Method for increasing concentration of carbon dioxide in flue gas

A technology of carbon dioxide and flue gas, which is applied in combustion methods, non-flammable liquid/gas transportation, waste heat treatment, etc., can solve the problems of expensive and economical costs, and achieve the effect of reducing the formation of NOx

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

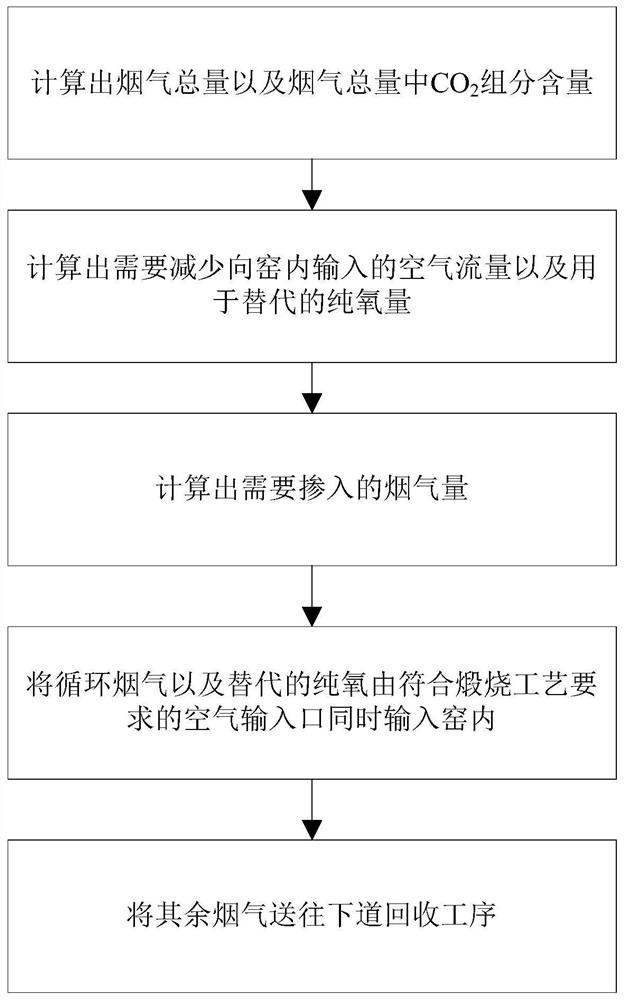

[0019] Such as figure 1 As shown, the present invention provides a method for increasing the concentration of carbon dioxide in flue gas, comprising the following steps:

[0020] Step 1, according to CaCO 3 Decompose the chemical equation to calculate the CO under the design output 2 The amount of generation per unit time, and then according to the input amount of air and fuel per unit time required by the calcination process and the combustion chemical equation of each combustible component in the fuel to calculate the generation amount and composition of combustion products per unit time, and then CaCO 3 CO decomposed during calcination 2 Add the combustion products to calculate the total amount of flue gas and the CO in the total amount of flue gas 2 Component content;

[0021] Step 2, according to the total amount of flue gas, CO in the total amount of flue gas 2 Component content and target CO 2 Concentration calculated to reduce N input to the kiln 2 flow, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com