Fabricated building wallboard hoisting device

A hoisting device and building wall technology, which is applied in construction, building structure, building material processing and other directions, can solve the problems of wall panel bumping, damage, hydraulic rod deformation, etc., and achieve the effect of improving hoisting efficiency and increasing scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

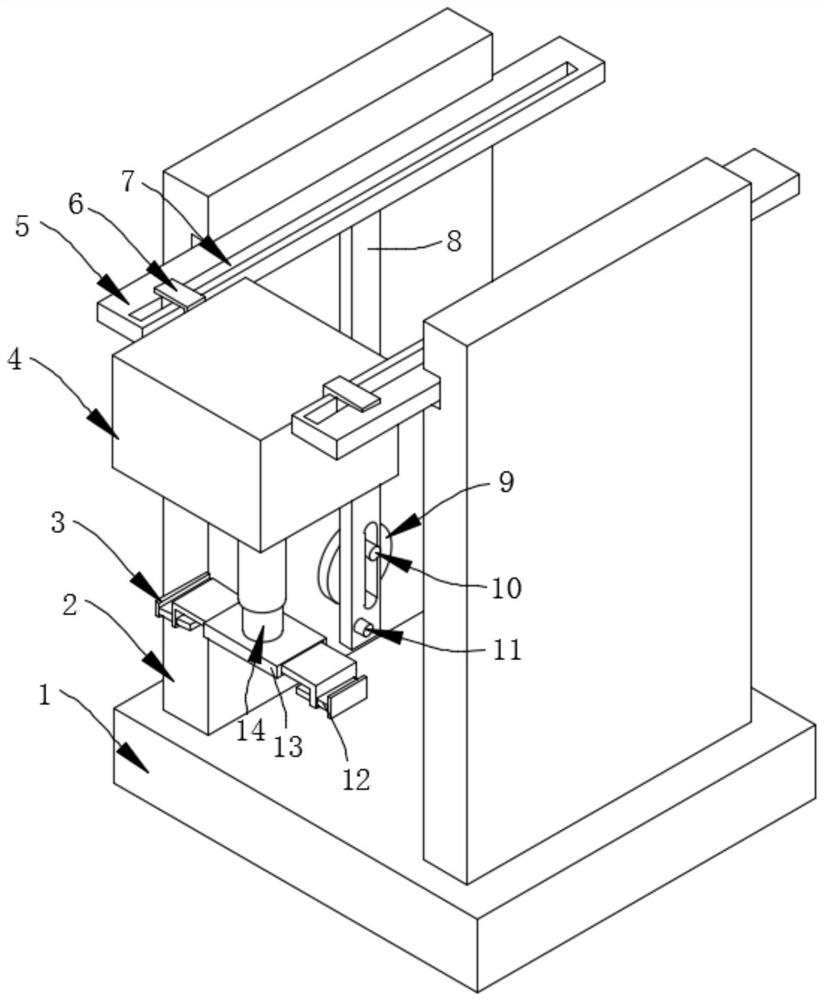

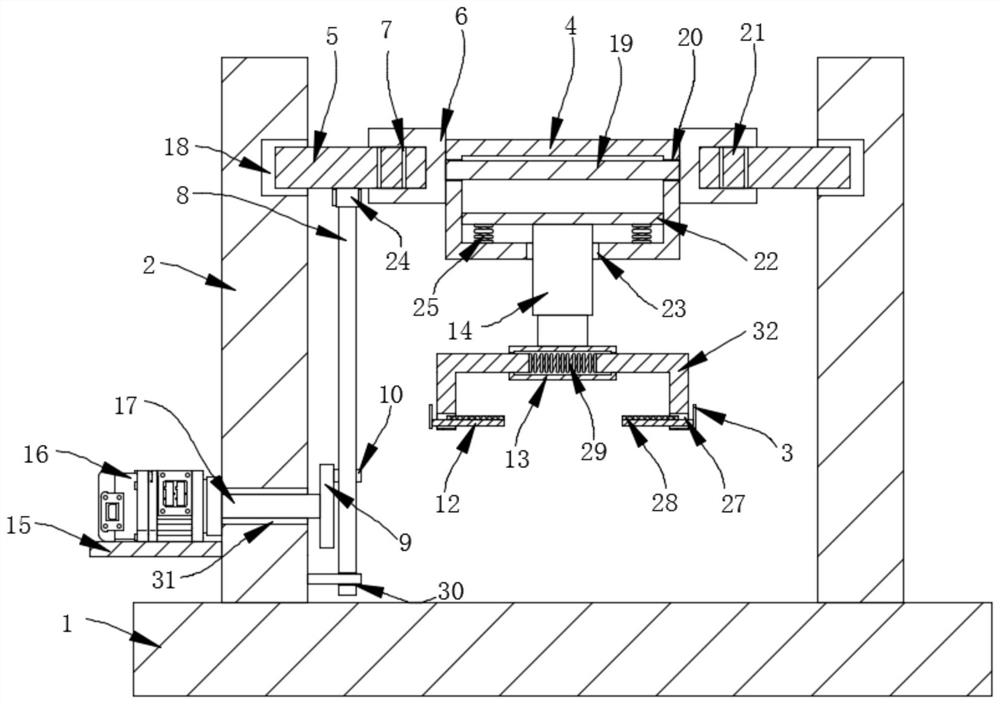

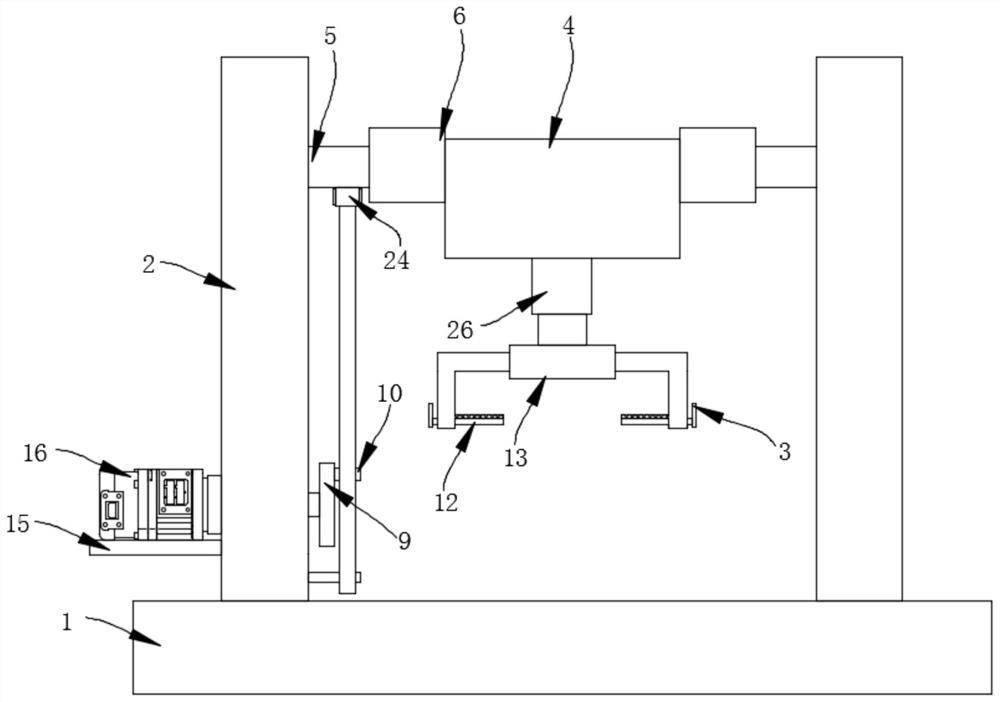

[0028] see Figure 1-6 , the present invention provides a technical solution: a prefabricated building wall panel hoisting device, including a fixing seat 1, two supporting plates 2 are symmetrically welded on the upper surface of the fixing seat 1, and the adjacent sides of the two supporting plates 2 are A groove 18 is provided, and the inside of the groove 18 is slidably connected with the first plate body 5, and one side of a support plate 2 is welded with a fourth plate body 15, and a motor 16 is installed on the upper surface of the fourth plate body 15, and the motor 16 The output end of the rotating rod 17 is welded with a rotating rod 17, and one side of a support plate 2 is provided with a second through hole 31, and the end of the rotating rod 17 away from the motor 16 penetrates the inside of the second through hole 31 and is welded with a second plate body 9. The second plate body 9 is welded with the first rod body 10 away from the side of the rotating rod 17, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com