Feeding hopper with pretreatment function for movable crushing station

A crushing station and pretreatment technology, applied in the direction of plastic recycling, recycling technology, mechanical material recycling, etc., can solve the problems of reducing crushing efficiency and increasing crushing difficulty, and achieve the goals of improving crushing efficiency, rapid crushing treatment, and improving protection performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

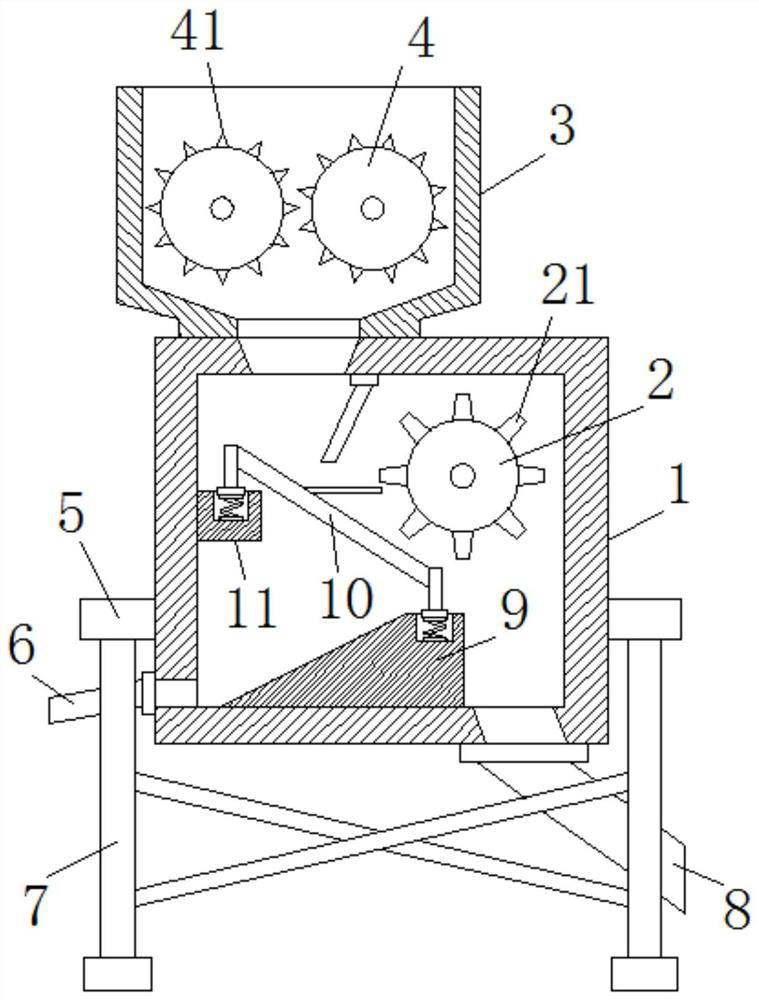

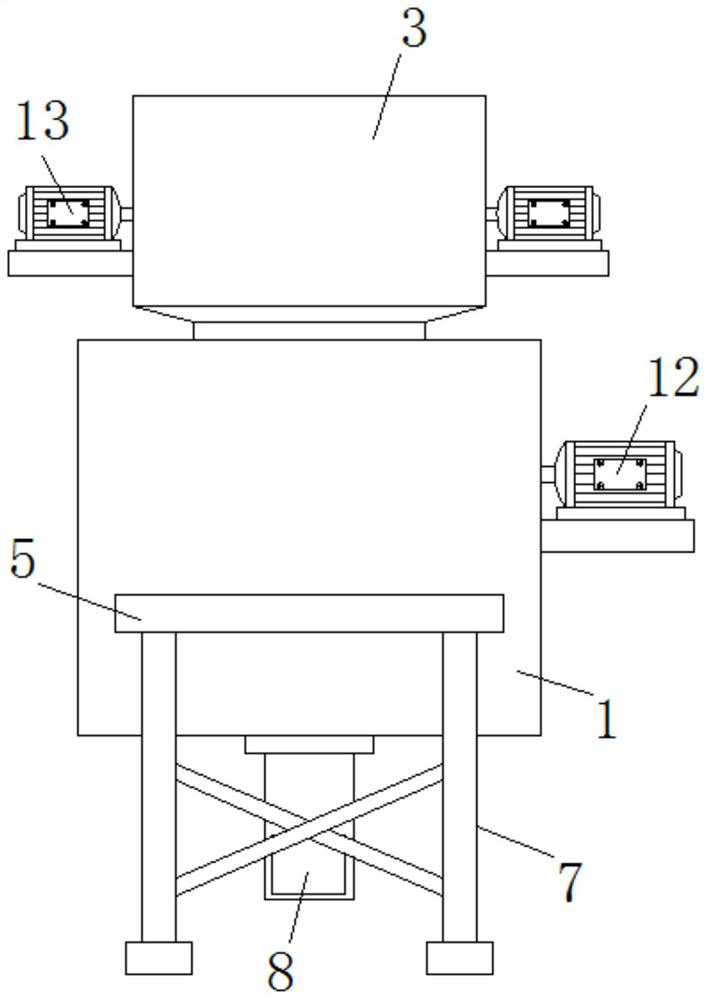

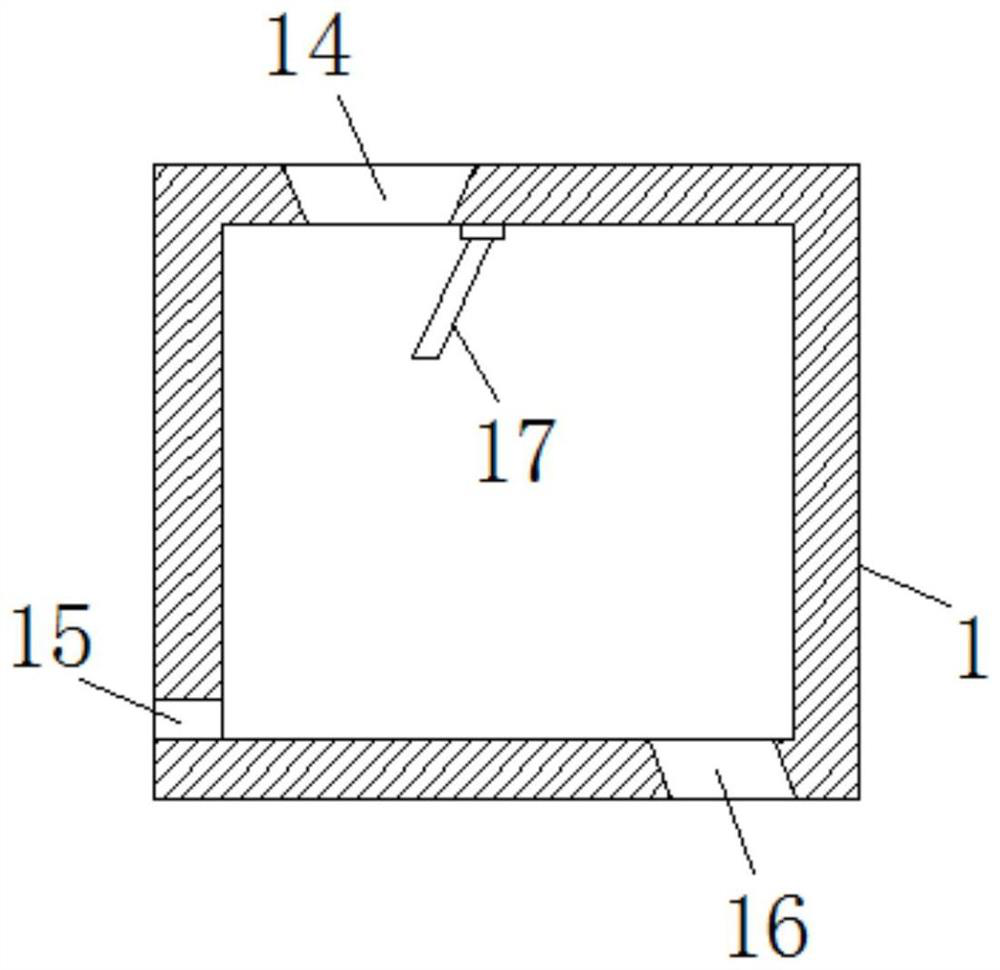

[0026] Example: such as Figure 1-6 As shown, a feed hopper with a pretreatment function for a mobile crushing station in the present invention includes a first bucket body 1, and a pusher roller 2 is installed in rotation in the first bucket body 1, and on the outer wall of the first bucket body 1 And the position corresponding to the pushing roller 2 is fixedly installed with a first motor 12, the output end of the first motor 12 is inserted into the first bucket body 1 and fixedly connected with the pushing roller 2, and the inner bottom wall of the first bucket body 1 A first support mechanism 9 is fixedly installed, a second support mechanism 11 is fixedly installed on the inner wall of the first bucket body 1, and a water filter mechanism 10 is fixedly installed between the second support mechanism 11 and the first support mechanism 9, and the filter The water mechanism 10 is inclined to the side of the first support mechanism 9. Two side plates 5 are symmetrically fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com