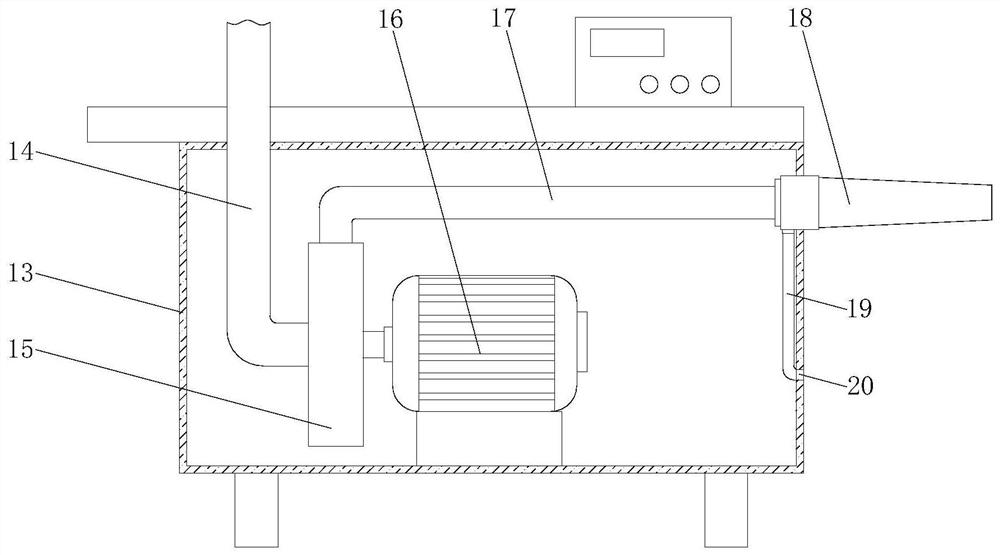

[0033] Such as Figure 1-5 As shown, the present invention provides a kind of technical scheme:

[0034] A textile equipment for down jacket processing, comprising a table top 2, an equipment cabinet 1 is arranged on the bottom of the table top 2, and foot pads 6 are fixedly installed on the bottom of the equipment cabinet 1, the number of foot pads 6 is four, and the four foot pads 6 They are all made of rubber with shock-absorbing properties. Using the foot pad 6 with shock-absorbing function can effectively reduce the vibration generated when the equipment is running. A control panel 7 is fixedly installed on the right side of the upper surface of the table top 2. The control panel 7 is set, the control switch of the drive motor 16 and the exhaust fan 26 is integrated on the control panel 7, and the operation of the drive motor 16 and the exhaust fan 26 is controlled by the button provided on the control panel 7, so that the drive motor 16 and the exhaust fan 26 One-button...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com