Garbage treatment method

A garbage disposal and garbage technology, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems of easily affecting the surrounding environment, difficult to collect sewage, etc., to reduce energy consumption, reduce labor costs, use handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

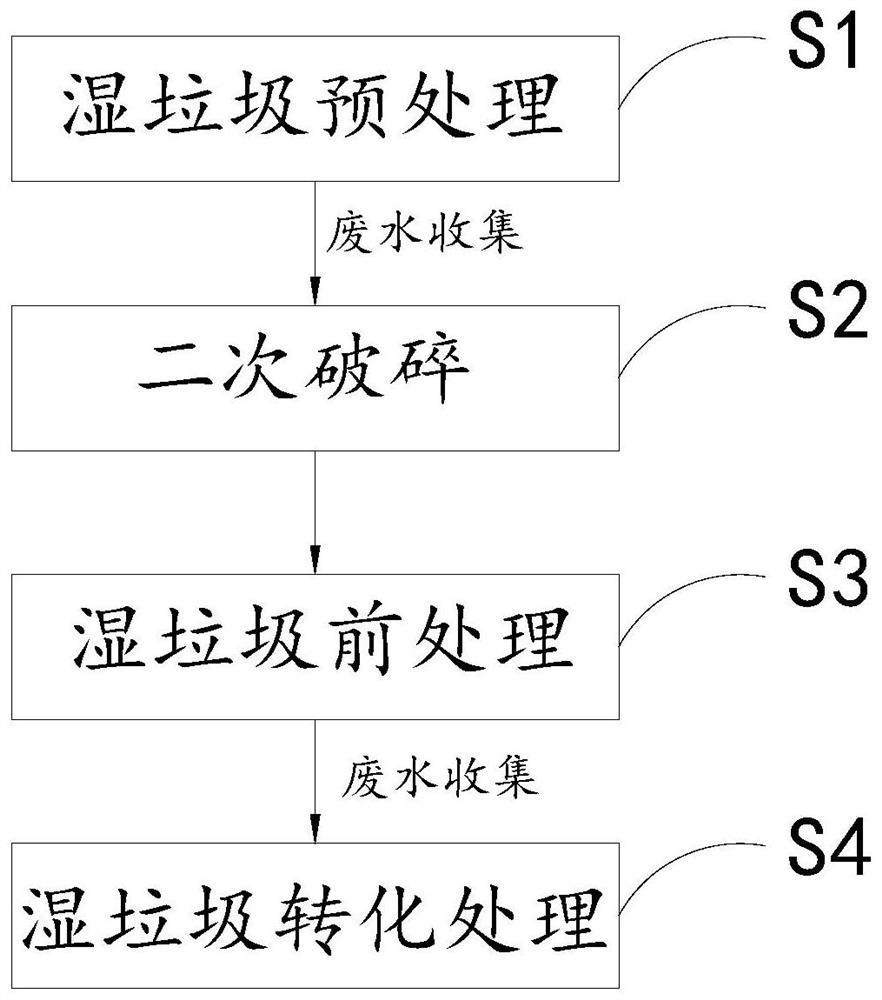

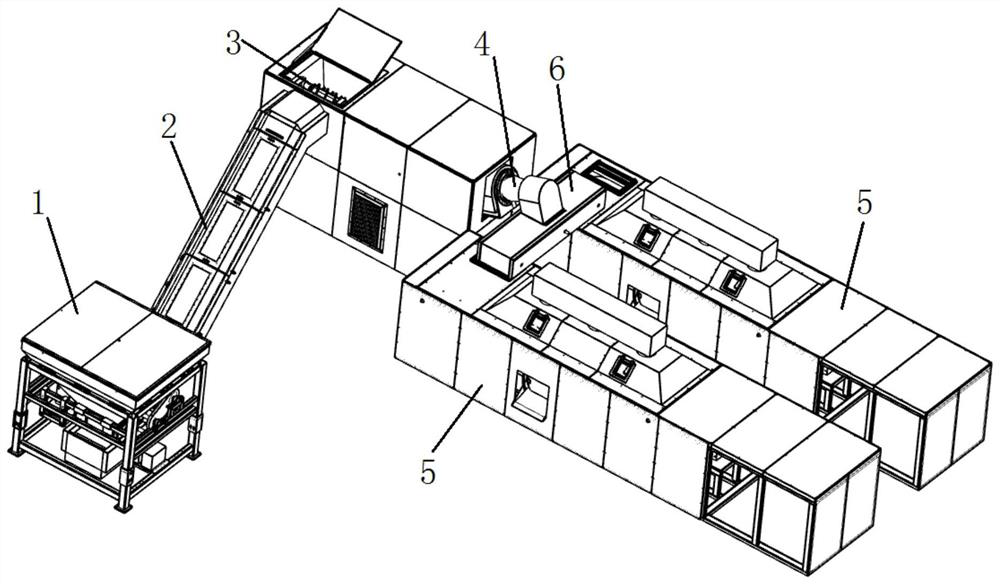

[0062] see Figure 1-11 As shown, the present embodiment provides a garbage disposal method, including:

[0063] S1: Wet garbage pretreatment, wet garbage is pre-shredded, and the wet garbage after pre-shredding is sent to the next process. During the transmission process, the waste water generated by the wet garbage is collected;

[0064] S2: secondary crushing, the wet garbage after the pre-crushing treatment is subjected to secondary crushing;

[0065] S3: Pre-treatment of wet garbage. The wet garbage after the secondary crushing is stirred, dehydrated and desalted, and the waste water generated during the transfer, stirring, dehydration and desalted treatment of the wet garbage is collected at the same time;

[0066] S4: Wet garbage conversion treatment, the wet garbage that has completed the wet garbage pre-treatment is sent to the reaction chamber 5 for wet garbage conversion treatment.

