Control method of efficient multi-stage drying system

A drying system and control method technology, which is applied in the direction of non-electric variable control, control/regulation system, and simultaneous control of multiple variables, etc., can solve the problem of limited improvement of heat pump drying energy efficiency and lack of high-efficiency multi-stage drying system , less refrigeration compressor circulation and other issues, to achieve the effect of avoiding manual operation, high energy efficiency, and low power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

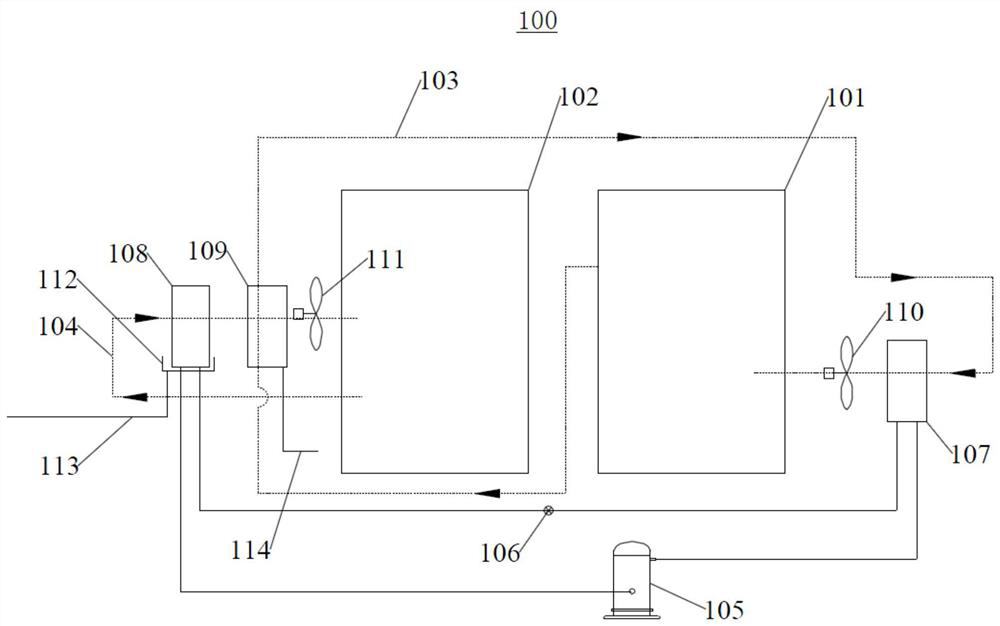

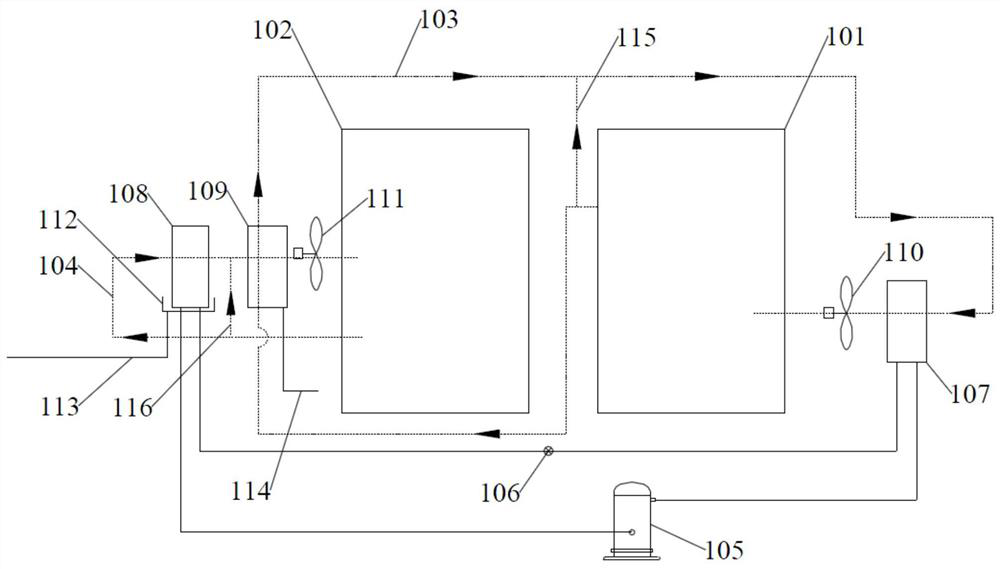

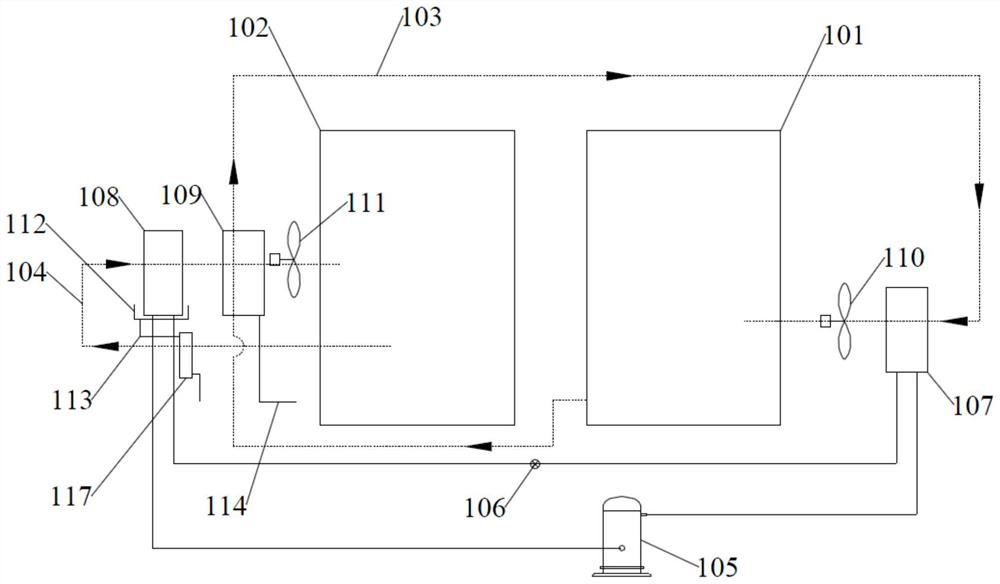

[0070] This embodiment provides a control method for an efficient multi-stage drying system, such as figure 1 As shown, the high-efficiency multi-stage drying system includes a first drying area 101, a second drying area 102, a first air duct 103, a second air duct 104, a compressor 105, a throttling device 106, a first air exchange Heater 107, second heat exchanger 108, first heat exchange assembly 109, first fan 110 and second fan 111;

[0071] The control method of the high-efficiency multi-stage drying system is executed by a controller, and the control method of the high-efficiency multi-stage drying system includes the following steps:

[0072] S1. Receive the high-efficiency multi-stage drying system start request, output the fan start command to the first fan 110 and the second fan 111, output the throttling device start command to the throttling device 106, and output the compressor start command to the compressor 105;

[0073] S2. Receive and process the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com