Workshop scheduling-oriented RFID acquisition method

A technology of workshop scheduling and collection methods, which is applied in the direction of collaborative operation devices, instruments, manufacturing computing systems, etc., and can solve problems such as blocked machine tool processing, different installation time, and changing processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

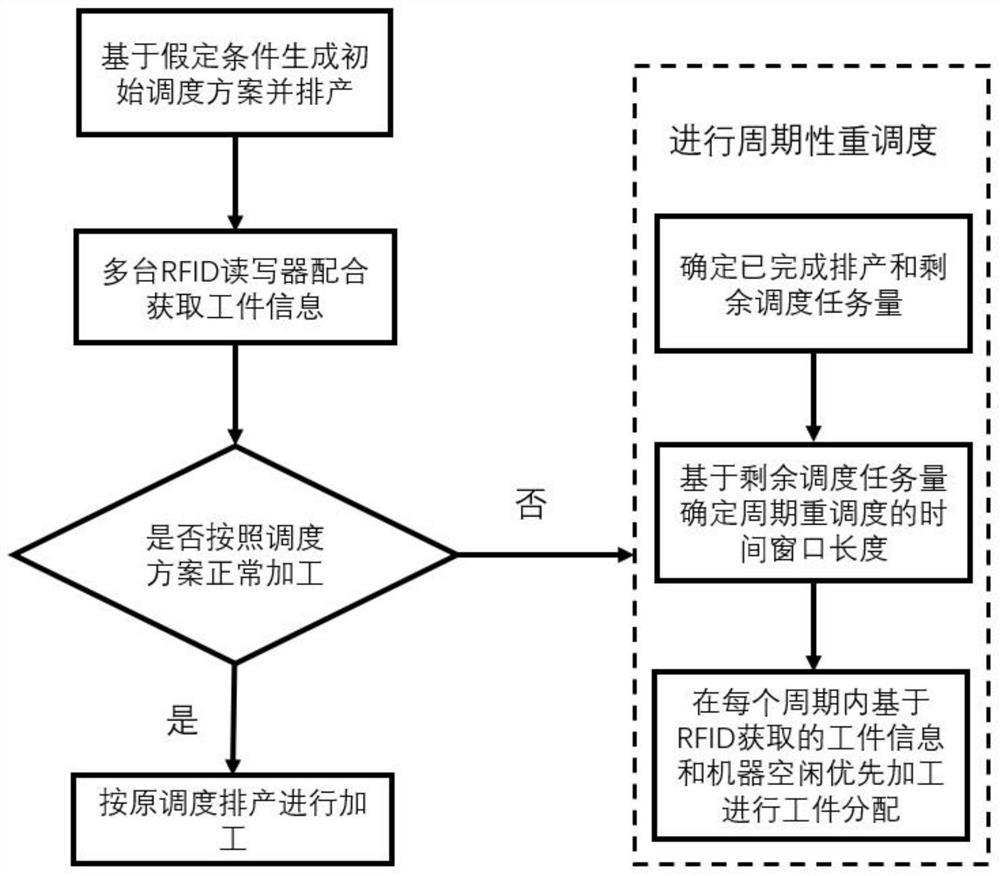

[0036] according to figure 1 , in actual production, based on assumptions and ignoring certain factors for analysis, the production scheduling plan can be quickly generated, which can greatly improve efficiency. At this time, if the processing can be completed according to the initial scheduling plan, the entire processing task will be processed according to the current scheduling. However, this is often not the case in reality. When unpredictable changes occur and the initial production schedule cannot continue, we need to quickly adjust the remaining tasks, and RFID technology can help us obtain the overall situation of the current schedule more quickly. Therefore, we can reschedule within the cycle according to RFID technology to complete the remaining scheduling task requirements.

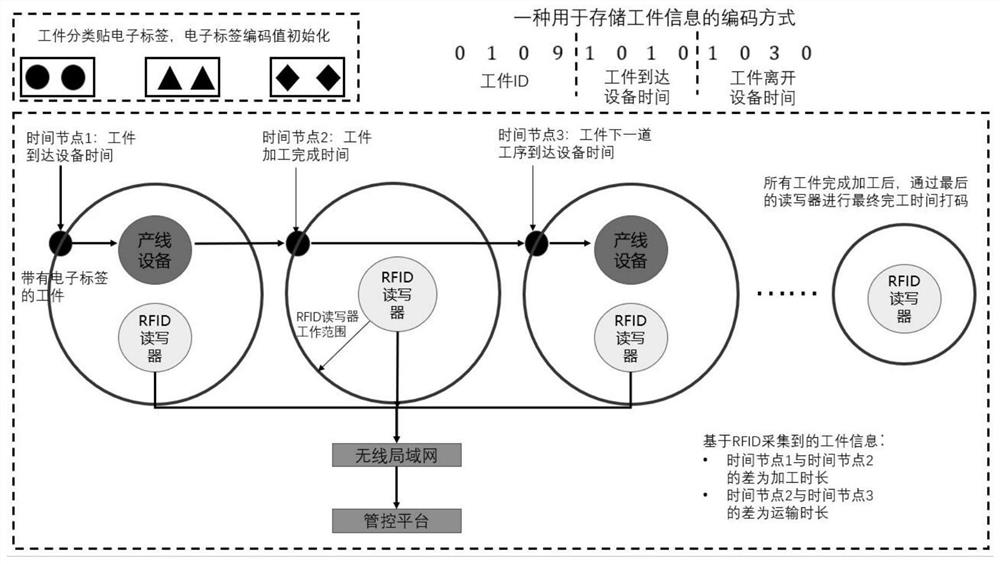

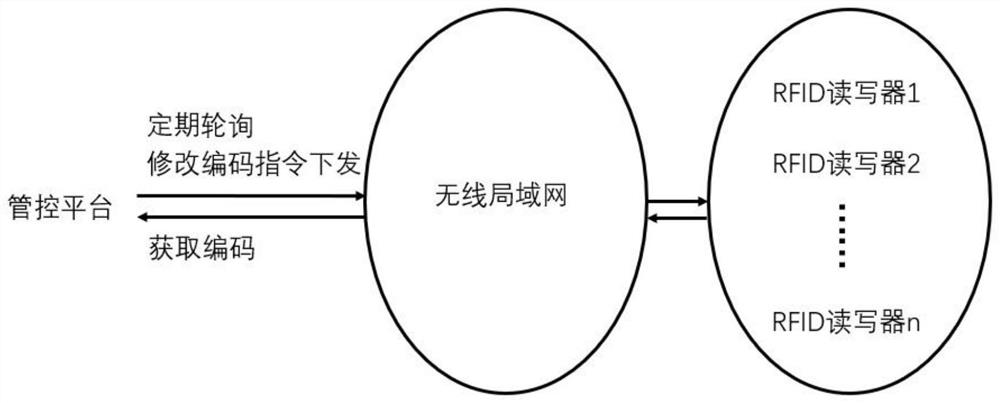

[0037] Therefore, a RFID collection method oriented to workshop scheduling is proposed, such as figure 2 and image 3 As shown, the specific steps are as follows.

[0038] Step 1: Accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com