Examination test device and method for ultrahigh-temperature high-pressure stop valve

A test device and stop valve technology, applied in mechanical valve testing, liquid tightness measurement using liquid/vacuum degree, etc., can solve problems such as valve ablation, valve structure deformation, large pressure loss, etc., to improve opening response time , Prevent strong impact, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

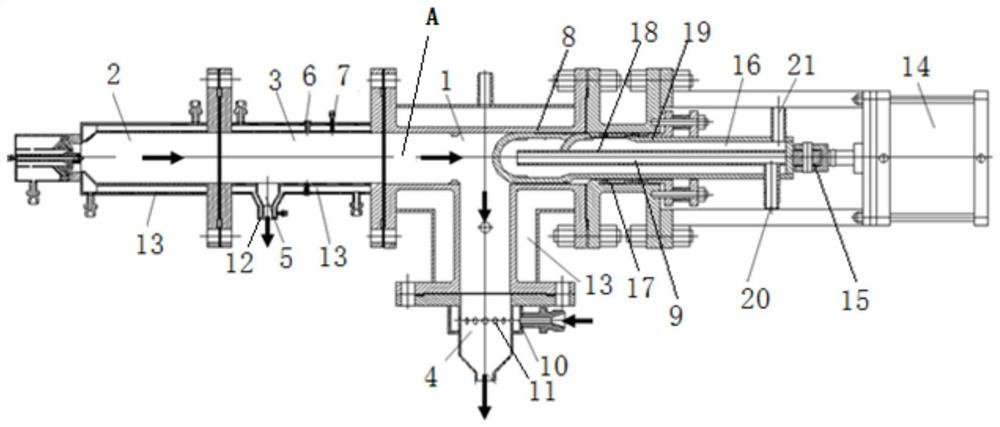

[0060] Such as figure 1 As shown, this embodiment provides an ultra-high temperature and high pressure cut-off valve assessment test device, including a cut-off valve test piece 1, an oxygen-enriched burner 2, a rectification measuring tube 3, an exhaust gas supplementary pressure nozzle 4, and an adjustable nozzle 5 , temperature measuring point 6 and pressure measuring point 7;

[0061] The cut-off valve test piece 1 is consistent with the air flow channel diameter and air flow form of the actual ultra-high temperature and high pressure cut-off valve, and the size and material of the valve core are consistent, which includes the shell 8 and the valve core assembly 9;

[0062] The gas inlet of the housing 8 is connected to the oxygen-enriched burner 1 through the rectifying measuring tube 3, and the gas outlet of the housing 8 is connected to the exhaust pressure injection pipe 4, thereby forming a gas channel A;

[0063] The spool assembly 9 is installed on the housing 8, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com