Cosmetic bottle capable of shaking for pressurization

A cosmetic bottle and internal pressure technology, which is applied in the packaging of cosmetics, cosmetic powder containers, dressing containers, etc., can solve problems such as sore fingers, emotional instability, and high pressing pressure, so as to reduce strength, reduce pressing times, The effect of solving waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

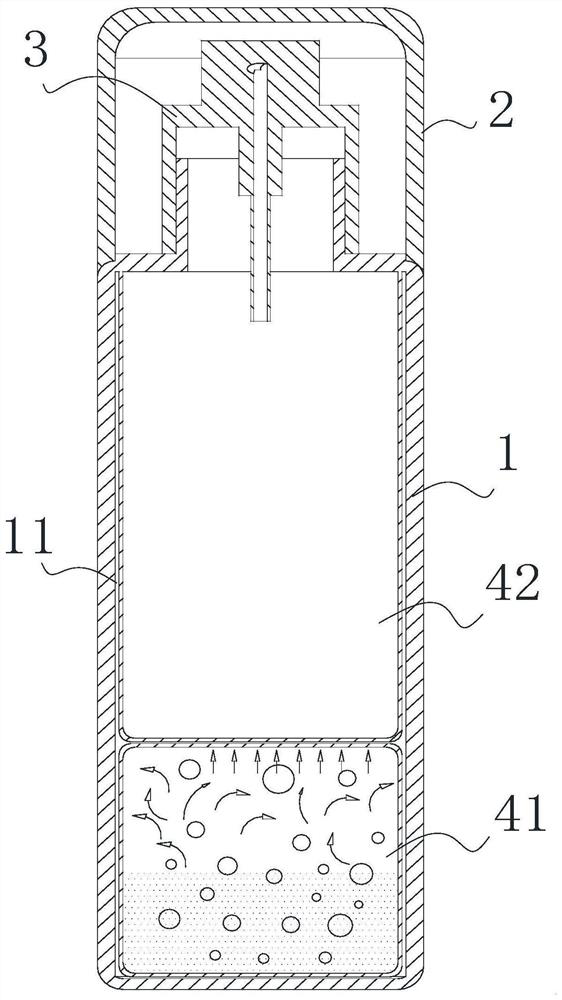

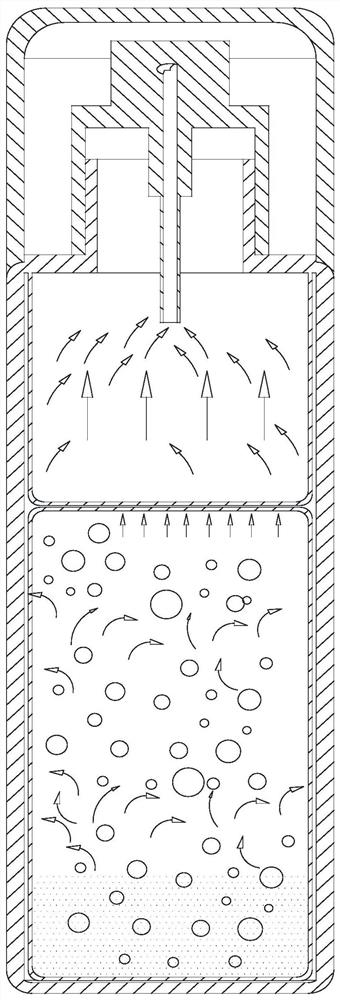

[0030] Such as Figure 1-2 As shown, a cosmetic bottle that can be shaken and pressurized includes a cosmetic bottle 1, a bottle cap 2 that is fastened by an annular boss on the upper surface of the cosmetic bottle 1, and a spray head 3 that is screwed to the upper port of the cosmetic bottle 1. Wherein, the cosmetic bottle 1 is made of rigid material, and the cosmetic bottle 1 is provided with an accommodating cavity 11 . A first liner 41 and a second liner 42 are placed in the cavity 11, the second liner 42 is located above the first liner 41, the upper part of the second liner 42 is connected to the upper side of the inner wall of the cavity 11, the first The liner 41 is a sealed body. Both the first liner 41 and the second liner 42 are made of materials with certain flexibility. Or it is elastic, it can expand when the force is applied, and it will return to the original state when the force disappears. It can also be a rebound structure with stretching. In this scheme...

Embodiment 2

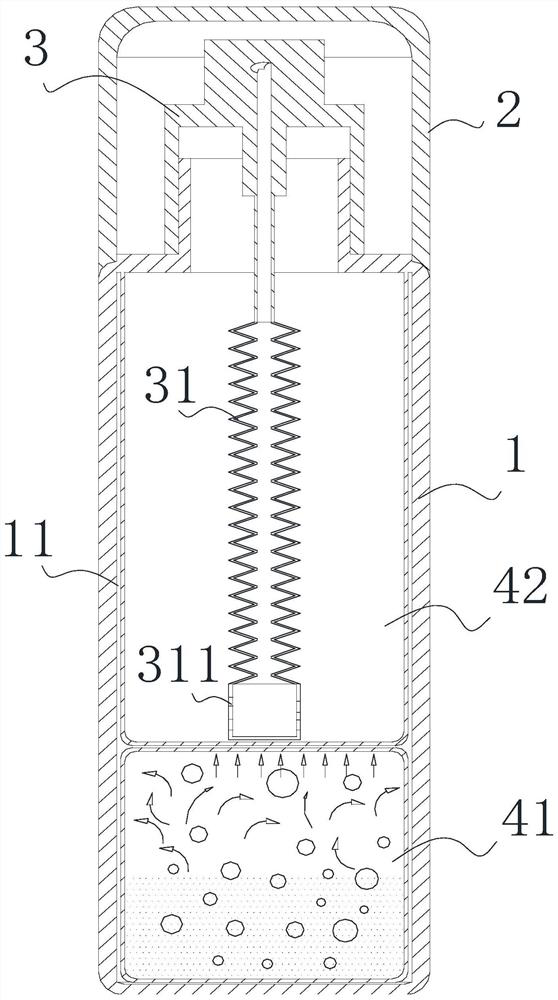

[0035] On the basis of Embodiment 1, a cosmetic bottle that can be shaken and pressurized has added a liquid pipe 31 at the bottom of the spray head 3, wherein the liquid pipe 31 is a bellows, the upper end of the liquid pipe 31 is connected to the bottom of the spray head 3, and the lower end is connected to the bottom of the spray head 3. The lower part of the second inner container 42 fits inside, and a plurality of through holes 311 are opened on the side wall of the lower end where the liquid pipe 31 contacts the second inner container 42, and the cosmetics in the second inner container 42 are sucked through the through holes 311. The liquid pipe 31 then enters the nozzle 3 for atomization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com