Fuel cell cold start rapid test system

A fuel cell and test system technology, applied in fuel cells, fuel cell additives, circuits, etc., can solve the problems of high cold start test cost, shortened test time, long time consumption, etc., and achieves good control effect, shortened test time, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

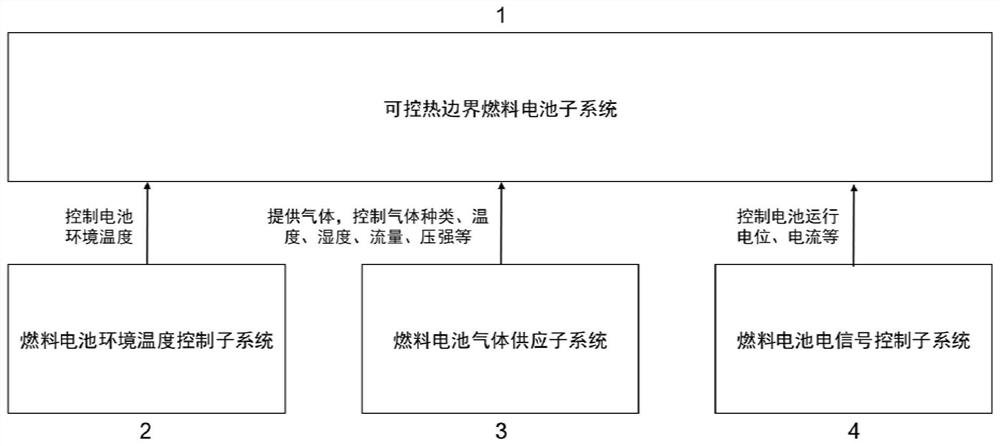

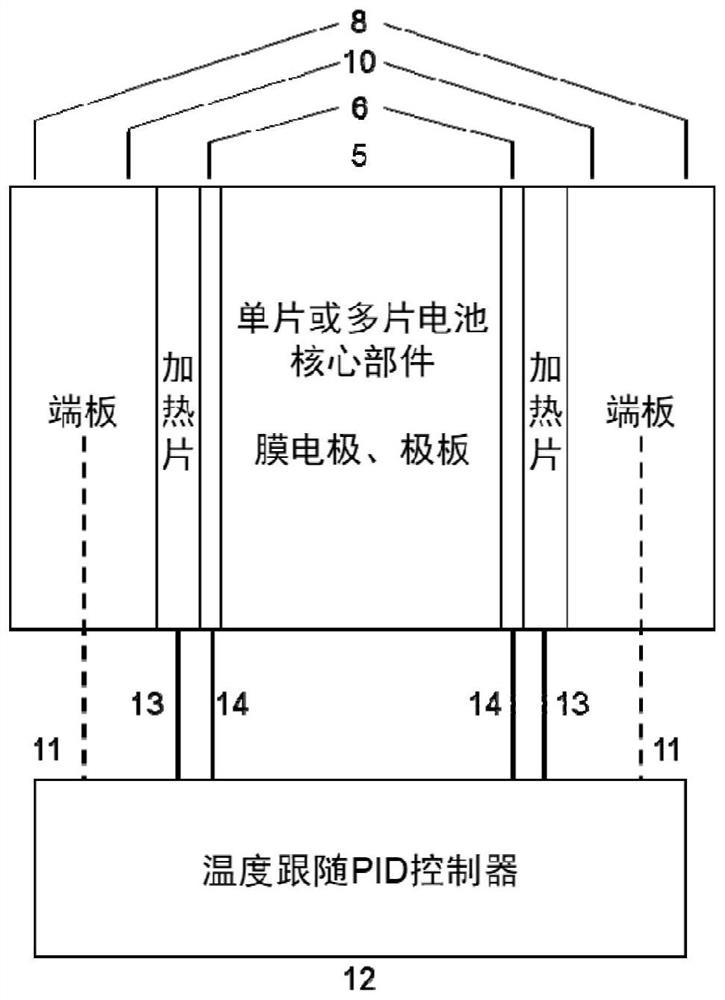

[0034] A fuel cell cold start fast test system according to Example 1 of the present invention characterizes the cold start performance of the fuel cell by testing the cold start performance of the core components of the fuel cell (including membrane electrodes and plates). The overall structure of the test system in this embodiment can be found in figure 1 , including a controllable thermal boundary fuel cell subsystem 1 , a fuel cell ambient temperature control subsystem 2 , a fuel cell gas supply subsystem 3 and a fuel cell electrical signal control subsystem 4 . When the test system is working, the fuel cell ambient temperature control subsystem 2 controls the ambient temperature of the fuel cell, the fuel cell gas supply subsystem 3 is connected to the controllable thermal boundary fuel cell subsystem 1 through gas pipelines, and the fuel cell electrical signal control subsystem 4 is connected with the controllable thermal boundary fuel cell subsystem 1 through voltage an...

