Defect detection method and system for particles in bubble cap plate based on vision

A defect detection and blister board technology, which is applied in the directions of optical testing defects/defects, measuring devices, instruments, etc., can solve the problem of high cost, and achieve the effects of low cost, low extraction difficulty and high detection reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

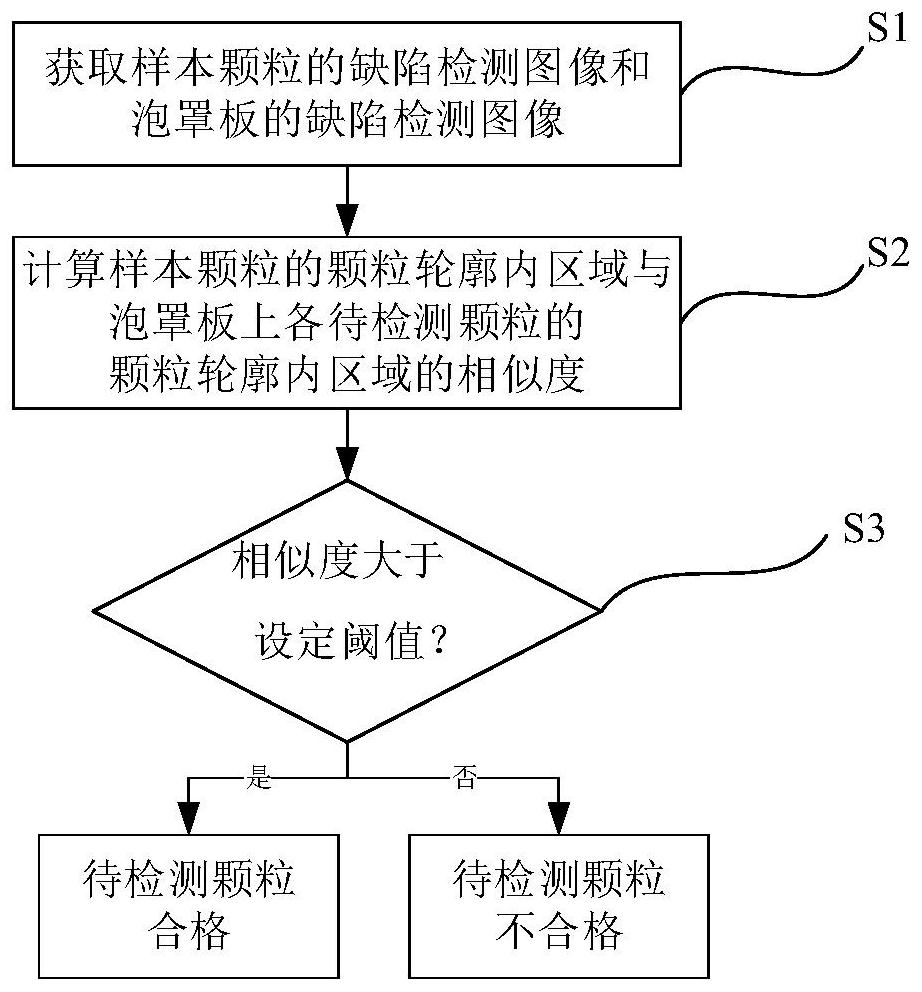

[0036] A vision-based defect detection method for particles in blister sheets, which are in the shape of circular flakes such as figure 1 , the method is specifically:

