A device and method for producing hydrogen by electrolyzing water

A hydrogen production device and electrolyzed water technology, applied in the direction of electrolysis components, electrolysis process, steam engine device, etc., can solve the problems of low conversion efficiency and high cost of hydrogen production, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

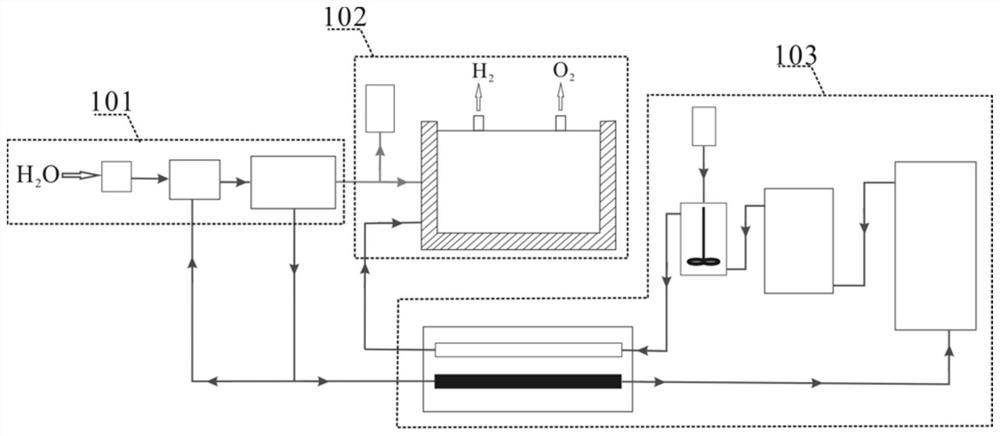

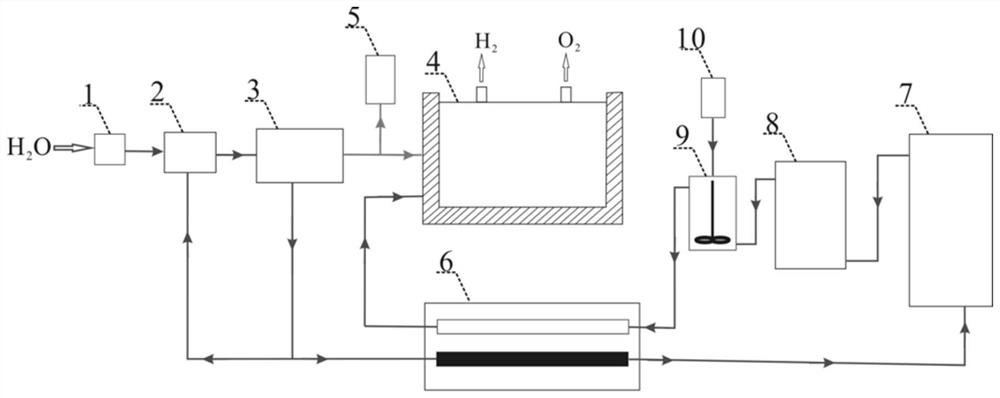

[0054] This embodiment provides a hydrogen production device by electrolyzing water, and its structural schematic diagram is as follows Figure 1-Figure 2 shown, from Figure 1-Figure 2 As can be seen, the device consists of:

[0055] Power generation system 101, hot water recycling system 103 and electrolysis water hydrogen production system 102;

[0056] The power generation system 101 includes a water tank 1, a steam generator 2 and a steam turbine generator 3; the water tank 1 is connected to the steam turbine generator 3 through a pipeline through the steam generator 2;

[0057] The electrolyzed water hydrogen production system 102 includes an insulated electrolyzer 4; the insulated electrolyzer 4 is electrically connected to the turbo generator 3;

[0058] The hot water recycling system 103 includes a heat exchanger 6, a water storage tank 7, a filter 8, a mixing tank 9 and a solvent storage tank 10; the liquid outlet of the turbo generator 3 passes through a pipeline ...

Embodiment 2

[0063] This embodiment provides a method for producing hydrogen by electrolyzing water, wherein the method for producing hydrogen by electrolyzing water uses the device for producing hydrogen by electrolyzing water provided in Example 1, and the method includes the following specific steps:

[0064] First inject pure water into the water tank 1 for storage, then inject water into the steam generator 2, the steam generated by the steam generator enters the turbo generator 3 through the pipeline, and the electric energy generated by power generation is transmitted to the heat preservation electrolytic tank 4 for electrolysis of water The energy required for producing hydrogen is stored in the energy storage battery 5 for backup; when the power generation system 101 is insufficient or overhauled, the energy storage battery 5 is used to supply power to the heat preservation electrolyzer 4, and the electrolyzed water is used for hydrogen production;

[0065] The water vapor after th...

Embodiment 3

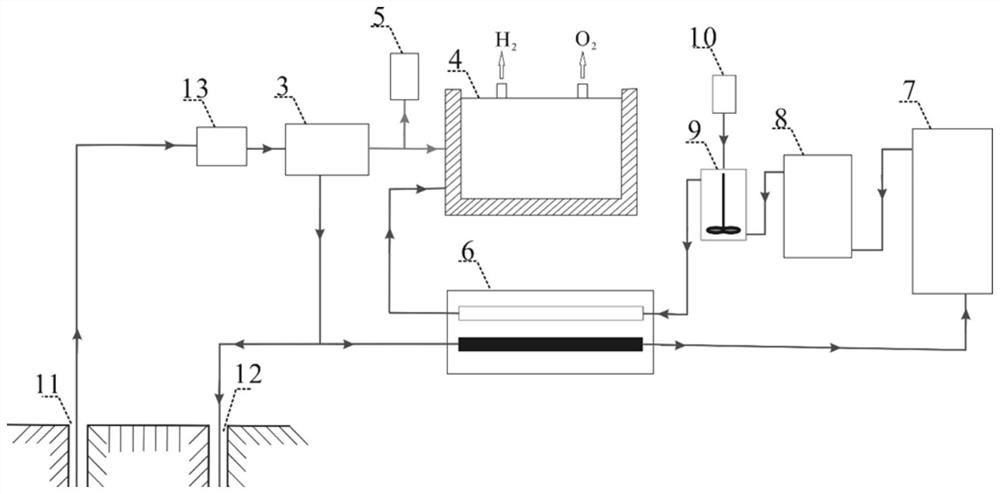

[0071] This embodiment provides a hydrogen production device by electrolysis of water (the device uses geothermal water as a water source), and its structural diagram is as follows image 3 shown, from image 3 As can be seen, the device consists of:

[0072] Power generation system, hot water recycling system and electrolysis water hydrogen production system;

[0073] The power generation system includes a preprocessor 13 and a turbogenerator 3; the preprocessor 13 is connected to the turbogenerator 3 through a pipeline;

[0074] The electrolyzed water hydrogen production system includes an insulated electrolyzer 4; the insulated electrolyzer 4 is electrically connected to the turbo generator 3;

[0075] The hot water recycling system includes a heat exchanger 6, a water storage tank 7, a filter 8, a mixing tank 9 and a solvent storage tank 10; The inlet of water bucket 7 links to each other, and the outlet of this storage bucket 7 links to each other through the inlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com