Rapid welding device for new-energy lithium battery pack

A lithium battery pack, rapid welding technology, applied in welding equipment, resistance welding equipment, welding/welding/cutting items, etc., can solve the problem of time-consuming and laborious, and achieve the effect of improving work efficiency and realizing automatic feeding and feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

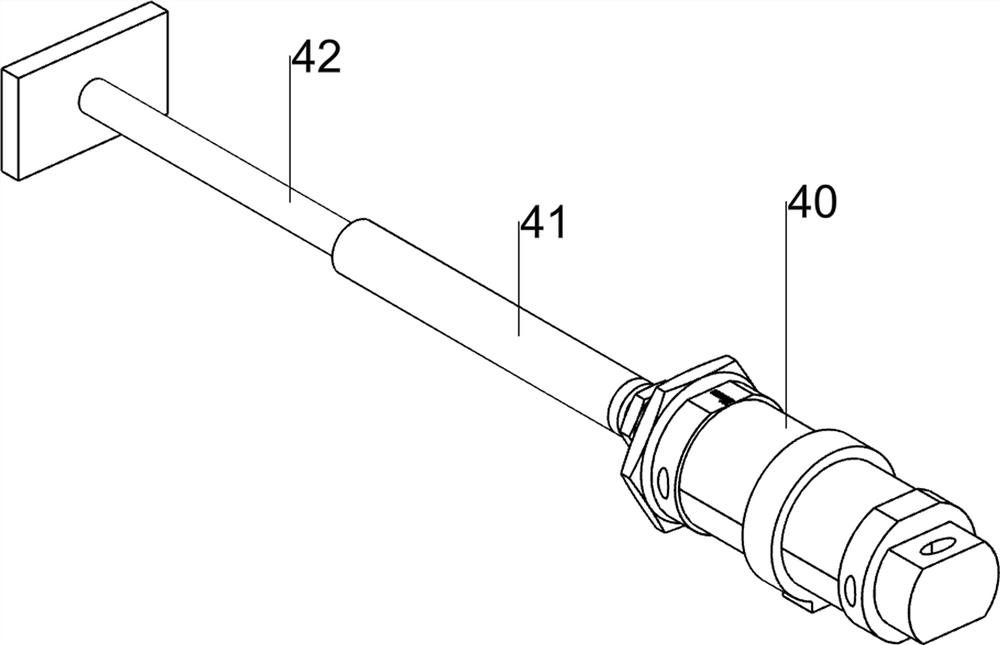

[0065] A fast welding device for a new energy lithium battery pack, such as figure 1 As shown, it includes a base 1, a mounting plate 2, an electric welding mechanism 3 and a pushing mechanism 4, the left side of the base 1 is provided with a mounting plate 2, the left side of the base 1 is provided with an electric welding mechanism 3, and the right side of the base 1 is provided with a pushing mechanism 4.

[0066] When people need to weld the battery, the battery is first placed on the mounting plate 2, and then the pushing mechanism 4 is controlled so that the parts of the pushing mechanism 4 move the battery to the left, and then the iron sheet is placed between the tops of the batteries, Then start the parts of the electric welding mechanism 3, and press the parts of the electric welding mechanism 3 to move down, so that the parts of the piezoelectric welding mechanism 3 weld the battery. After completion, control the pushing mechanism 4, so that the parts of the pushing...