Embodiment 2

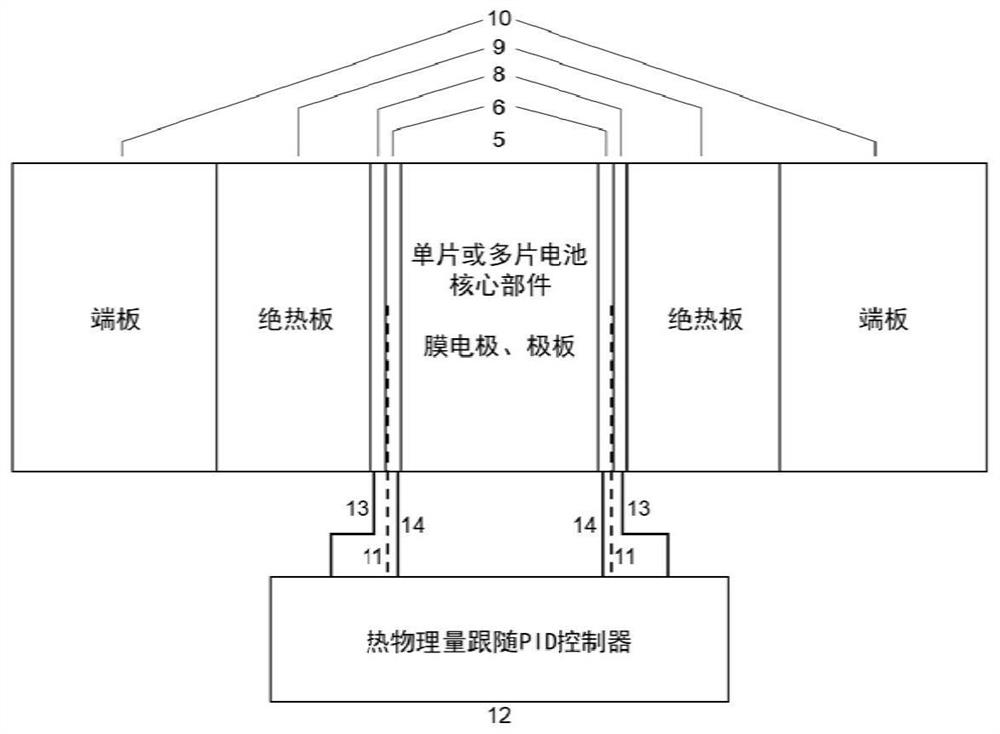

[0040] see image 3 , The difference between this embodiment and Embodiment 1 lies in the fuel cell subsystem 1 with a controllable thermal boundary. Among them, the heat-regulating component is composed of a heating sheet 8 attached to the outside of the current collector 6 and a heat insulating plate 9 attached to the outside of the heating sheet 8. The end plate 10 is located outside the heat insulating plate 9, and the heat insulating plate 9 can reduce the heating sheet 8 to the end. Plate 10 measured heat dissipation. The active area of the core component of the monolithic battery is 4cm 2 The material of the pole plate is expanded graphite with a thickness of 1 mm and an active area ratio of 0.5. A thermophysical quantity sensor 11 is attached to the outside of the pole plate or the outside of the current collector (here is a heat flux sensor, and the measurable heat flux range is 0~ 50W / cm 2 ), which can monitor the heat flux between the pole plate and the current...

Embodiment 3

[0043] see Figure 4 , The difference between this embodiment and Embodiment 1 lies in the fuel cell subsystem 1 with a controllable thermal boundary. Wherein, the heat-regulating component is composed of a heat-regulating plate 7 attached to the outside of the current collector 6, a heating sheet 8 attached to the outside of the heat-adjusting plate 7, and a heat-insulating plate 9 attached to the outside of the heating sheet 8. Outside the plate 9, the heat regulating plate 7 cooperates with the thermophysical quantity follower PID controller 12, which can regulate the thermal boundary conditions of the fuel cell, and the heat insulating plate 9 can reduce the heat loss from the heating plate 8 to the end plate 10. The active area of the core component of the monolithic battery is 25cm 2 The plate material is expanded graphite with a thickness of 2mm and an active area ratio of 0.4; the current collector 6 is made of gold-plated brass with a thickness of 1mm; the heat reg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com