Fixed bed bioreactor

A technology of bioreactor and fixed bed, which is applied in the direction of specific-purpose bioreactor/fermenter, combination of bioreactor/fermenter, method of supporting/immobilizing microorganisms, etc., which can solve the problem of insufficient mixing and insufficient absorption of cells Nutrients, slow cell growth and other issues, to achieve the effect of full absorption, increase the concentration of cell culture, and avoid inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

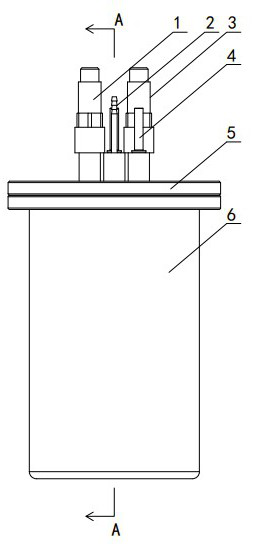

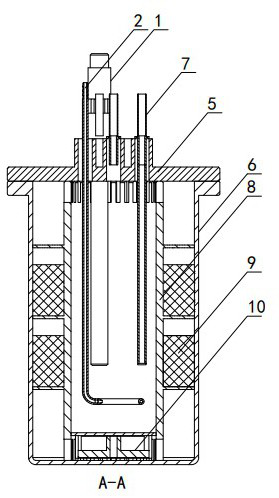

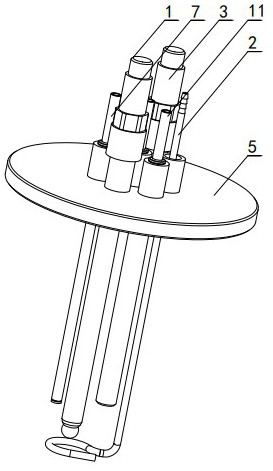

[0028] Figure 1~8 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~8 The present invention will be further described.

[0029] Such as figure 1 As shown, a fixed bed bioreactor comprises a tank body 6 with an open upper end, a tank cover 5 is arranged at the upper port of the tank body 6, and a plurality of protruding tank cover 5 upper surfaces are provided on the tank cover 5 interface 12 (see Figure 4 ), refer to image 3 A dissolved oxygen detector 1, an air supply pipe 2, a pH detection pipe 3, an acid-base defoaming adding pipe 4, a sampling pipe 7 and a feeding pipe 11 are installed on the tank cover 5 through the interface 12, the dissolved oxygen detector 1, the replenishing pipe The top of the air pipe 2, the pH detection tube 3, the acid-base defoaming adding tube 4, the sampling tube 7 and the feeding tube 11 are located above the tank cover 5, and the lower end thereof passes through the tank cover 5 along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com