[0067] In the present invention, through the above-mentioned garbage treatment me...

Embodiment 2

[0071] see Figure 3-5 As shown, this embodiment is optimized and limited on the basis of the above-mentioned embodiment 1.

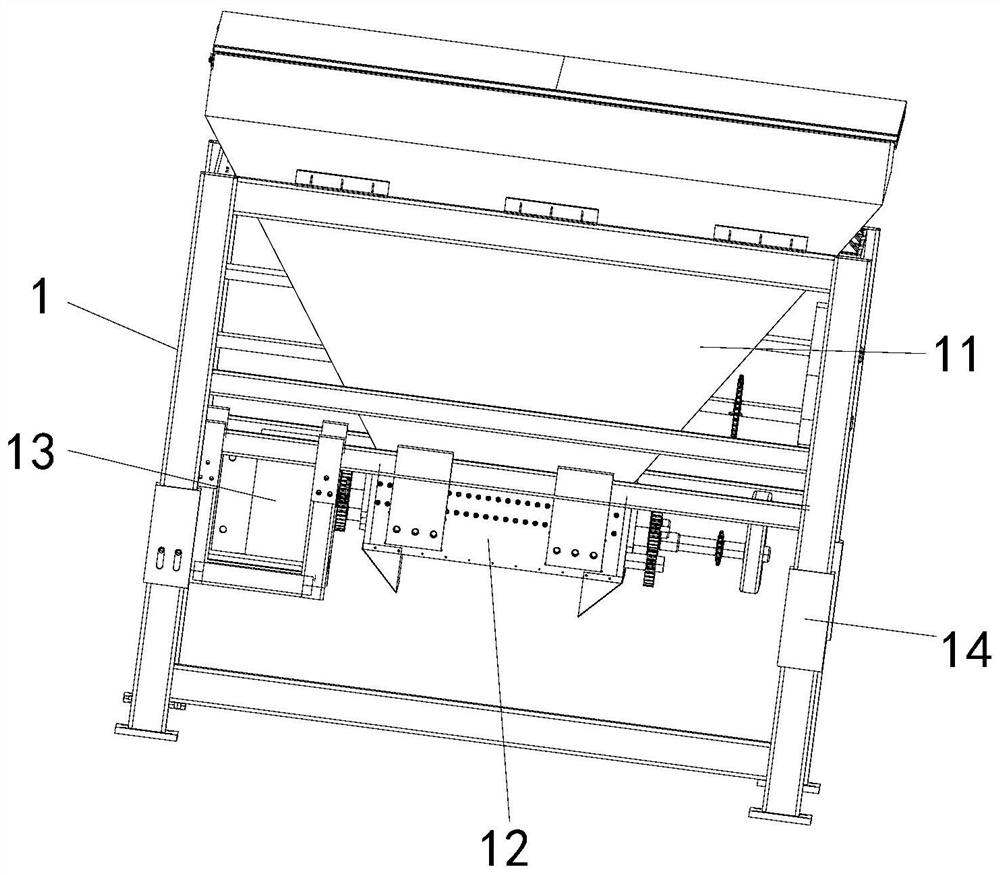

[0072] Wet waste pretreatment includes:

[0073] The wet garbage is cut by the front crushing device 11 during the rotation process, and the wet garbage is cut and stirred through the cutting process, which can reduce the difficulty of crushing and make it easier for large-volume wet garbage to become small-volume wet garbage;

[0074] Spraying the wet garbage while cutting, can reduce the salt concentration in the wet garbage, and can also dilute the smell of the wet garbage (garbage odor);

[0075] After passing through the crushing device 12, the wet garbage is crushed during the rotation process;

[0076] Wherein, the front crushing device 11 and the rear crushing device 12 are simultaneously driven by a driving member 13 .

[0077] In the present invention, one driving member 13 can simultaneously provide power for the front crushing device 11 a...

Embodiment 3

[0079] see Figure 3-5 As shown, this embodiment is optimized and limited on the basis of the above-mentioned embodiment 2.

[0080] The front crushing device 11 includes 2 rotating shafts 111 with cutters, and the rear crushing device 12 includes three rotating shafts 121 with gear blades arranged side by side. The spacing is adjusted. In the present invention, adjusting positions can be respectively set at the two ends of the two outer rotating shafts, and adjusting parts can be set on the adjusting positions so that the rotating shafts can move left and right, so as to adjust the distance between the three rotating shafts. The size of the spacing can be changed according to the actual size of the garbage, which can be applied to wet garbage of different specifications and has higher flexibility.

[0081] In the present invention, the secondary crushing also includes stirring and cutting the wet garbage, and then performing secondary crushing on the wet garbage; Some adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com