Method for reinforcing hollow plate girder bridge by adopting corrugated steel plates and UHPC

A technology of hollow slab girders and hollow slabs, which is applied in bridge reinforcement, bridge maintenance, etc., can solve problems such as weak lateral connections, stress on single slabs, and damage to hinge joints, so as to enhance lateral integrity, enhance bearing capacity, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to have a deeper understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

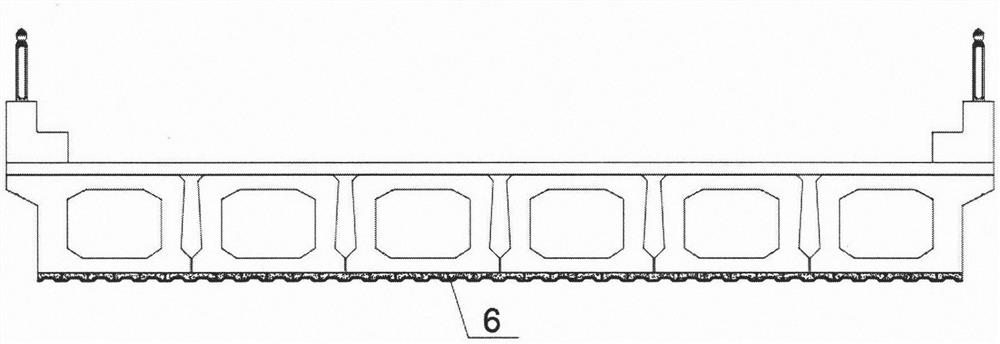

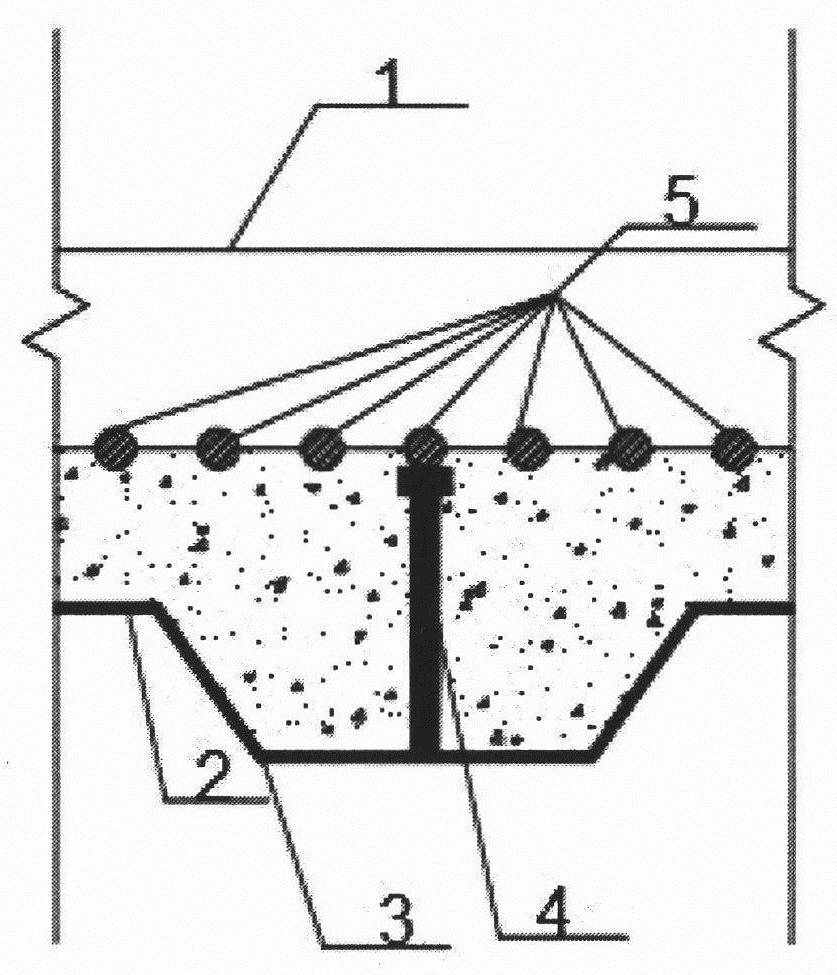

[0029] Please refer to the figure, in the example of the present invention, a kind of method that adopts corrugated steel plate and UHPC to strengthen the hollow slab girder bridge, the concrete surface of the original hollow slab girder bridge bottom plate 1 is processed, removes the original reinforcement protective layer, and the reinforcement of the original structure 5 is welded together with the welding stud 4 arranged on the corrugated steel plate 3, and is integrated by pouring UHPC2, so that the reinforcement part 6 and the original structure form a whole to work together.

[0030] The method for strengthening the hollow slab girder bridge with corrugated steel plate and UHPC is characterized in that the length of the weld...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com