Composite-layer pavement brick and preparation method thereof

A composite layer and pavement brick technology, which is applied to roads, roads, pavement details, etc., can solve the problems of poor bearing capacity, short service life, and easy wear and tear of composite pavement bricks, and achieve good anti-skid performance, low overall cost, Not easy to fall off effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

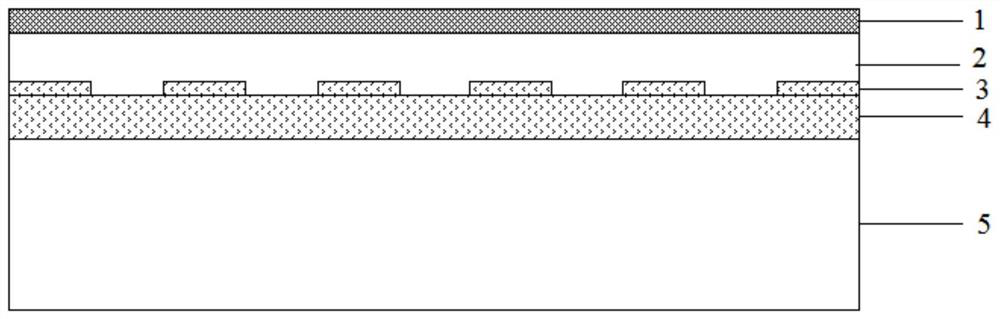

[0025] The first aspect of the embodiment of the present application provides a method for preparing a composite layer pavement brick, comprising the following steps:

[0026] S01. Provide the surface layer raw material mixture and the bottom raw material mixture of the composite layer pavement bricks respectively;

[0027] S02. Provide a mold, and spray concrete additives on the inner surface of the bottom of the mold to obtain an additive layer;

[0028] S03. Place the surface layer raw material mixture on the surface of the auxiliary agent layer, and perform vacuum pressing to obtain a pre-surface layer;

[0029] S04. Opening grooves on the surface of the pre-surface layer away from the auxiliary agent layer, placing gravel in the mold and performing pressing treatment to obtain the pre-connection layer;

[0030] S05. Lay the bottom layer raw material mixture on the surface of the pre-connection layer and carry out vacuum exhaust treatment to form a pre-bottom layer, and o...

Embodiment 1

[0087] Composite layer pavement brick and its preparation method

[0088] Composite ply brick

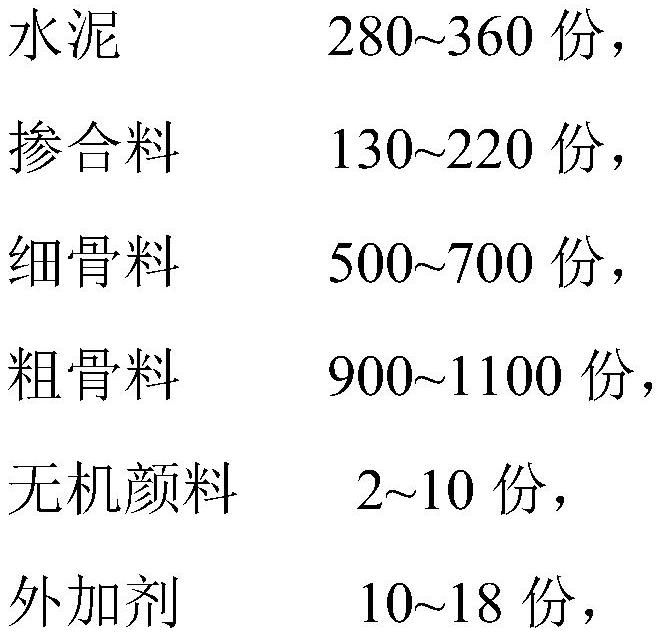

[0089] The composite ply pavement brick comprises a surface layer and a bottom layer, wherein the surface layer raw material mixture includes the following raw materials in parts by weight:

[0090]

[0091] Control the mass ratio of the added water to the cement of the surface layer to be 0.28:1; and / or,

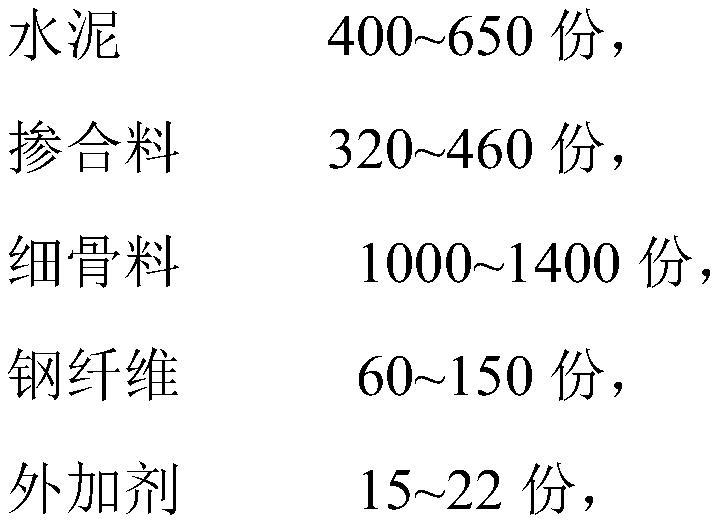

[0092] The bottom raw material mixture comprises the raw materials of following parts by weight:

[0093]

[0094] Control the mass ratio of the added water to the bottom cement to be 0.16:1;

[0095] Among them, the cement is selected from Portland cement with a strength > 42.5MPa; the average particle size of the admixture is 5-30 μm; the average particle size of the fine aggregate is 2-4.75mm; the average particle size of the coarse aggregate is 4.75- 25mm; the diameter of the steel fiber is 0.1-0.25mm, and the length is 10-20mm.

[0096] A kind of preparation me...

Embodiment 2

[0106] Composite layer pavement brick and its preparation method

[0107] Composite ply brick

[0108] The composite ply pavement brick comprises a surface layer and a bottom layer, wherein the surface layer raw material mixture includes the following raw materials in parts by weight:

[0109]

[0110] Control the mass ratio of the added water to the cement of the surface layer to be 0.32:1;

[0111] The bottom raw material mixture comprises the raw materials of following parts by weight:

[0112]

[0113] Control the mass ratio of added water to bottom cement to be 0.2:1;

[0114] Among them, the cement is selected from Portland cement with a strength > 42.5MPa; the average particle size of the admixture is 5-30 μm; the average particle size of the fine aggregate is 2-4.75mm; the average particle size of the coarse aggregate is 4.75- 25mm; the diameter of the steel fiber is 0.1-0.25mm, and the length is 10-20mm.

[0115] A kind of preparation method of composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com