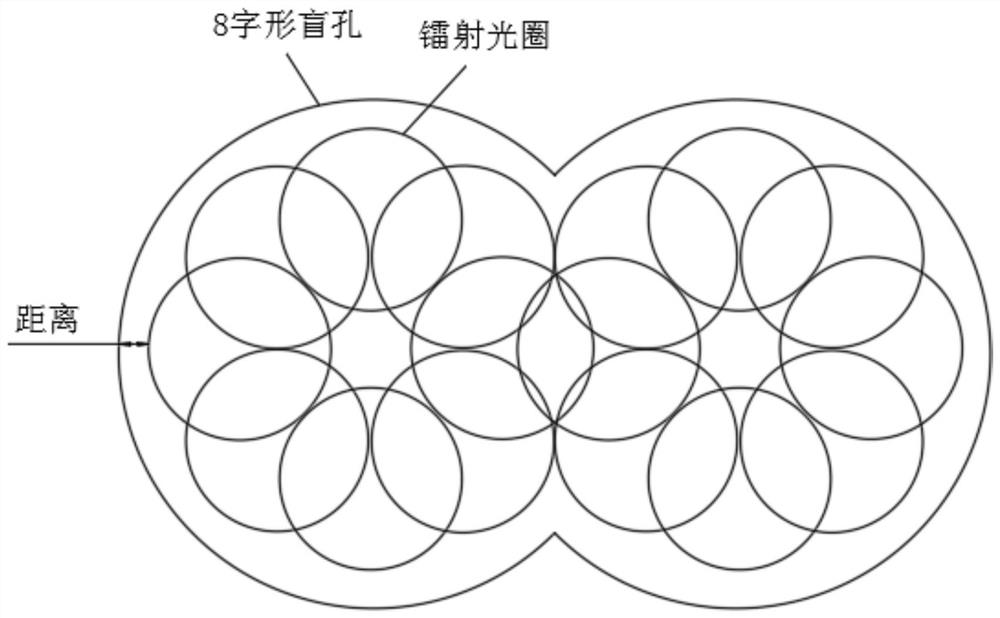

Manufacturing method of figure 8 blind hole in printed circuit board

A technology of printed circuit boards and manufacturing methods, which is applied in the direction of printed circuit manufacturing, printed circuits, electrical components, etc., can solve the problems of small blind hole diameter, thin dielectric layer, separation, etc., and achieve the effect of ensuring speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] Embodiment: a manufacturing method of a figure-8 blind hole in a printed circuit board, comprising the following steps:

[0036] S1. Slicing: cut the substrate plate to an appropriate size, and bake it in an oven at 120-170°C for 2-4 hours to release the internal stress of the substrate plate;

[0037] S2. Inner layer circuit: Etch the inner layer circuit. After the inner layer circuit is fabricated, scan the board surface with an optical inspection machine to ensure that there is no gap on the PAD at the bottom of the circuit / blind hole;

[0038] S3. Outer copper window: The required blind hole aperture is etched by opening the copper window. The compensation method of the copper window compensates the aperture size according to the copper thickness. When the copper thickness is 8 mil, the opening diameter of the copper window needs to be increased by 1 mil. ;

[0039] S4. Laser laser: Blind holes are burned out in the way of laser laser copper window. When the copper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com