Drying and shaping equipment for chemical fiber processing

A chemical fiber drying technology, used in lighting and heating equipment, progressive dryers, drying solid materials, etc., can solve the problems of chemical fiber strength and elongation reduction, large temperature jumps, etc., to achieve good absorption and improvement. The effect of quality, improved quality and production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

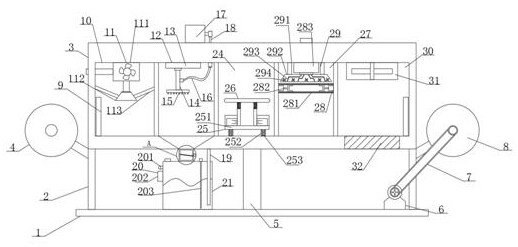

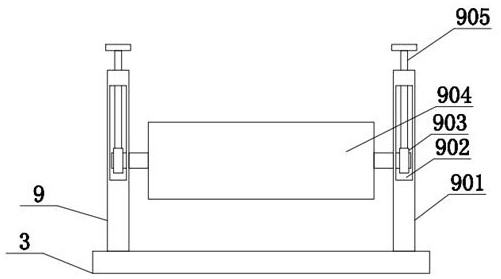

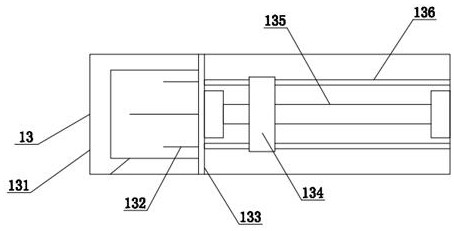

[0038]SeeFigure 1-6, A drying and setting equipment for chemical fiber processing, comprising a base 1, the upper end of the base 1 is fixedly connected to the left and right sides of the support column 2, the upper end of the support column 2 is fixedly connected to the same shell 3, the shell The middle of the lower end of the body 3 is fixedly connected with a reinforcement column 5, the other end of the reinforcement column 5 and the base 1 are fixedly connected, the left side of the column 2 is fixedly connected with a feed roller 4, and the right side of the column 2 is fixed The receiving roller 8 is connected, the upper end of the base 1 is fixedly connected with a first motor 6, and the output end of the first motor 6 and the shaft of the receiving roller 8 are both rotatably connected to the same conveyor belt 7, and the shell The inner side of the body 3 is provided with a dehumidification chamber 10, a spray chamber 12, an absorption chamber 24, a drying chamber 27, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com