Cloud VR digital twinning manufacturing production line architecture based on industrial Internet platform and construction method of Cloud VR digital twinning manufacturing production line architecture

An industrial Internet and production line technology, applied in the direction of comprehensive factory control, comprehensive factory control, program control, etc., can solve the problems that data cannot be interacted in real time and continuously, and intelligence and initiative cannot be satisfied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

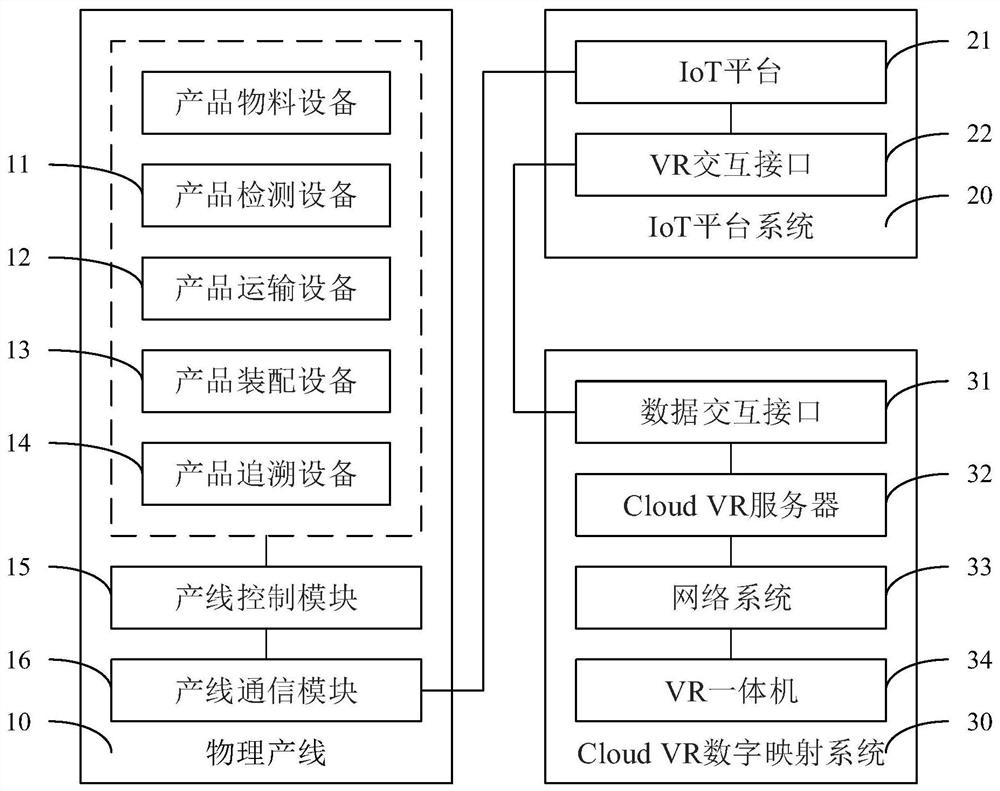

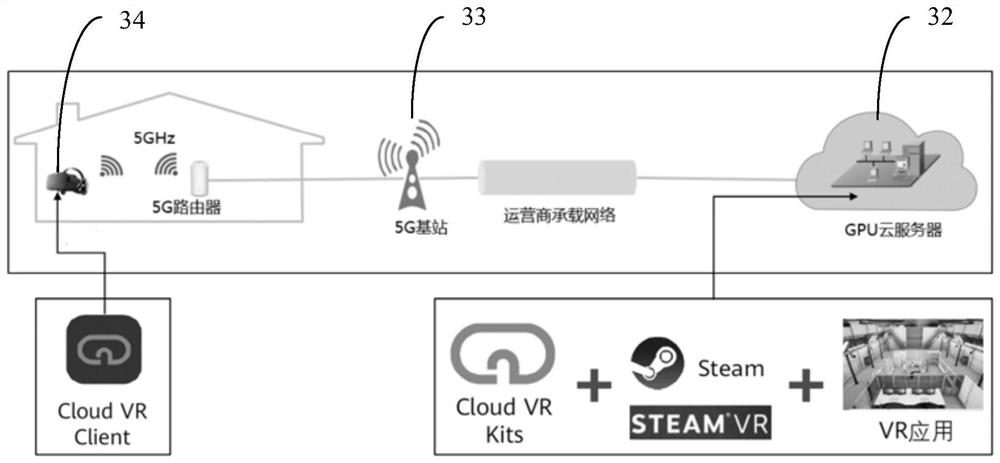

[0029] This embodiment provides a Cloud VR digital twin manufacturing production line architecture based on the industrial Internet platform, such as figure 1 As shown, the architecture includes physical production lines, industrial Internet platform systems, and Cloud VR (Cloud Virtual Reality, cloudification of virtual reality) digital mapping systems. Each component is described in detail below:

[0030] The physical production line is the entity object of the digital twin manufacturing production line, and is the basis of the digital twin manufacturing production line, which mainly includes product equipment, production line control module and production line communication module.

