Pressure-stabilizing and temperature-adjusting device for preparing flexible glass by slit method and control method

A flexible glass and temperature regulating device technology, applied in glass forming, glass forming, glass manufacturing equipment, etc., can solve the problems of easy aging, affecting the texture and life of electronic products, low temperature resistance, etc., to avoid crystallization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

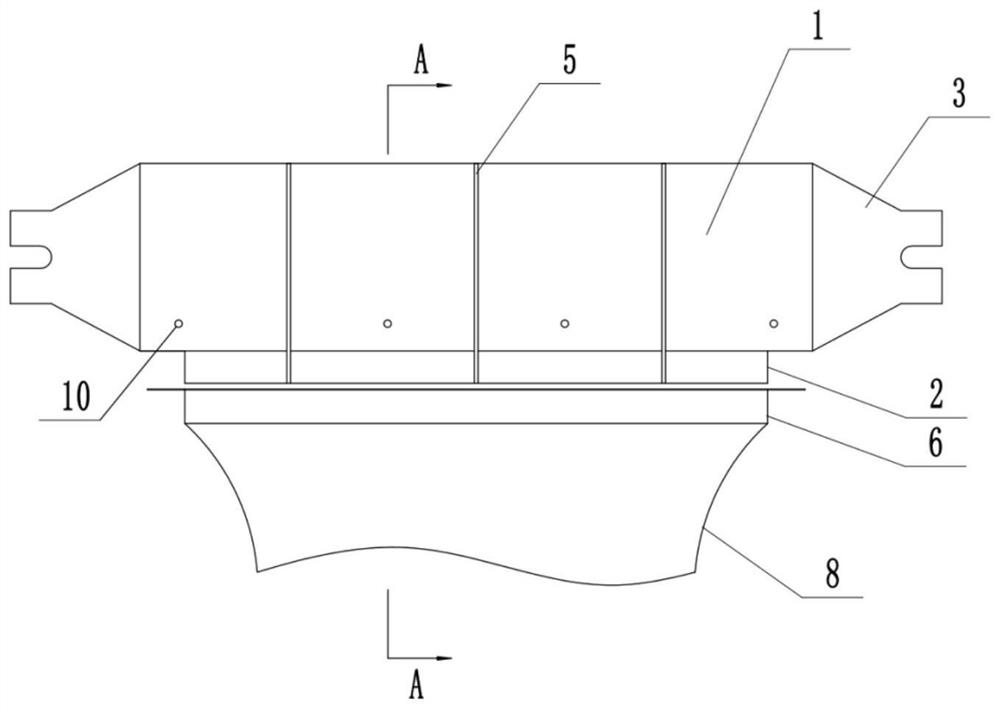

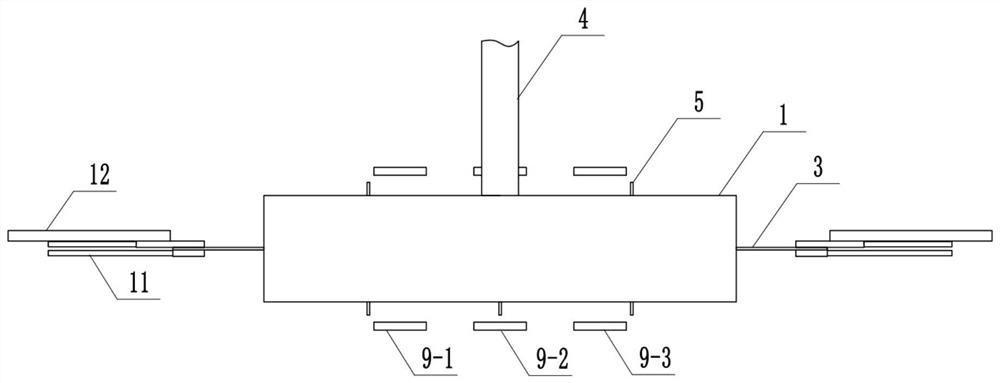

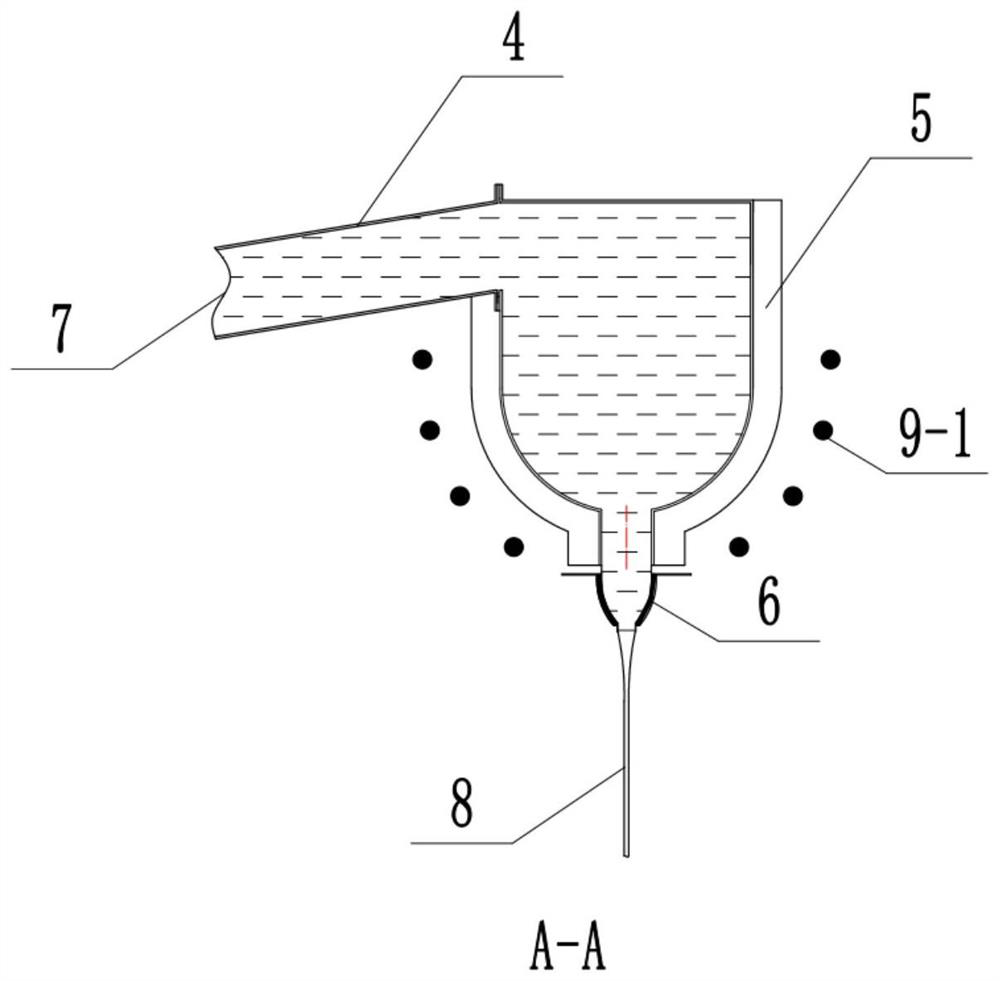

[0031] Such as Figure 1-3 As shown, the present invention provides a pressure-stabilizing and temperature-regulating device for preparing flexible glass by the slit method. , the slit device 6 communicates with the inner cavity of the pressure-regulating chamber 1 by means of the outlet 2 of the regulating chamber. The formed chamber has an arc-shaped pot-like structure in cross section, and electrode joints 3 are arranged at both ends of the pressure-regulating chamber 1 .

[0032] Insulation materials are installed around the infusion pipeline 4 to prevent heat loss. The glass liquid enters the pressure stabilizing and regulating room 1 through a plurality of infusion pipelines 4. The stabilizing and regulating room 1 adopts a closed-top structure. The influence of surface fluctuations. On the other hand, ensure that the temperature field is not easily affected by the external air flow, and reduce the influence of the flow of glass liquid on the pressure field in the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com