Anti-seismic ladder-type cable bridge for nuclear island of nuclear power station

A cable tray, anti-vibration technology, applied in electrical components, springs/shock absorbers, vibration suppression adjustment and other directions, can solve the problems of high connection looseness hidden danger, long installation time of ladder type tray, low construction efficiency, etc., and achieve assembly efficiency. High, the hidden danger of bolt loosening is reduced, and the effect of avoiding axial stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

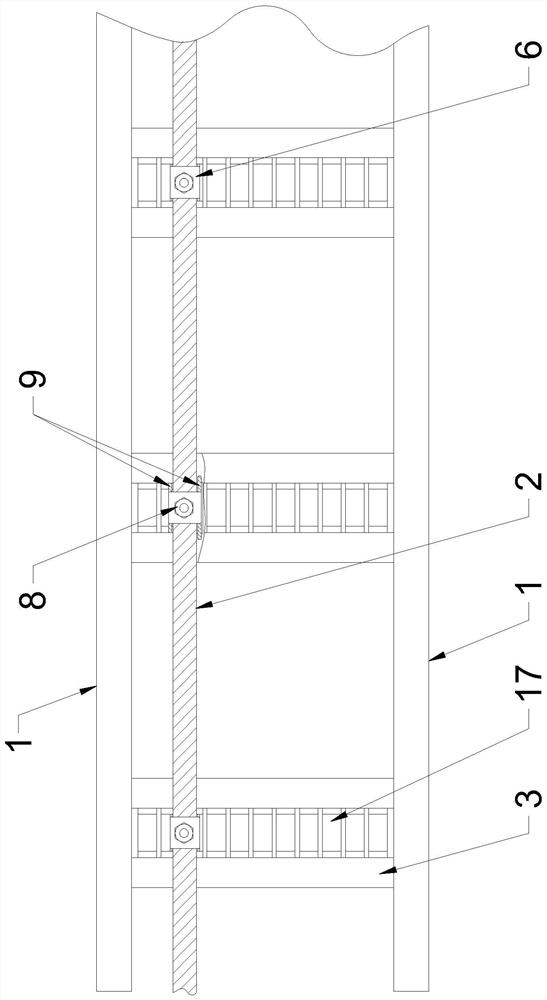

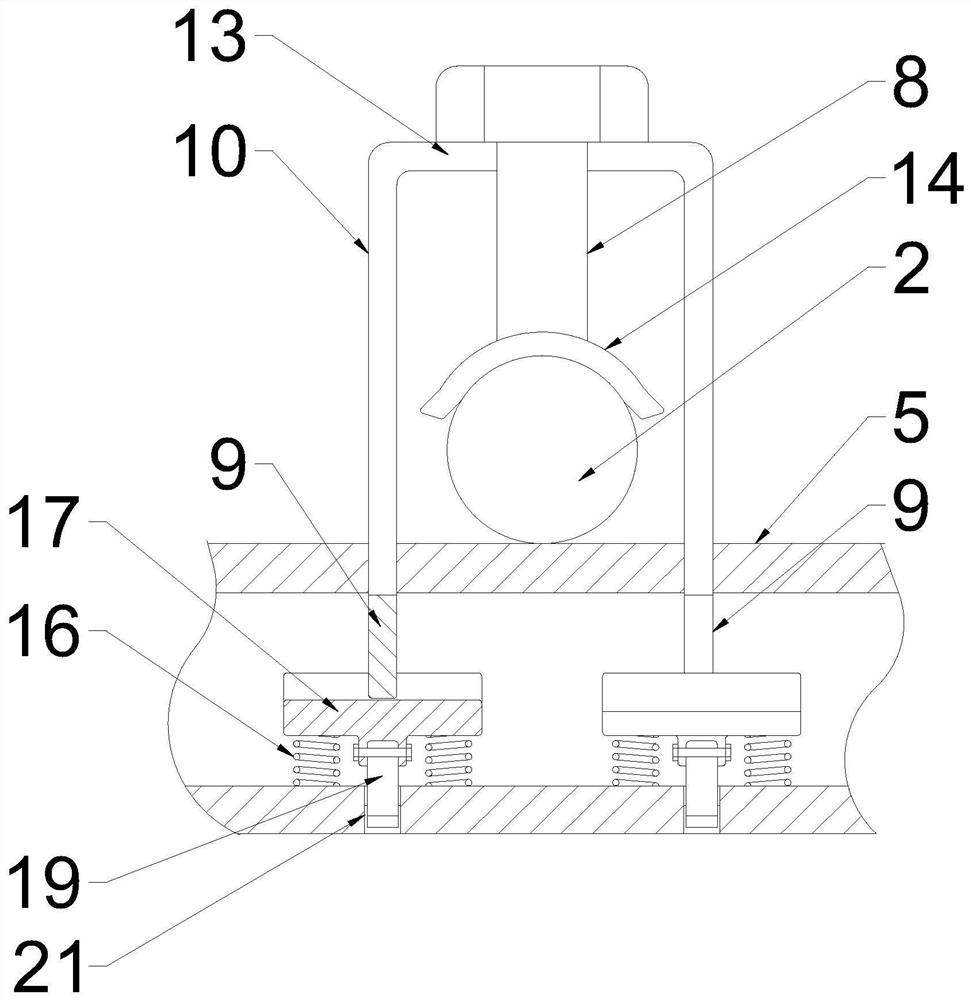

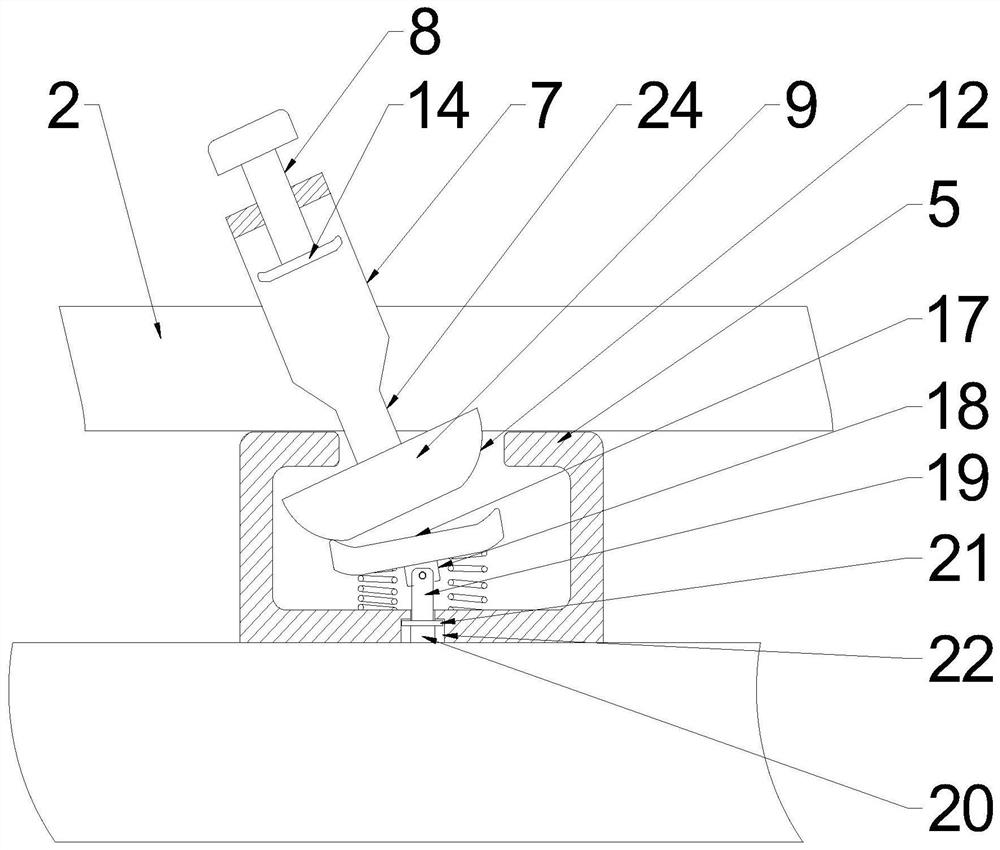

[0025] Such as Figure 1 to Figure 4 As shown, the anti-seismic ladder type cable tray for a nuclear island in a nuclear power plant includes two side frames 1 and a plurality of ladder plates 3 installed on the side frames 1 for supporting cables 2 . The ladder plate 3 is cut from C-shaped steel. The C-shaped steel used in this bridge frame has a steel channel 4 with an open top, and the left and right sides of the top of the steel channel 4 have inwardly bent top flanges 5 . A pressing piece 6 is installed on the ladder plate 3, and the pressing piece 6 compresses the cable 2 on the ladder plate 3. Specifically, the pressing piece 6 includes a pressing plate 7, a locking bolt 8 and a top plate 9, two of the pressing plate 7 Pressing legs 10 are erected on the front and rear sides of cable 2, and two top sheets 9 are respectively connected to the bottoms of the two pressing legs 10, and top sheet 9 can be set as a structure integrally formed with the pressing plate to facilit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com