A multifunctional rod cold drawing die set and cold drawing method

A multi-functional, die set technology, applied in wire drawing dies and other directions, can solve the problems of difficulty in precise control of rod shape accuracy, difficulty in drawing control, pipe wall rupture, etc., to achieve convenient installation of external equipment, high manufacturing efficiency, The effect of ensuring structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

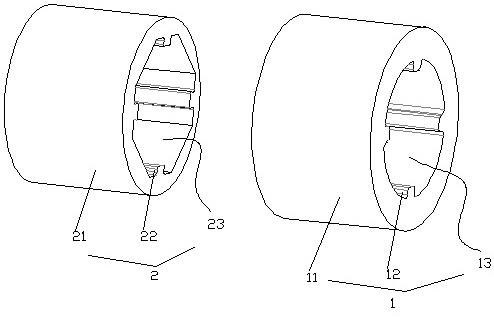

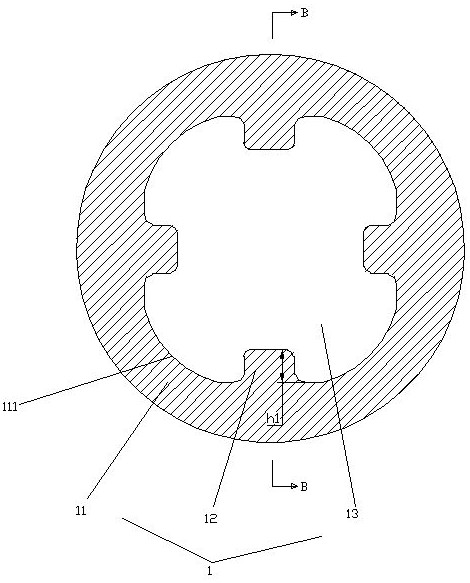

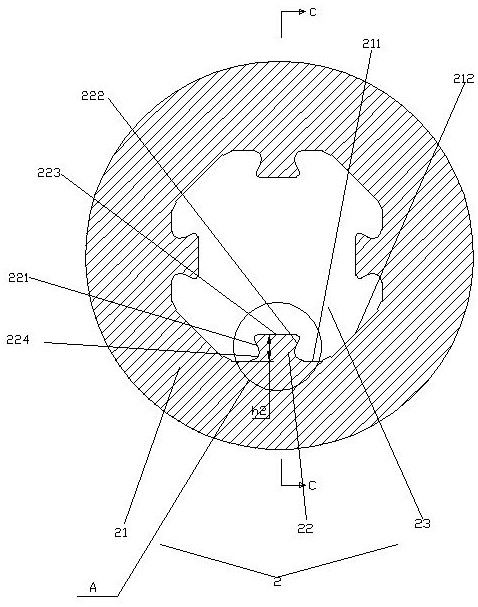

[0053] Embodiment 1: as Figure 1-6 As shown, a multi-functional rod cold drawing die set includes a straight groove drawing die 1 and a curved angle drawing die 2, wherein the straight groove drawing die 1 is arranged on the installation cylinder one 11 by the installation cylinder one 11 The straight groove drawing part 12 on the inner wall is composed of at least one straight groove drawing part 12. The straight groove drawing part 12 and the inner wall of the installation cylinder 11 form a cold drawing hole 13, and the cold drawing hole 13 The outlet is smaller than the inlet, and the outlet is preferably 80% to 99% of the size of the inlet. The angle drawing mold 2 is composed of the installation cylinder 21 and the angle drawing part 22 arranged on the inner wall of the installation cylinder 21. Composed, the curved angle drawing part 22 corresponds to the straight groove drawing part 12, and is used to bend the straight groove drawn by the straight groove drawing part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com