Adjustable 3D printing nozzle

A 3D printing and adjustable technology, applied in coating devices, additive processing, etc., can solve the problems of high cost, high maintenance cost, difficult maintenance, etc., to ensure circulating flow, improve cooling efficiency, and increase spraying materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

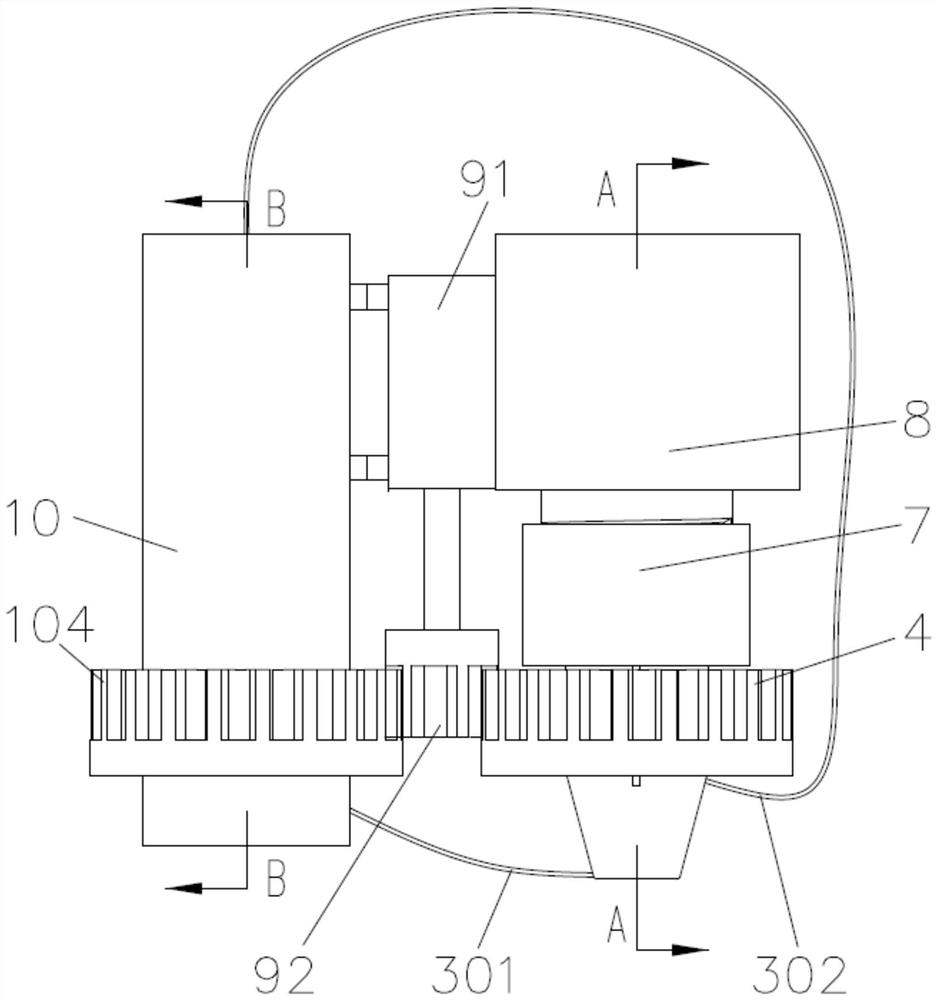

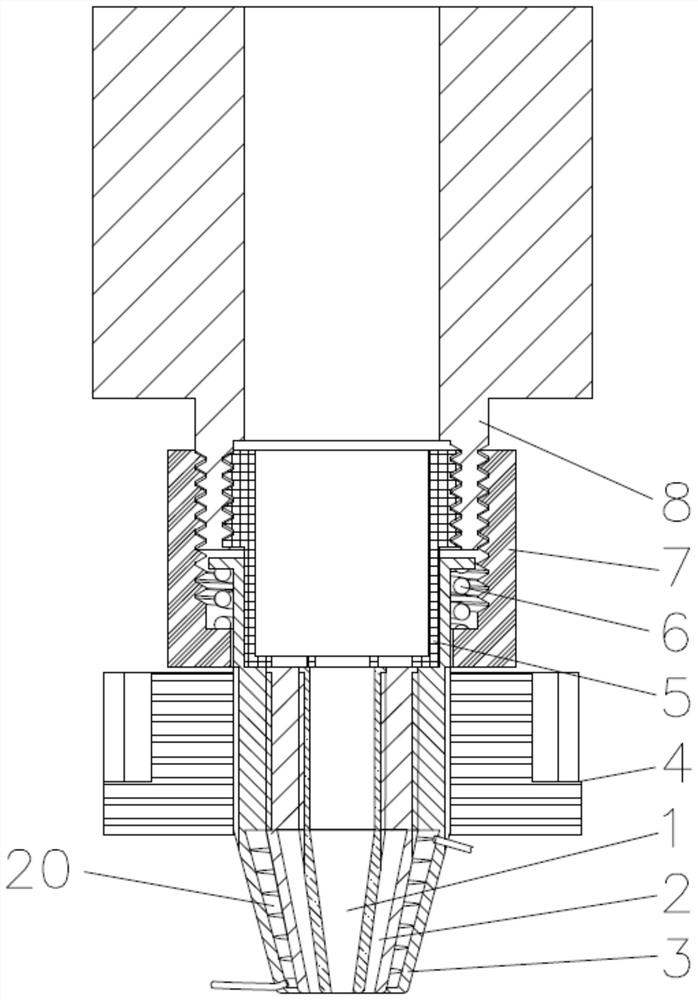

[0044] Such as Figure 1-11 As shown, an adjustable 3D printing nozzle is characterized in that: it includes a nozzle assembly, and the nozzle assembly includes a first nozzle 1, a second nozzle 2, a third nozzle 3, a driven gear 4, a blocking member 5, a spring 6, a fixed Part 7, feeding part 8 and drive assembly 9; wherein, the