Liquid discharging and gas production integrated method after low-pressure water-bearing reservoir fracturing reconstruction

A gas production and reservoir technology, which is applied in the field of integration of liquid drainage and gas production after fracturing of low-pressure water-bearing reservoirs, can solve problems such as low formation pressure, insufficient energy, and inability to produce oil and gas by blowing through, with less difficulty in achieving , the effect of short technical cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

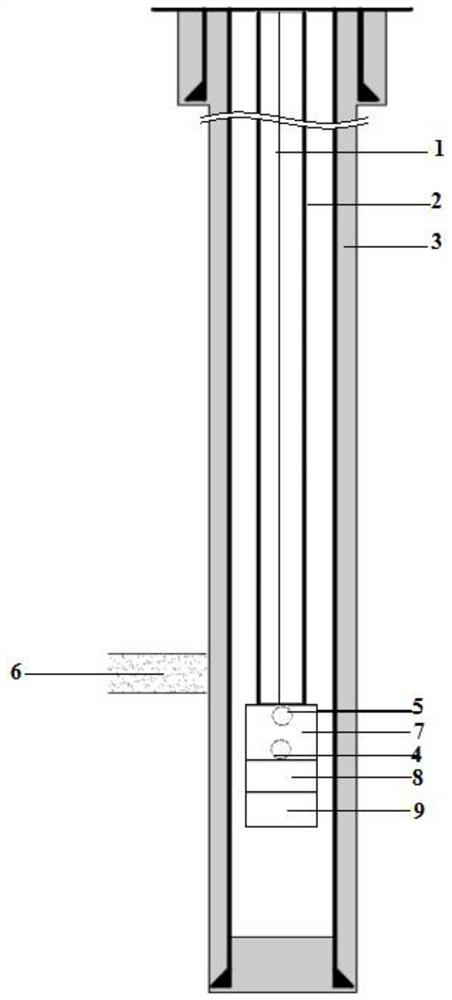

[0023] like figure 1 As shown in the figure, an integrated method for liquid drainage and gas production after fracturing of a low-pressure water-bearing reservoir, comprising the following steps: 1) after the completion of fracturing and fracturing of a gas well, run a coiled tubing drainage pipe into the tubing or casing wellbore The column string is drained;

[0024] 2) When the bottom-hole liquid level in the tubing drops below the perforation section, the fluid in the tubing stops draining and gas production starts; when the bottom-hole liquid level in the tubing rises to the set height, gas production is stopped, and the gas production is continued. The oil pipe drain string is drained again, and the above step 2) is repeated until the liquid drain is completed in the oil pipe, so as to realize the integration of liquid drain and gas production in the oil pipe;

[0025] 3) When the liquid drainage in the casing is completed, firstly pull out the coiled tubing drainage s...

Embodiment 2

[0029] On the basis of Example 1, further, the coiled tubing drainage string includes a cable 1, a coiled tubing 2 and an automatic start-stop pump. The cable 1 is located inside the coiled tubing 2, and the lower end of the cable 1 is connected to the automatic start-stop pump. After the fracturing of the gas well is completed, run the coiled tubing drainage string in the tubing or casing 3 wellbore to drain the liquid. When the liquid level rises to the liquid level that needs to be drained, the pump will automatically start and stop to drain the liquid. The liquid is discharged to the ground through the coiled tubing 2. When the liquid level drops below the liquid level that needs to be discharged, the pump will automatically start and stop. After the liquid discharge is completed, gas production starts, which realizes continuous intelligent drainage and gas production of water-bearing reservoirs, with a high degree of automation. , shorten the drainage cycle, and reduce the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com