A Guideable Material Automatic On-line System

An automatic online and material technology, applied in the directions of transportation, packaging, storage devices, etc., can solve problems such as the risk of taking wrong parts, low efficiency, and increased transfer links, etc., to achieve automatic docking and detachment, the system is simple and practical, and reduce errors. Piece rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

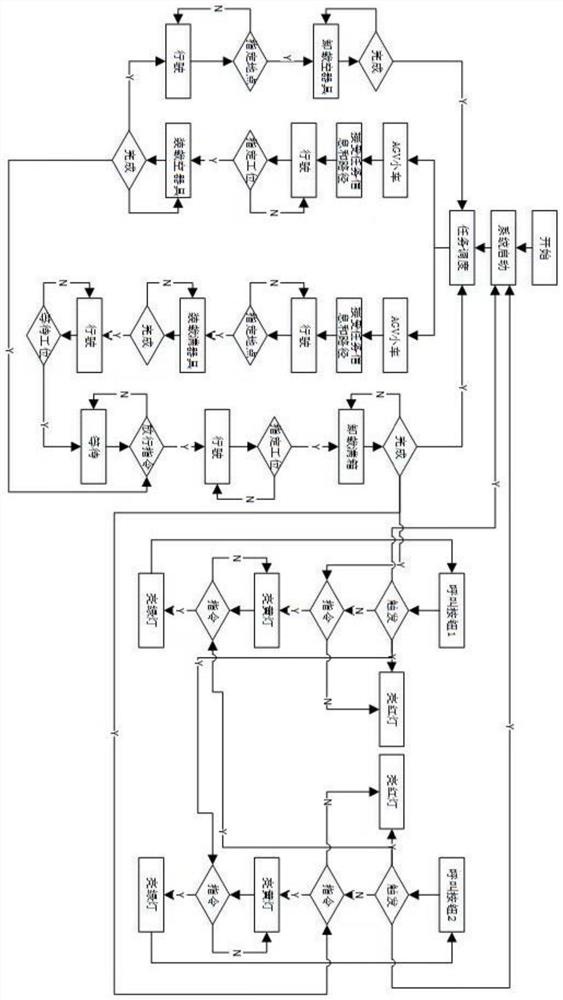

Method used

Image

Examples

Embodiment

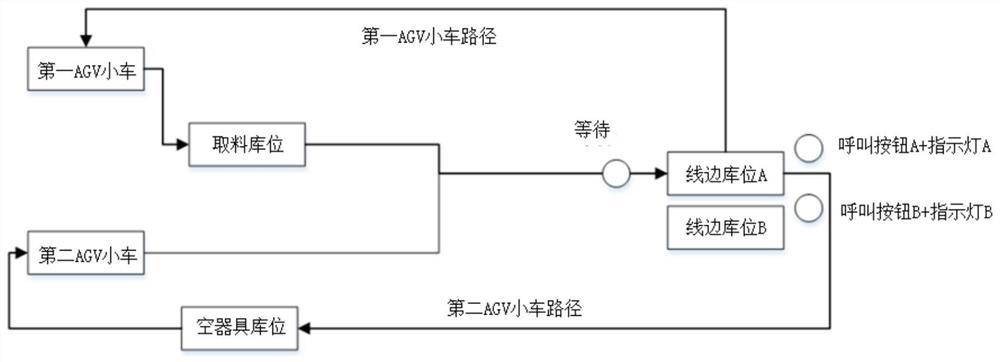

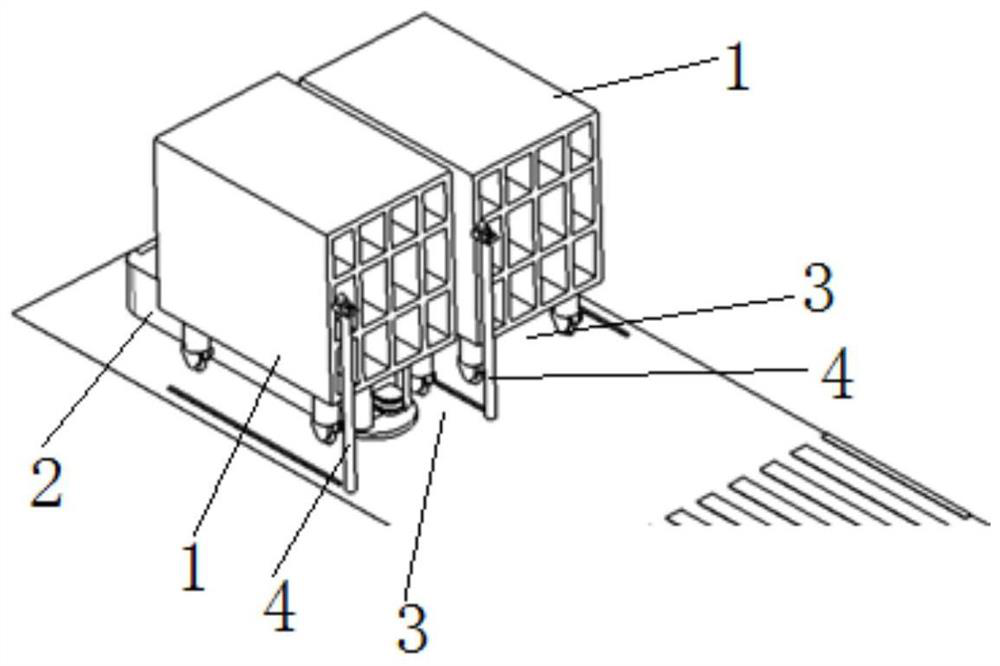

[0033] A guideable automatic material loading system, including adjacent line side storage location A, line side storage location B, indicator light 5A and call button 6A at line side storage location A, line side storage location B Indicator light B and call button B, the first AGV car, the second AGV car and the dispatch control system. Indicator light 5 and call button 6 are installed on the pole 4 on one side corresponding to line edge storage position 3, as Figure 4 As shown; a serial part is provided with two line edge storage locations 3, and when the materials in one line edge storage location 3 are used up, the other line edge storage location 3 can be put into use immediately to ensure continuous supply of materials. The first AGV trolley and the second AGV trolley can cooperate to feed materials into a lineside storage position 3 . like figure 2 As shown, taking the delivery of materials to the lineside storage location A as an example, the first AGV trolley tak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com