Embodiment 2

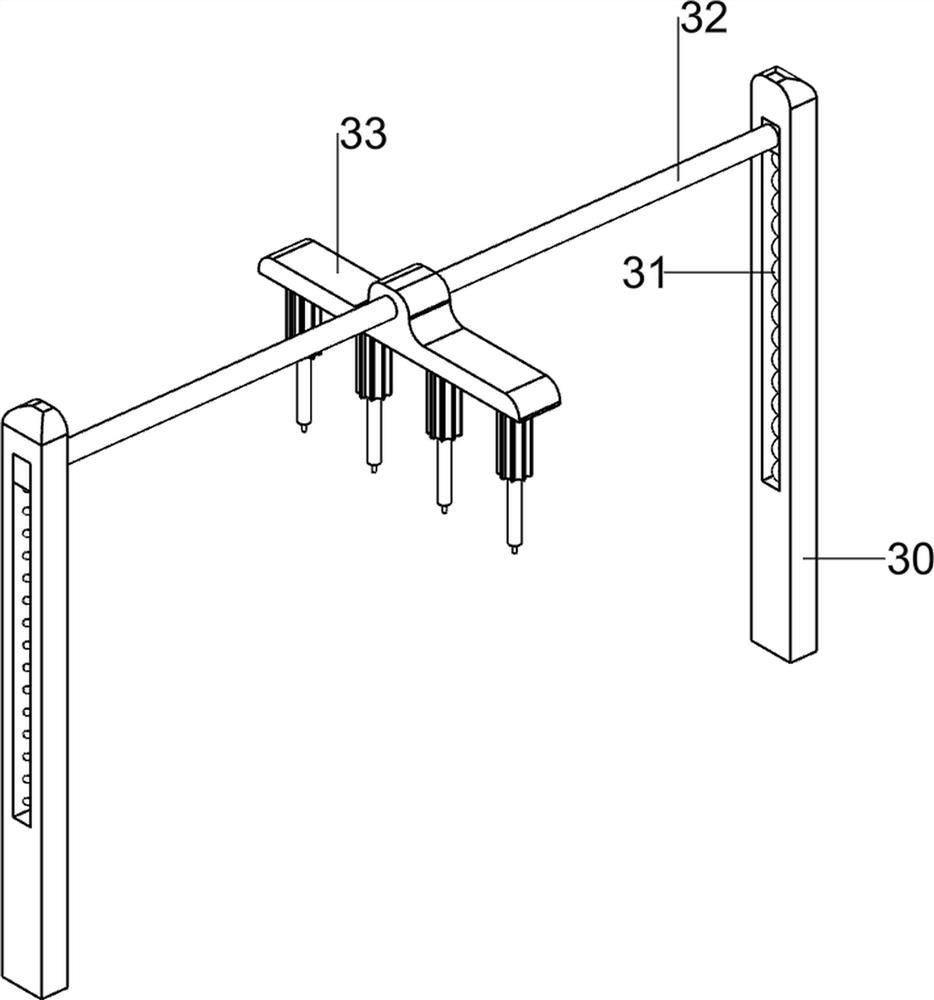

[0068] On the basis of Example 1, such as Figure 2-4 As shown, the electric welding mechanism 3 includes a first slide rail 30, a first spring 31, a lifting rod 32 and a spot welder 33, and the front and rear sides of the left part of the base 1 are connected with the first slide rail 30, between the first slide rail 30 There is a lifting rod 32 slidingly connected between them, and a first spring 31 is connected between the front and rear sides of the bottom of the lifting rod 32 and the inner bottom wall of the first slide rail 30 , and a spot welder 33 is arranged in the middle of the lifting rod 32 .

[0069]When people need to weld the battery, start the spot welder 33, press the lifting lever 32, drive the spot welder 33 to move down and weld the battery, the first spring 31 is compressed, let go after completion, and the first spring 31 Under the action, drive the lifting rod 32 and the spot welder 33 to move upwards and reset, and close the spot welder 33 to get final...

Embodiment 3

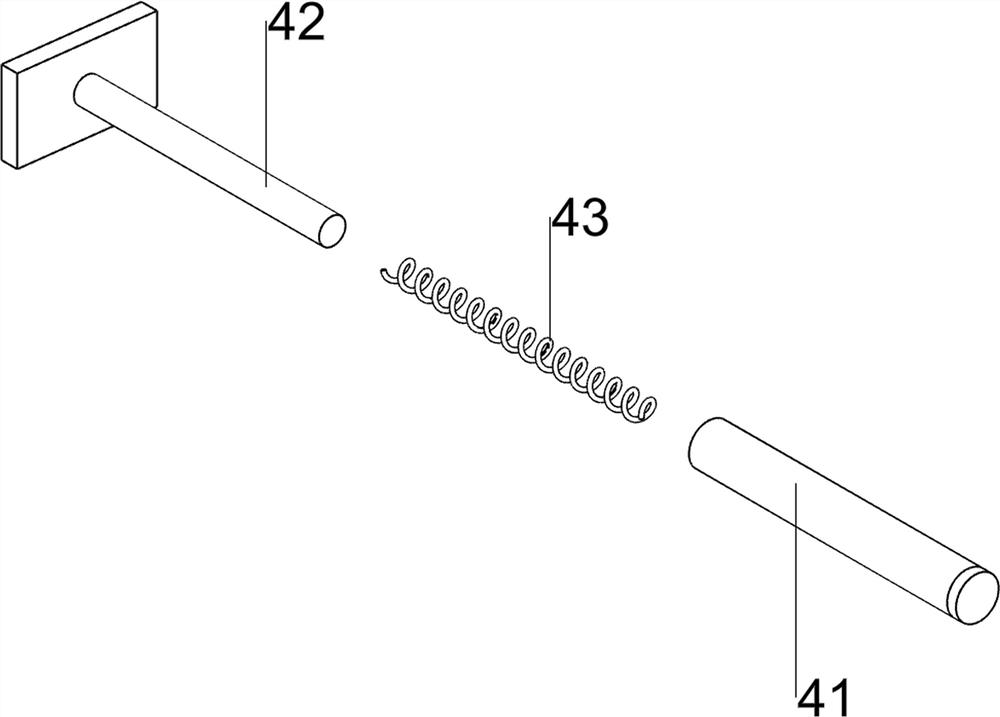

[0073] On the basis of Example 2, such as Figure 5-9 As shown, a limit mechanism 5 is also included, and the limit mechanism 5 includes a first connecting rod 50, an extrusion block 51, a limiter 52, a wedge block 53, a mounting block 54, a first fixed rod 55 and a third spring 56 , the front and rear sides of the hollow cylinder 41 are connected with first connecting rods 50, the first connecting rods 50 are provided with extruding blocks 51, and the left and right sides of the base 1 are connected with mounting blocks 54, and the mounting blocks 54 are all slidably connected. There is a first fixed rod 55, the inside of the first fixed rod 55 is provided with a stopper 52, the stopper 52 is slidably connected with the mounting plate 2, and the right side of the stopper 52 is provided with a wedge block 53, and the first fixed rod 55 A third spring 56 is provided between the outer side and the mounting block 54 on the same side, and the third spring 56 is sleeved on the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com