ends of the first nozzle 1, the second nozzle 2 and the third nozzle 3 are all tapered structures and the first nozzle 1 is installed inside the second nozzle 2, and the second nozzle 2 is installed inside the third nozzle 3, and the driven gear 4 is socketed outside the third nozzle 3;

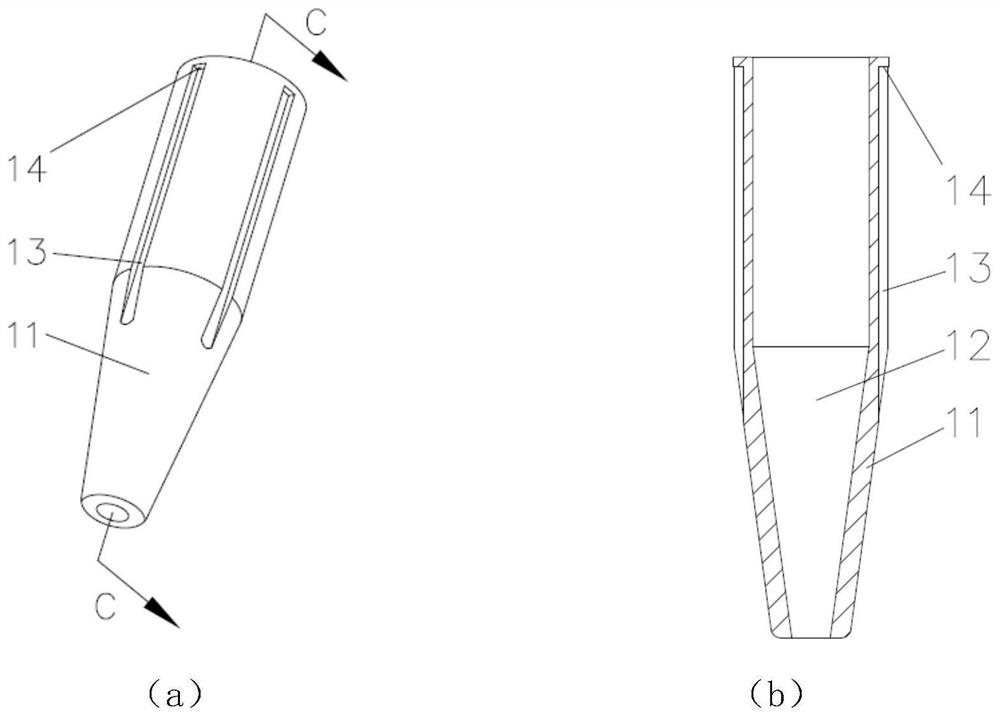

[0045] Specifically, the first spray head 1 includes a first spray head body 11, a first spray hole 12, a first installation groove 13, and a first outer stop shoulder 14. The first spray hole 12 runs through the interior of the first spray head body 11 and their centers The axes are collinear, the first installation grooves 13 are evenly distributed on the outer wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com