[0031] In this embodiment, the product equipment may include product material equipment, product testing equipment, product transportation equipment, product assembly equipment, and product traceability equipment. Product material equipment such as feeding robots, material boxes, etc.; product...

Embodiment 2

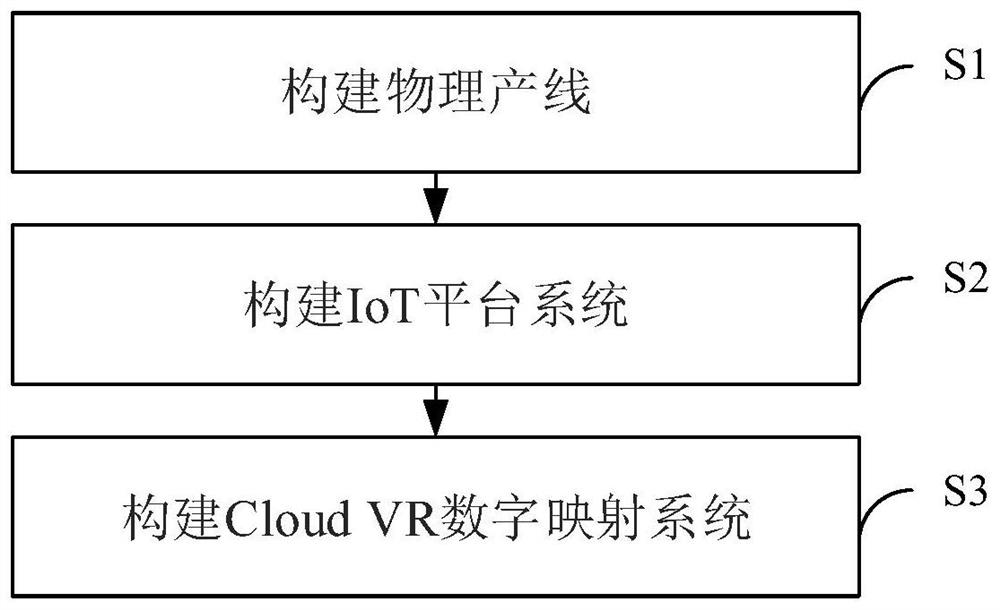

[0043] This embodiment provides a method for constructing a Cloud VR digital twin manufacturing production line architecture based on an industrial Internet platform, such as image 3 As shown, the method includes the following steps:

[0044] S1, build a physical production line, the physical production line is the entity object of the digital twin manufacturing production line, and is the basis of the digital twin manufacturing production line, which mainly includes product equipment, production line control module and production line communication module.

[0045] In this embodiment, the product equipment may include product material equipment, product testing equipment, product transportation equipment, product assembly equipment, and product traceability equipment. Product material equipment such as feeding robots, material boxes, etc.; product testing equipment such as CCD detection camera systems, etc.; product transportation equipment mainly includes AGV trolley system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com