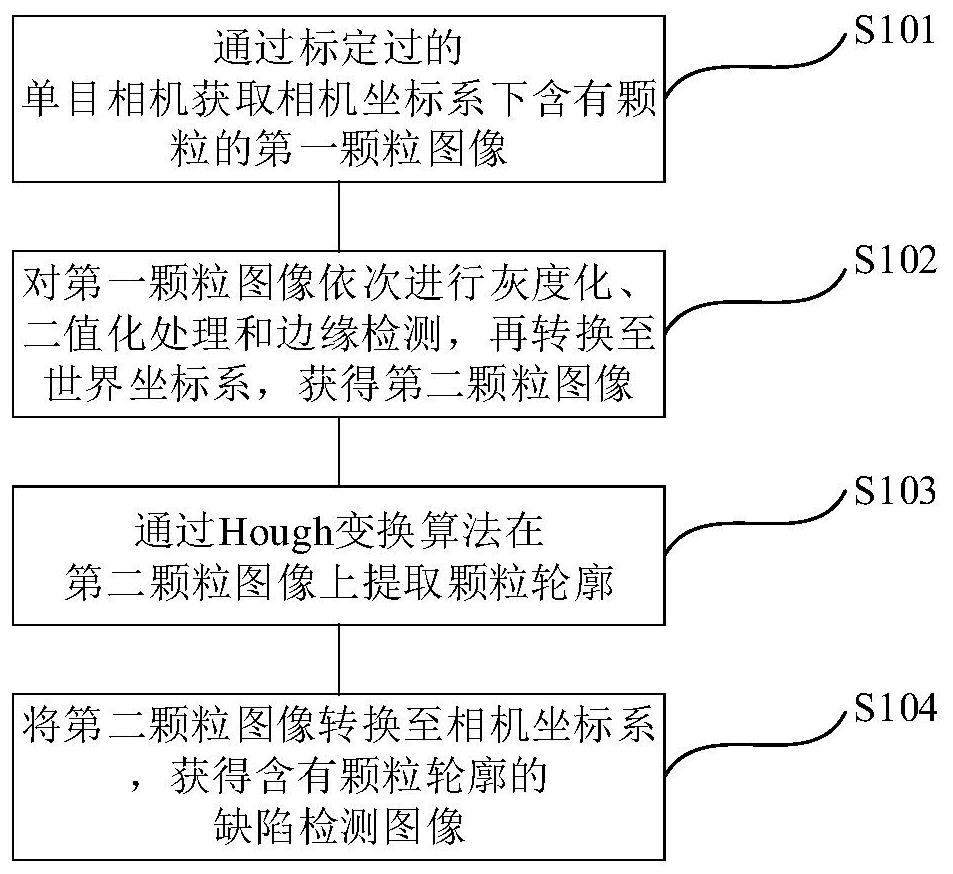

[0037] S1: Obtain the defect detection image P of the sample particles 1 and the defect detection image of the blister plate P 2 , P 1 Particle profile containing sample particles, P 2 Contains the particle profile of each particle to be detected on the blister plate;

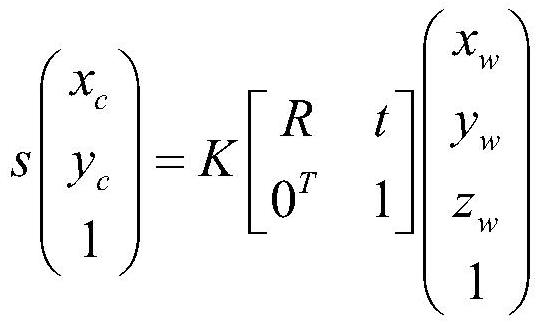

[0038] S2: Through the image similarity function Sim(B 0 , B 1 ) Calculate the similarity of the area in the particle outline of the sample particle and the area in the particle outline of the particle to be detected, B 0 is the apparent information of the area within the particle outline of the sample particle, B 1 is the apparent information of the area within the particle outline of the particle to be detected, Sim(B 0 , B 1) is the product of the color similarity function and the structural similarity function, the structural simil...

Embodiment 2

[0054] In this embodiment, the shape of the particles is capsule-like, the particle profile is a waist-shaped profile, and the size parameters of the particle profile are the diameters and the distance between the centers of the two semicircles of the waist-shaped profile, and the error between the diameter of the two semi-circles and the set diameter is equal It is within the error range of the set diameter, and the error between the distance between the centers of the two semicircles and the set distance is also within the error range of the set distance. Others are the same as in Example 1.

Embodiment 3

[0056] In this embodiment, the image similarity function is a similarity function based on deep learning, and the others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com