A Design Method for Beam Shaping of Spherical Air Chamber Pumped Laser System

A beam shaping and laser system technology, which is applied in the field of extremely weak magnetic detection, can solve the problems of polarization spot deviation, complexity and unevenness of the installation process, and achieve the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and according to the operation sequence of the flowchart.

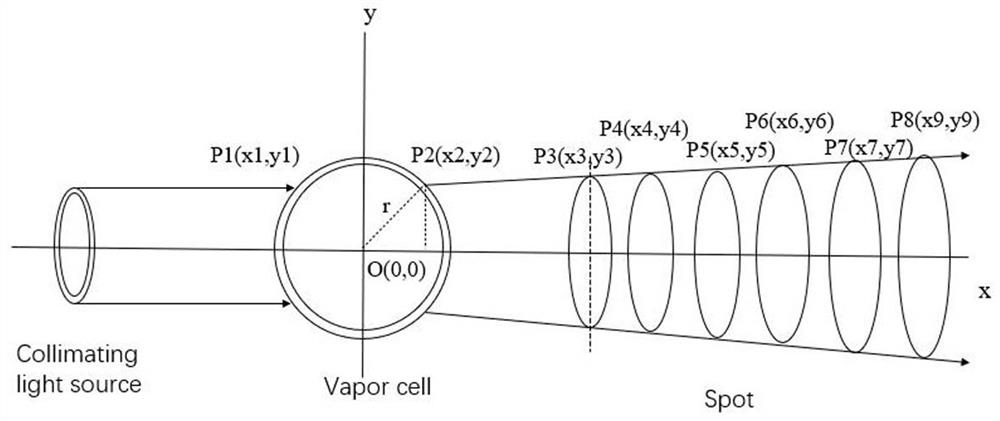

[0044] (a) Use a beam quality analyzer to test the spot size passing through the air chamber at multiple locations, fit the tested spot size by the least squares method, and calculate the intersection of the refracted light after passing through the spherical air chamber and the air chamber;

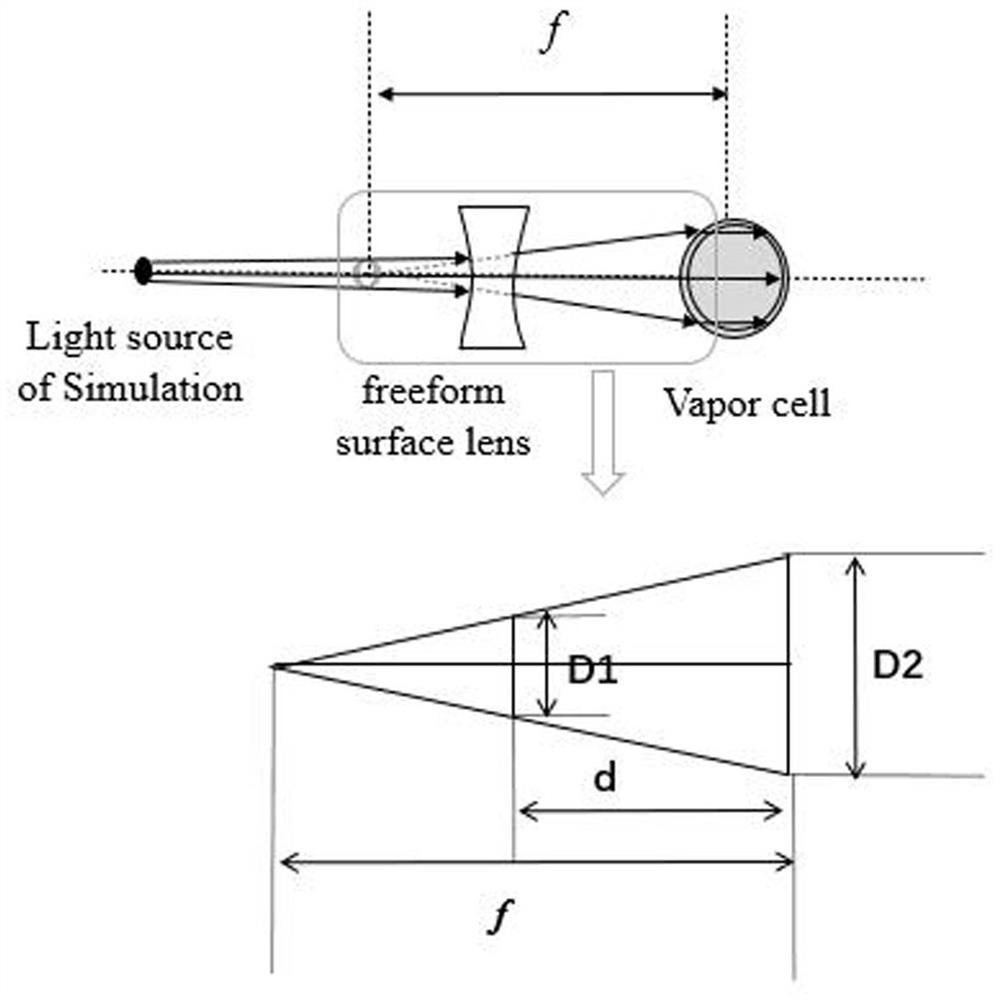

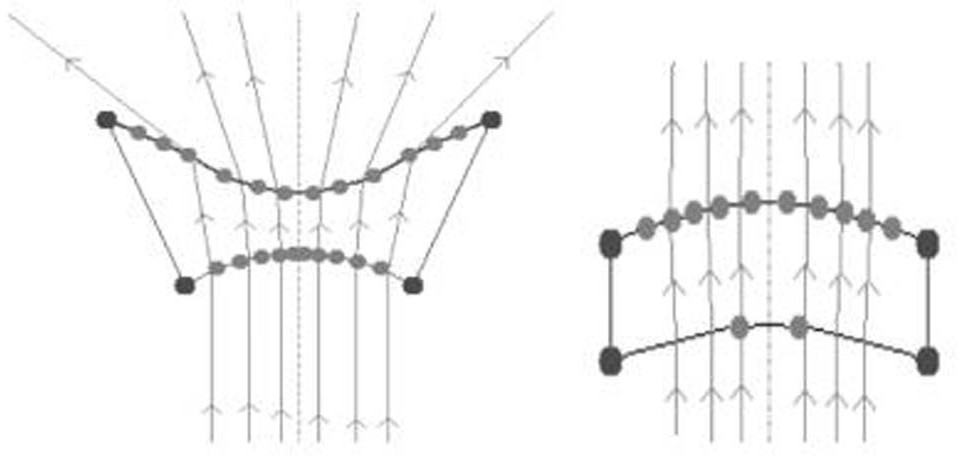

[0045] (b) Based on the Tracepro software, under the premise of collimated laser incidence, adjust the refractive index and thickness of the air cell so that the position coordinates of the intersection point between the simulated light ray and the air cell after being refracted by the spherical air cell and the coordinates of the intersection point calculated in step (1) consistent;

[0046] (c) Calculate the focal length of the gas cell based on geometric optics and the law of refraction and reflection of light;

[0047]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com