Active control method and system for improving AGC control performance of wind power plant

A technology of control performance and control method, which is applied in the direction of wind power generation, electrical components, circuit devices, etc., and can solve the problem of deviation from distribution value, large error of wind turbine speed and pitch control, and AGC adjustment accuracy of wind farm does not meet the limit requirements, etc. problem, achieve the effect of improving control performance and shortening response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with specific examples.

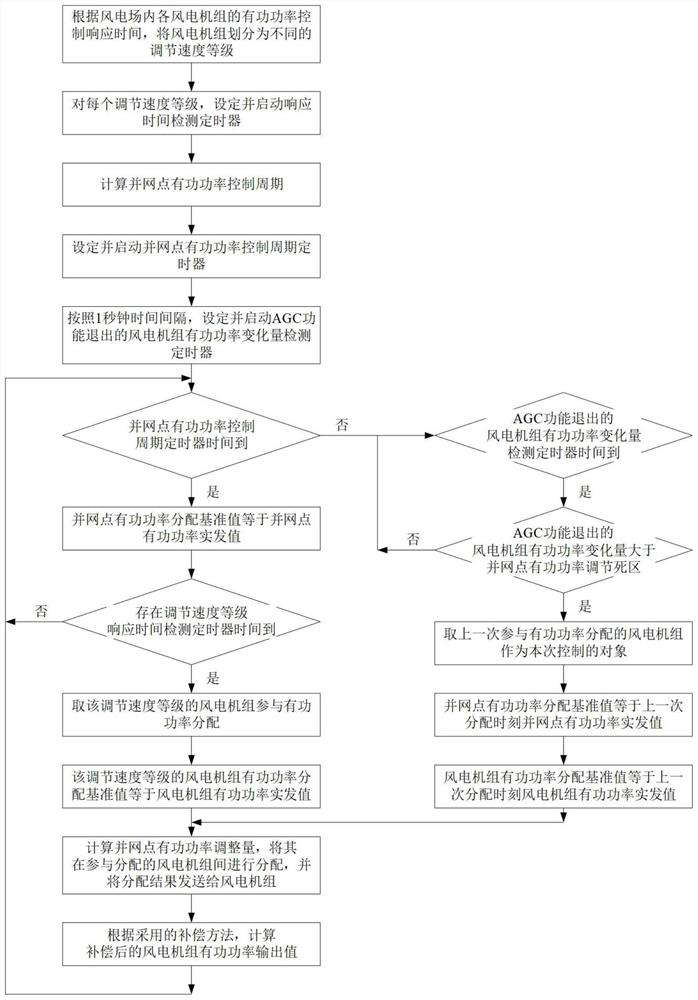

[0036] like figure 1 As shown, an active power control method for improving the AGC control performance of a wind farm includes the following steps:

[0037] Step 1): According to the active power control response time of each controllable wind turbine in the wind farm, divide the controllable wind turbine into different adjustment speed levels.

[0038] Further, the adjustment speed level division method in the step 1) is: from the minimum value to the maximum value of the active power control response time of the controllable wind turbine, it is divided into N intervals on average, and each interval corresponds to an adjustment Speed level, each controllable wind turbine is classified into the interval corresponding to each adjustment speed level according to the active power control response time, and the upper limit value of each interval is taken as the equivalent resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com