Safe drying device of wooden artificial board production line

A drying device and production line technology, applied in drying, dryer, veneer drying and other directions, can solve the problems of prolonging processing time and reducing the processing efficiency of artificial boards, and achieving the effect of strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

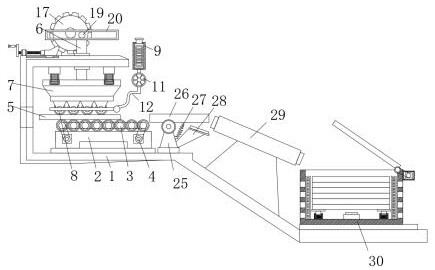

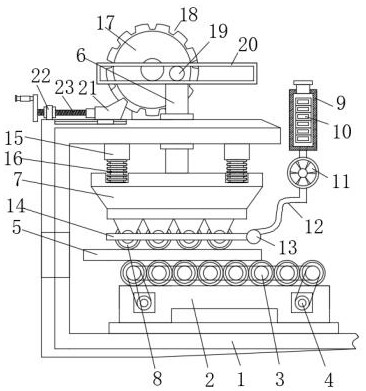

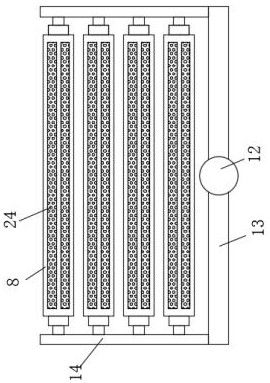

Embodiment 1

[0026] refer to Figure 1-7, a safe drying device for a wood-based panel production line, comprising a fixed seat 1, the top of the fixed seat 1 is fixedly connected with a transport platform 2, and the top of the transport platform 2 is rotatably connected with a plurality of transmission rollers 3 connected by transmission. The table 2 is provided with two driving motors 4 that drive the transport rollers 3 to rotate. Wood materials 5 are placed on the tops of the plurality of transport rollers 3. The fixed seat 1 is longitudinally slidably connected with a lifting rod 6, and the bottom of the lifting rod 6 is fixedly connected with a Adjusting seat 7, the bottom of adjusting seat 7 is rotatably connected with a plurality of extruding wheels 8, and extruding wheel 8 is hollow structure, and the bottom of a plurality of extruding wheels 8 all contacts with the top of wood raw material 5, and the top of fixed seat 1 The top is rotatably connected with an adjustment wheel 17, a...

Embodiment 2

[0028] This embodiment is improved on the basis of Embodiment 1:

[0029] In this embodiment, the fixed seat 1 is fixedly embedded with a linear bearing, and the lifting rod 6 runs through the inner ring of the linear bearing and is slidably connected with the inner ring of the linear bearing. Using the linear bearing can improve the stability of the vertical sliding of the lifting rod 6 .

[0030] In this embodiment, the brake assembly includes a plurality of slots 18 annularly opened on the outside of the adjustment wheel 17. The top of the fixing seat 1 is slidably connected with a block 21, and the block 21 is matched with the slot 18. The fixing seat 1 The top of the fixed block is fixedly connected with a fixed block 22, and the fixed block 22 is rotatably connected with a threaded adjustment rod 23. The two ends of the threaded adjustment rod 23 extend to the two ends of the fixed block 22 respectively, and one end of the fixed block 22 extends to the inside of the clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com