A three-phase transformer with extractable pressing plate

A three-phase transformer, pull-out technology, applied in the field of three-phase transformers, can solve the problems of labor-consuming, cumbersome operation process, danger, etc., and achieve the effect of labor-saving and simple replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

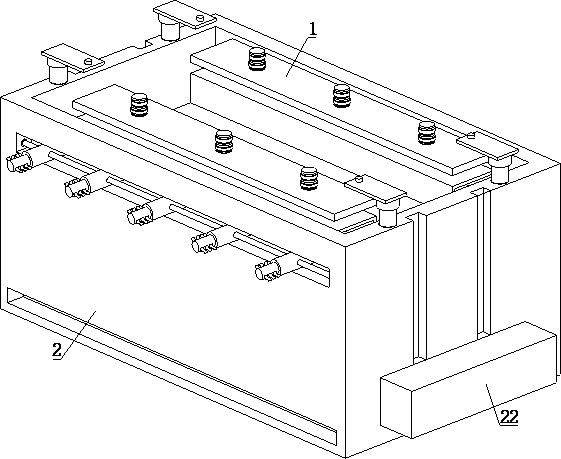

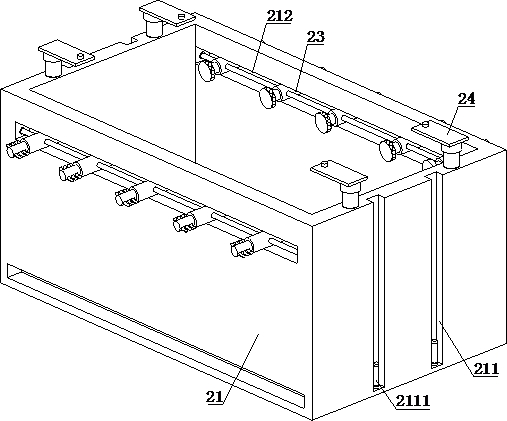

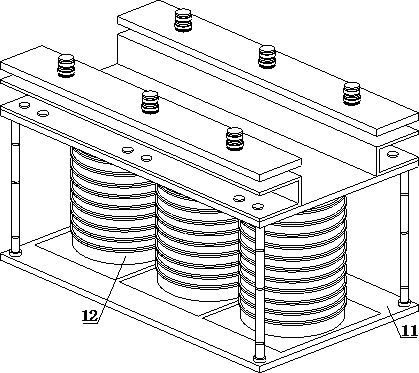

[0031] refer to figure 1 ,3 , 4 and 5, a three-phase transformer with extractable pressure plate, including a main body 1 and an outsourcing mechanism 2, the main body 1 is arranged inside the outsourcing mechanism 2, the main body 1 includes a frame mechanism 11 and a power mechanism 12, the power mechanism 12 Set inside the frame mechanism 11, the power mechanism 12 includes an electric coil winding 121, a bottom plate 122 and an end plate 123, one end of the electric coil winding 121 is provided with a bottom plate 122, and the other end of the electric coil winding 121 is provided with an end plate 123, and the electric coil The winding 121 is connected to the frame mechanism 11 through the bottom plate 122 and the end plate 123. The frame mechanism 11 includes a main lifting rod 111, a pressing plate A112 and a pressing plate B113. One end of the main lifting rod 111 is provided with a pressing plate A112, and the other end of the main lifting rod 111 is provided with Wit...

Embodiment 2

[0036] refer to figure 1 , 3 , 4 and 5, a three-phase transformer with extractable pressure plate, including a main body 1 and an outsourcing mechanism 2, the main body 1 is arranged inside the outsourcing mechanism 2, the main body 1 includes a frame mechanism 11 and a power mechanism 12, the power mechanism 12 Set inside the frame mechanism 11, the power mechanism 12 includes an electric coil winding 121, a bottom plate 122 and an end plate 123, one end of the electric coil winding 121 is provided with a bottom plate 122, and the other end of the electric coil winding 121 is provided with an end plate 123, and the electric coil The winding 121 is connected to the frame mechanism 11 through the bottom plate 122 and the end plate 123. The frame mechanism 11 includes a main lifting rod 111, a pressing plate A112 and a pressing plate B113. One end of the main lifting rod 111 is provided with a pressing plate A112, and the other end of the main lifting rod 111 is provided with W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com