A Position Control Method of High Response Servo Proportional Valve

A servo proportional valve and control method technology, applied in servo motor components, fluid pressure actuating devices, mechanical equipment, etc., can solve the problem that PID parameters cannot adapt to high-frequency and low-frequency given signals at the same time, to ensure stability, The effect of adapting to complex working conditions and flexible control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will now be described in further detail with reference to the accompanying drawings.

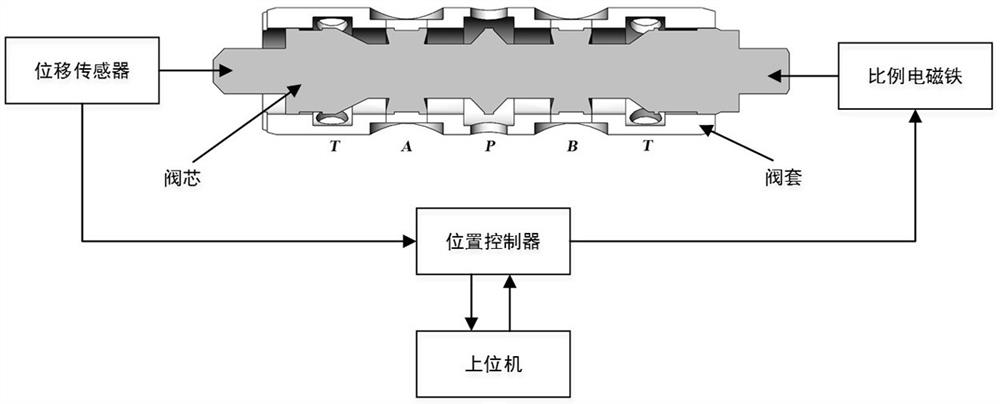

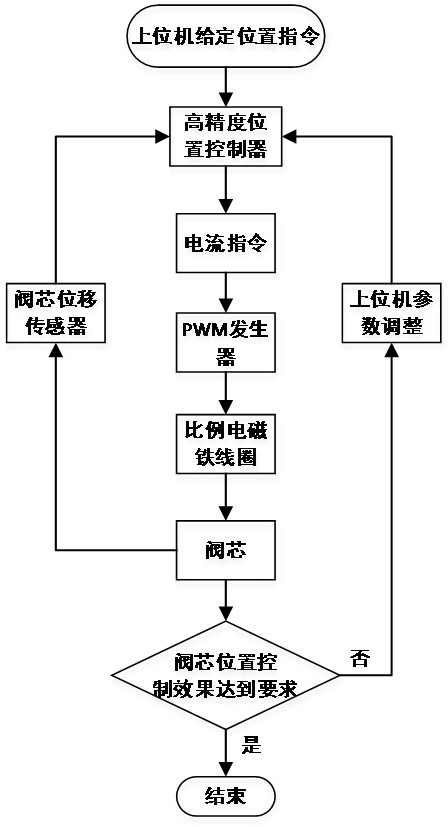

[0029] as attached Figure 1-3 As shown in the figure, a high-response servo proportional valve position control method proposed by the present invention, in one embodiment of the present invention, realizes a direct-acting electro-hydraulic proportional valve driven by a single electromagnet with valve core displacement feedback . The direct-acting high-response proportional valve consists of a valve body, a position controller and an upper computer. The valve body includes a single proportional solenoid, valve core, and valve sleeve. The proportional electromagnet receives the current output by the position controller to generate a thrust to the valve core. The electromagnetic thrust, spring force, hydraulic force and friction force work together with the valve core to control the valve core position. The position of the valve core is detected by the displac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com