Skimming mud scraper

A kind of scraper and scraper technology, which is applied to sedimentation tanks, feeding/discharging devices of sedimentation tanks, chemical instruments and methods, etc., which can solve the problems of unclean scraping and insufficient scraping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

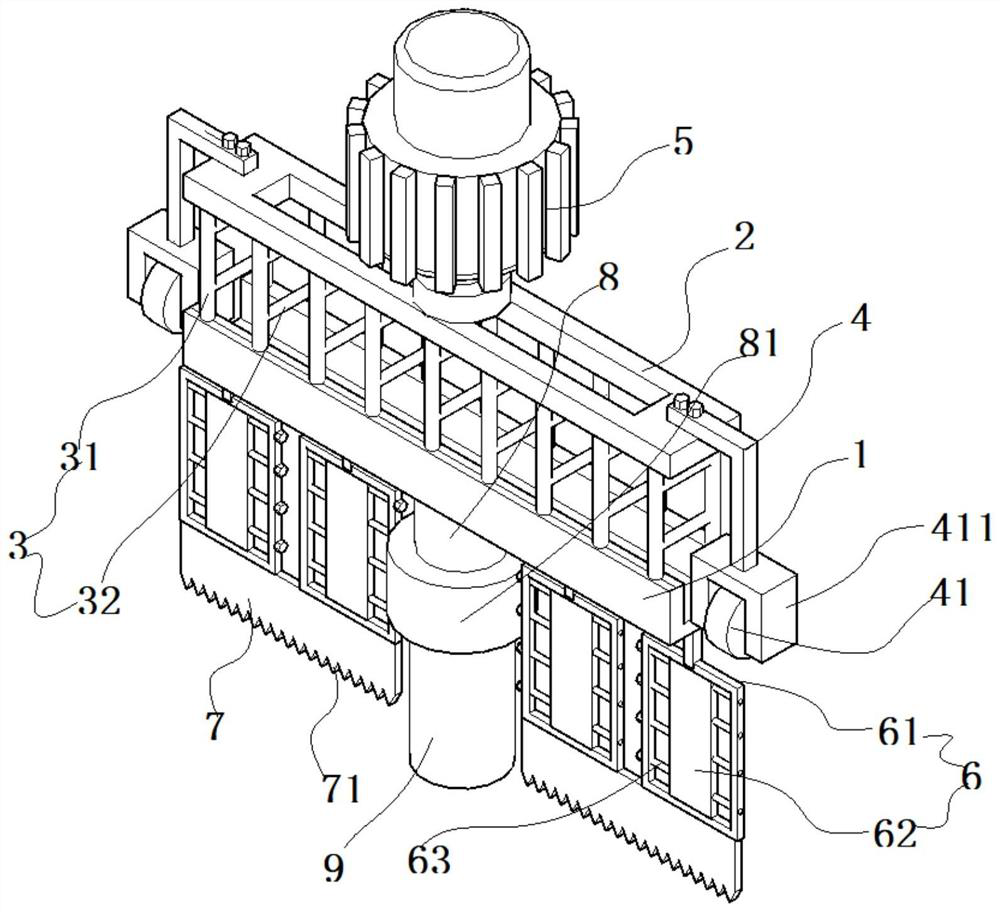

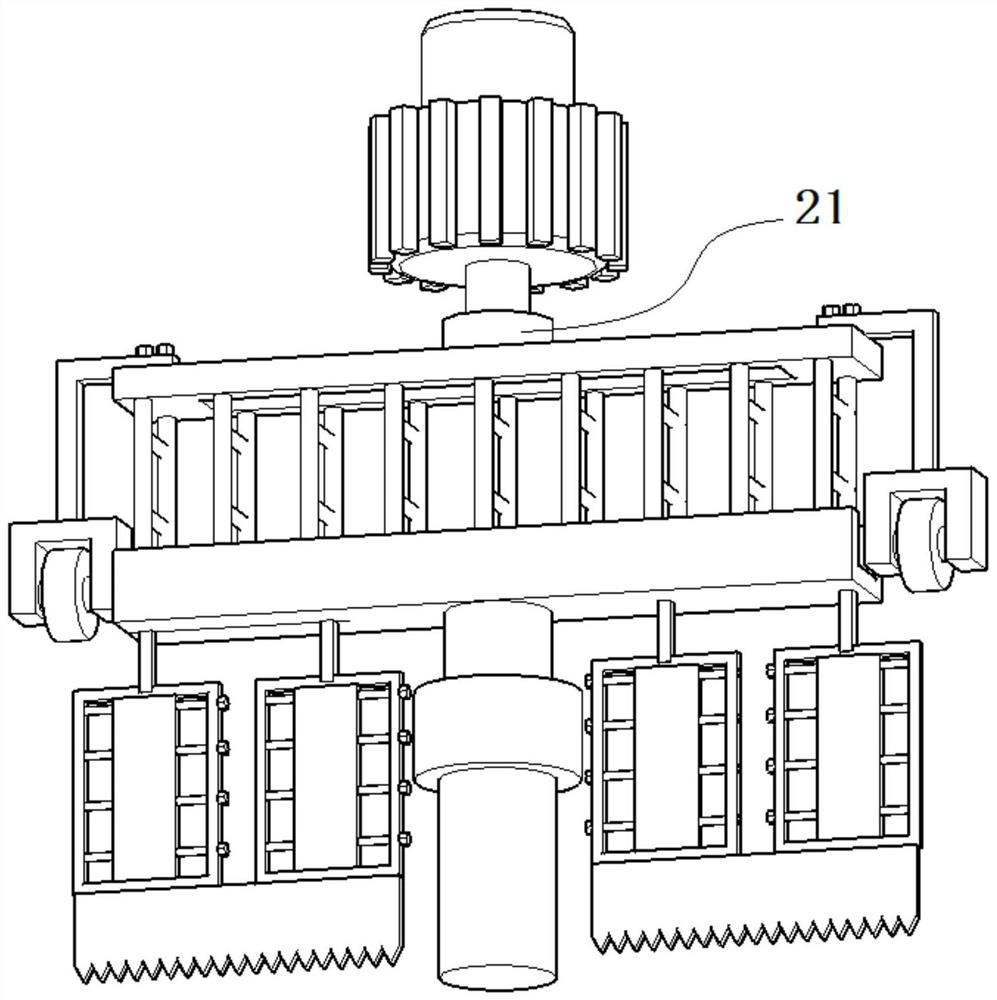

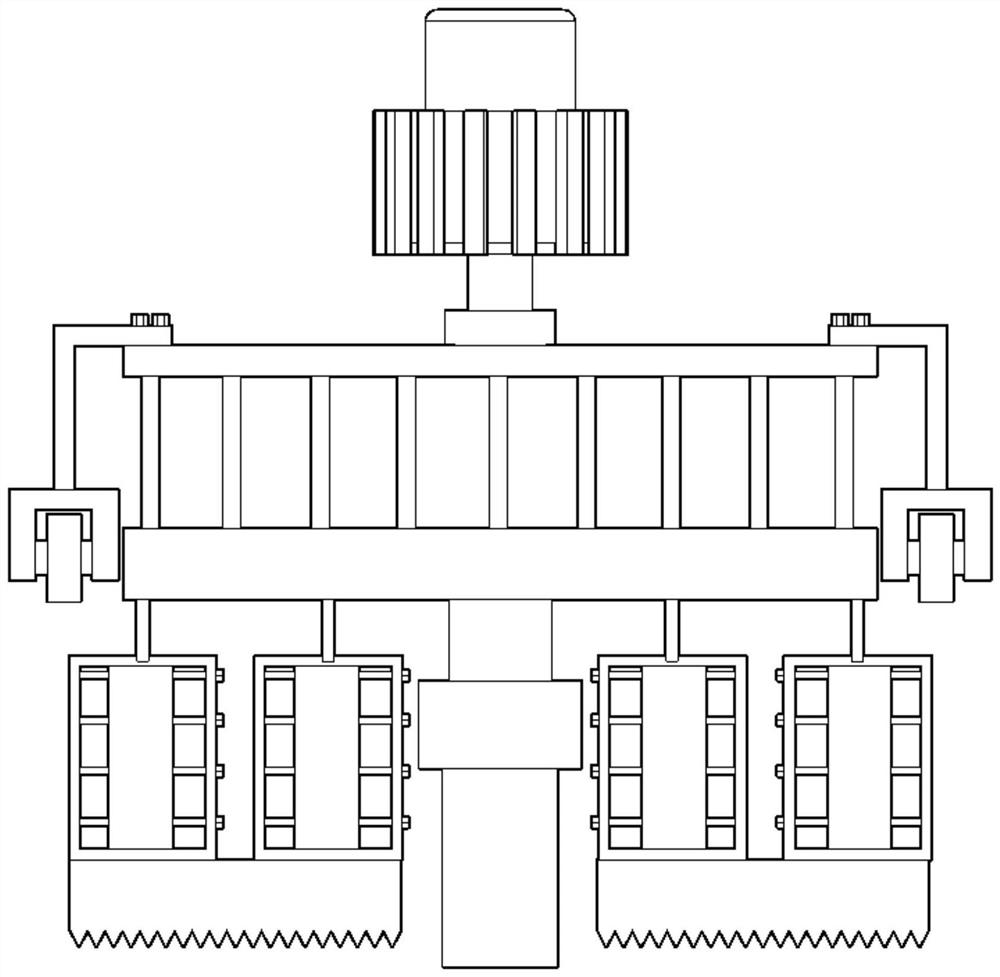

[0039] Such as Figure 1-8 As shown, a skimming mud scraper includes a pillar 9, the top of the pillar 9 is fixedly connected with a turntable seat 81, and the top of the turntable seat 81 is rotatably connected with a rotating column 8, and the top of the rotating column 8 is fixed Connected with a horizontal beam 1.

[0040] The bottom of the above-mentioned horizontal beam 1 is fixedly connected with several mud scraping parts 6 , and the several mud scraping parts 6 are symmetrically distributed on both sides of the pillar 9 . The sludge at the bottom of the sewage tank is scraped off by the scraper 6 .

[0041] The concrete structure of above-mentioned mud scraping part 6 is as follows:

[0042] The mud scraping parts 6 all include a rectangular frame rod 61, and a rectangular opening is opened on the rectangular frame rod 61, and a scraper 62 is arranged in the rectangular opening, and several positioning screws arranged at intervals up and down are threaded on the rec...

Embodiment 2

[0049] Such as Figure 1-8 As shown, a skimming mud scraper includes a pillar 9, the top of the pillar 9 is fixedly connected with a turntable seat 81, and the top of the turntable seat 81 is rotatably connected with a rotating column 8, and the top of the rotating column 8 is fixed Connected with a horizontal beam 1.

[0050] The bottom of the above-mentioned horizontal beam 1 is fixedly connected with several mud scraping parts 6 , and the several mud scraping parts 6 are symmetrically distributed on both sides of the pillar 9 . The sludge at the bottom of the sewage tank is scraped off by the scraper 6 .

[0051] The concrete structure of above-mentioned mud scraping part 6 is as follows:

[0052]The mud scraping parts 6 all include a rectangular frame rod 61, and a rectangular opening is opened on the rectangular frame rod 61, and a scraper 62 is arranged in the rectangular opening, and several positioning screws arranged at intervals up and down are threaded on the rect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com