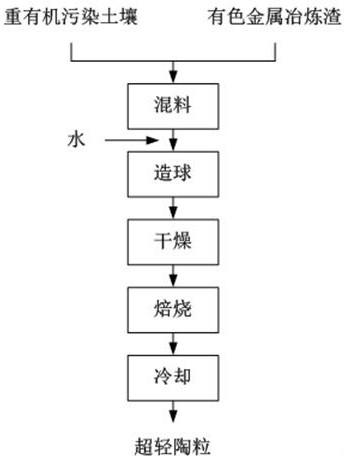

Method for preparing ultralight ceramsite by utilizing heavy organic contaminated soil and non-ferrous metal smelting slag

A technology of organic pollution and non-ferrous metals, which is applied in the field of soil remediation and can solve problems such as residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] A method for preparing ultra-light ceramsite by using heavy organic polluted soil and non-ferrous metal smelting slag comprises the following steps:

[0081] The inorganic composition (inorganic matter is calculated as oxide) and the content of organic pollutants of the heavily organically polluted soil used in this embodiment are as follows: SiO 2 The content is 59.23wt%, Al 2 o 3 The content is 14.36wt%, Fe 2 o 3 content of 0.76wt%, CaO content of 10.86wt%, MgO content of 7.15wt%, K 2 O content is 0.68wt%, Na 2 The O content is 1.22wt%, the organic pesticide content is 9850mg / kg, the petroleum hydrocarbon content is 48901mg / kg, the polycyclic aromatic hydrocarbon content is 8964mg / kg, and the polychlorinated biphenyl content is 483mg / kg. The inorganic components of copper smelting tailings (both calculated as oxides) are as follows: SiO 2 The content is 51.26wt%, Al 2 o 3 The content is 24.18wt%, Fe 2 o 3 content of 8.85wt%, CaO content of 13.74wt%, MgO cont...

Embodiment 2

[0088] A method for preparing ultra-light ceramsite by using heavy organic polluted soil and non-ferrous metal smelting slag comprises the following steps:

[0089] The inorganic composition (inorganic matter is calculated as oxide) and the content of organic pollutants of the heavily organically polluted soil used in this embodiment are as follows: SiO 2 The content is 32.46wt%, Al 2 o 3 The content is 6.48wt%, Fe 2 o 3 content of 4.59wt%, CaO content of 5.97wt%, MgO content of 2.64wt%, K 2 O content is 0.78wt%, Na 2 The O content is 1.67wt%, the organic pesticide content is 4951 mg / kg, the petroleum hydrocarbon content is 38942 mg / kg, the polycyclic aromatic hydrocarbon content is 7968 mg / kg, and the polychlorinated biphenyl content is 408 mg / kg. The inorganic components of lead smelting tailings (both calculated as oxides) are as follows: SiO 2 The content is 67.48wt%, Al 2 o 3 The content is 24.58wt%, Fe 2 o 3 content of 8.64wt%, CaO content of 14.58wt%, MgO cont...

Embodiment 3

[0096] A method for preparing ultra-light ceramsite by using heavy organic polluted soil and non-ferrous metal smelting slag comprises the following steps:

[0097] The inorganic composition (inorganic matter is calculated as oxide) and the content of organic pollutants of the heavily organically polluted soil used in this embodiment are as follows: SiO 2 The content is 45.89wt%, Al 2 o 3 The content is 8.45wt%, Fe 2 o 3 content of 9.45wt%, CaO content of 14.15wt%, MgO content of 10.46wt%, K 2 O content is 1.05wt%, Na 2 The O content is 1.46wt%, the organic pesticide content is 8912mg / kg, the petroleum hydrocarbon content is 41320mg / kg, the polycyclic aromatic hydrocarbon content is 8612mg / kg, and the polychlorinated biphenyl content is 316mg / kg. The inorganic components of zinc smelting tailings (both calculated as oxides) are as follows: SiO 2 The content is 61.46wt%, Al 2 o 3 The content is 21.46wt%, Fe 2 o 3 content of 10.46wt%, CaO content of 4.75wt%, MgO conten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap