Transformer low-voltage bushing drainage wire clamp

A technology of low-voltage bushings and drain clamps, applied in the direction of transformers/inductor coils/windings/connections, etc., can solve the problems of easy damage, infirmity, inconvenient use, etc., and achieve large clamping force, good conductivity, The effect of improving the flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

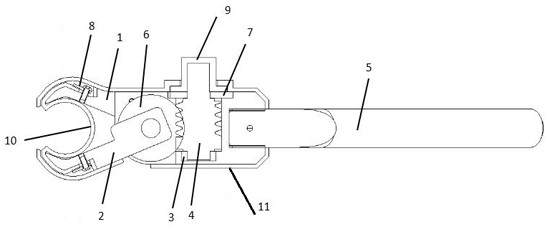

[0016] The transformer low-voltage bushing drainage clamp provided by this embodiment is composed of such as figure 1 The main body of the device shown is a transformer low-voltage bushing drainage clamp, including a main clamp 1 and a secondary clamp 2. The gill of the main clamp 1 is provided with a worm wheel 6 and a worm 4 that are matched by gears. The worm wheel 6 is provided with Square groove, sub-clamp 2 is installed on the square groove, the bottom of worm 4 is fixed by bushing 3, the top of worm 4 is fixed by fixed cover 7, the part of worm 4 protruding from main clamp 1 is covered by insulating cover 9, main clamp 1 and Conductive braiding is fixed between the auxiliary clips 2 through the conductive tape pressure plate 8, the conductive tape pressure plate 8 is installed in the jaws of the main clip 1 and the secondary clip 2, and the surface of the main clip 1 and the secondary clip 2 is covered with an insulating plate 11, The bottom of the main clamp 1 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com